High Pressure Suspension Grinder--Hot Sales!!!

| Condition:New | Type:Grinder,YGM65,YGM75,YGM85,YGM85B,YGM95,YGM130,YGM160 | Product Type:Paint | Place of Origin:Henan China (Mainland) |

| Brand Name:Dahua | Model Number:R series | Certificate:ISO9001:2008 | Guarantee:1 year |

| Used for:Grinding Barite,calcite,potash feldspar,talcum,marble, | Output size:0.0613-0.033mm | Motor:Chinese Brand or as customer request | Max.feed size:35mm |

Introduction of High Pressure Suspension Mill

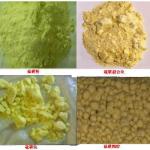

The machine is suitable for grinding the barite,limestone,kaollnite,ceram and slags,etc,which below scale 9.3 of Moth and below 6% shadness and 280-odd sorts of non-inflammable and non-explosive stuff in the trades of mining,metallurgy,chemical engineering and building material for high fine powder generating and processing.The product size is adjustable in the range of 80-425 mesh.It is possible to produce 30-80mesh coarse powder through special device in the machine.

Work principle of High Pressure Suspension Mill

In the main frame,the 100-1500kg powered pressure spring is fixed to the roller suspender.After grinding machine is put into effect,the roller rotates around the main shaft,and rolls closely against the ring effected by the high pressure is 1.2times higher than of the raymond grinding machine under the same power condintion and the output is raised to asubstant degree.When the stuff is loaded into the grinding cavity,it is shoveled into the space between the roller and the ring for grinding.The resulted pwoder is routed to the separator along the circulation wind of the blower and the standard fine powder is guided to the cyclone collector as final product and large size stuff falls back to the grinder for regrinding.The circulation wind returns to the blower to repeat the above process and the remainder wind enters into bag deduster for purification.When a certain degaree of wear of roller and ring is caused,it is recommend to adjust the length of the spring to maintain the constant pressure between the roller and the ring.As a result,the stable output and fineness are ensured.

Technical Parameter of High Pressure Suspension Mill

Model | No.of Roller | Roller Size(LxR) (mm) | Inside Diameter of Ring(mm) | Max.Input Size(mm) | Output Size(mm) | Capacity(t) | Main Frame Power(kw) | Dimension (m) |

YGM65 | 3 | 210x150 | 650 | 15 | 0.613-0.033 | 0.4-1.8 | 15 | 4.1x3.3x4.5 |

YGM75 | 3 | 260x150 | 780 | 15 | 0.613-0.033 | 1-3 | 18.5 | 4.3x3.3x5.1 |

YGM85 | 3 | 270x140 | 830 | 20 | 0.613-0.033 | 1.2-4.6 | 22 | 5.3x4.1x5.2 |

YGM85B | 3 | 270X150 | 830 | 20 | 0.613-0.033 | 1.2-4.6 | 22 | 5.6x3.4x4.9 |

YGM95 | 4 | 310x170 | 950 | 25 | 0.613-0.033 | 2.1-5.6 | 37 | 7.1x5.9x7.9 |

YGM130 | 5 | 410x210 | 1280 | 30 | 0.95-0.033 | 2.5-9.5 | 75 | 7.85X8X9.7 |

YGM160 | 6 | 440x270 | 1600 | 35 | 1.9-0.045 | 8-16 | 132 | 12.55X5.7X8.355 |

| Packaging Detail:Standard export packing |

| Delivery Detail:20days |