High Perfromance Large Capacity Coal Gasifier Plants

| Type:Hot Air Furnace,Other | Place of Origin:Henan China (Mainland) | Brand Name:Prochange | Model Number:HX-1 |

| Color:As request | After-sale technic service:Lifetime | Guarantee:1 year | Factory visit:Welcome |

| ID:10220244916 | Material:Steel | Industrial fuel used:solid, liquid and gas fuel | State:New |

| Installation:Our engineer guiding |

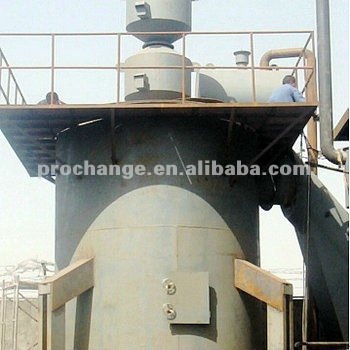

Coal Gasifier Plants

Description

Overview of gas producer

Industrial fuel currently used are: solid fuel, liquid fuel and gas fuel three types. From the international development trend, gas is more widely used.

Gas fuel commonly referred to as gas. According to its mode of production can be divided into two categories: natural gas and coal gas. Natural gas extracted from the ground by drilling wells devices, mine gas, oil mixed with natural gas and biogas.

Producer gas products are solid fuel (coal or coke) after a thermal processing gases, namely oxygen or oxygen compounds (steam, carbon dioxide) through the high-temperature solid fuels (coal, coke) layer, which play a role in oxidative organic matter (air, water vapor) as the gasification agent, to generate hydrogen, carbon monoxide and methane gas mixture referred to as gas. By gas agents were divided into three types as follows:

1. the air gas: air as the gasification agent.

2. the water gas: the steam for the gasification agent.

3. the mixed gas: The air and water vapor as the gasification agent.

The three gas components are as follows: (expressed as a percentage by volume)

| Gas composition Gas name | H2 | CO | CO2 | N2 | CH4 | O2 |

| Air gas | 2.6 | 1.00 | 14.2 | 7.2 | 0.5 | 0.2 |

| Mixed gas | 13.5 | 27.5 | 5 | 52.8 | 0.5 | 0.2 |

| Water gas | 48.4 | 38.5 | 6 | 6.4 | 0.5 | 0.2 |

Our company designs and manufactures gas producer mixed air and water vapor as the gasification agent. As the principle of reasonable gasification furnace, simple design, low investment, easy to use, security, operation and maintenance is simple, easy to grasp, so more suitable for medium and small factories.

For all types of metal heat treatment furnaces, ceramic kilns, melting furnace, copper refining furnaces, forges, forging furnaces, metal furnace, hot-dip galvanizing furnace, drying furnace, glass industry, chemical industry, ceramic industry, cable supporting the provision of gas and other industries.

Producer structure

Full water jacket structure, self-produced steam can be done directly through the gasification agent into the gas stove use. Cover the use of different fire-resistant insulation materials double casting.

Canadian coal sector

Double Bell adding coal, automatic stokers and hydraulic drive under the bell on the flapper structure, according to the need to increase coal sieve.

| Packaging Detail:Standard export container, bare main machine, motors and small parts are packed in wooden cases. |

| Delivery Detail:30 days after placing the order |