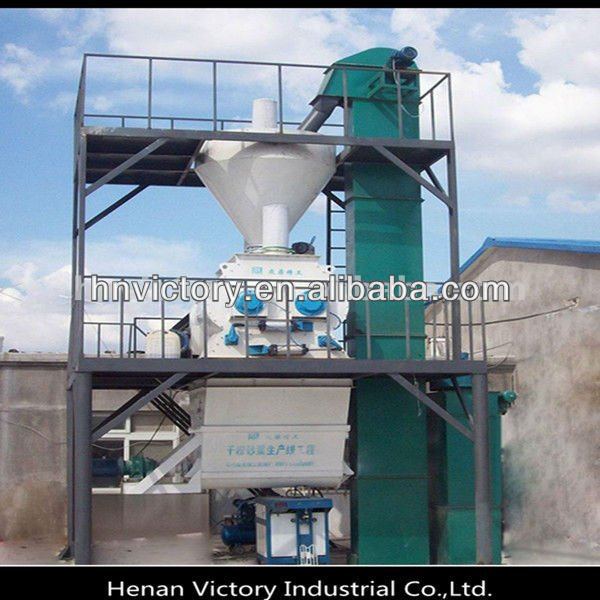

High Quality Basic Type Dry Mortar Plant

| Condition:New | Application:Dry Mortar Blending | Production Capacity:5-50t/h | Place of Origin:Henan China (Mainland) |

| Brand Name:VICTORY | Model Number:BASIC | Dimension(L*W*H):6000*6000*6000mm | Certification:ISO9001 |

| Warranty:12 months | After-sales Service Provided:Engineers available to service machinery overseas | Name:Basic Type Dry Mortar Plant | Color:According to your requirement |

| Manpower:3-5 People | Driven:Electric driven | Packing:Valve prot packing or open type packing |

High Quality Basic Type Dry Mortar Plant

1. Good dispersibility: the inside of the mixer use a unique design, can effectively dispersed polypropylene fiber and wood fiber, completely solved the problem which caused by the proportion of different materials and fiber segregation.

2. Wide range of application: the equipment can produce different types of mortar. Such as: Masonry mortar, plaster, insulation mortar, decorate mortar and so on.

3. Cost-effective: Machine for external wall insulation and decorative mortar. Low investment and high efficiency. Avoid waste of resources.

4. Easy to operate: Small footprint, low powder consumption, easy operation. The output is 3-50T/h, 3-5 people can control it.

Feature:

1.Small investment and best for individuals

2.Automatic feeding, dosing and packing

3.High standard of environment performance

4.With high precision and stability.

5.Small covering area

6.Easy to operation

7.Easy to maintenance

Environmental friendly:

1.To solve the dust product during the dry powder mortar production, different dedusting systems are a dopts in different positions. The dedusting system of the drying equipment adopts the pulsed jet cloth filter, the powder collected can be recycled, realizing zero release.High efficient screening system. Different screening machines are adopted in different steps, which can effectively improve the energy utilization and screening efficiency.

2.The raw sand can be sent into the drying equipment only after separating the large aggregate by the trommel screen. Itcan effectively reduce the failure rate of the drying equipment and improve the energy utilization.

3.After separating the materials over criteria by the vibrating screen, the dry sand will be lifted to the top of the silo by the bucket elevator, hen process the sand by the vibrating classification screen, ensuring the strict grading of the mortar.

It can produce the following kinds of mortar:

1) Masonry mortar

2) Thin and smooth wall mortar

3) Hand-plastering screeding mortar

4) Colored coating mortar

5) Water-proof mortar

6) Plaster powder

7) Wall plastering mortar

8) Ceramic tile adhesive mortar

9) Self-leveling mortar

10) Heat-preservation mortar

Technical Parameters of Dry MortarProduction Line:

| Production line mode | Output | Occupied area | Equipment heigh | Remark of batching and packing |

| Simple | 1-15t/h | 40m2 | 5-10m | Manual batching and packing |

| Basic | 5-15t/h | 40-60m2 | 6-10m | Manual batching, automatic packing |

| Semiautonmatic of serial mode | 5-15t/h | 40-80m2 | 8-12m | Automatic batching of coarse material, manual batching of additive, automatic packing |

| Semiautonmatic of tower mode | 5-50t/h | 40-100m2 | 10-25m | the same to serial semiautomatic made |

| Fully automatic of tower mode | 5-50t/h | 60-500m2 | 10-25m | Automatic batching of all raw material and packing |

Basic Type Dry Mortar Plant Diagram:

Our company strictly execute ISO9001 International Quality Management System Standards and implement the scientific concept of "constant development ″. We can offer all kinds of production lines according to different requirments of customer. PLS contact us if you have any enquiry about our machines! JUST Wating for you !

Henan Victory Industrial Co.,Ltd

Fax:0086 371 63986697

Tel: 0086 371 63987697

| Packaging Detail:Basic Type Dry Mortar Plant adopt in Standard Export Wooden Case |

| Delivery Detail:withine 15 days once get advanced payment |