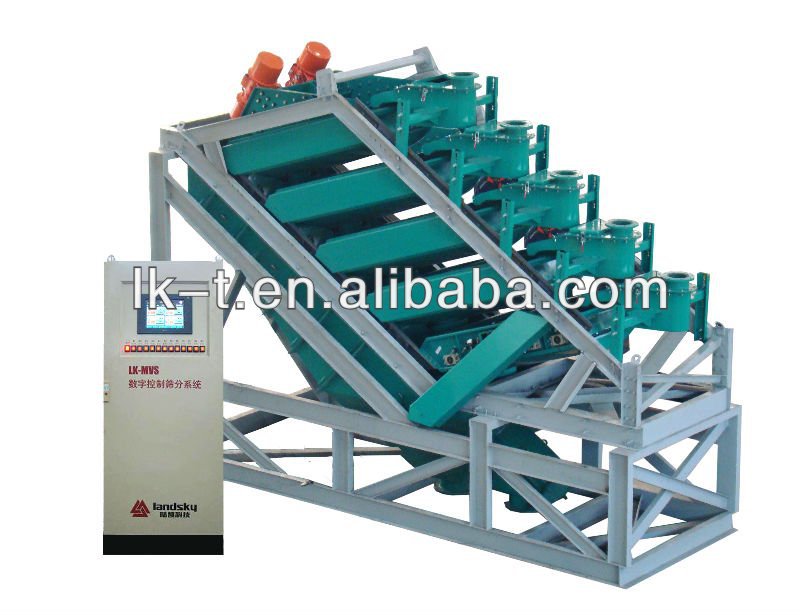

High Frequency Stack Sizer Vibrating Screen for Ore Fines separation and classification

| Condition:New | Type:Vibrating,Classification | Application:Ore,Mine separation | Place of Origin:Beijing China (Mainland) |

| Brand Name:Landsky | Model Number:FMVS | Voltage:380V / 460V | Weight:9t |

| Certification:ISO9001 | After-sales Service Provided:Engineers available to service machinery overseas |

Introduction of Composite High-Frequency Vibrating Screens

Principles of Vibration

1 The vibration on deck is jointly done by two systems: linear and electromagnetic exciter. With a strong intensity and frequencey (50Hz), electromagnetic vibration makes the material down the sieve easily; with a large amplitude, a low frequency (16 or 25Hz) and a throwing force, the linear vibration facilitates an easy loosing and conveying of the material.

2,All this serves as one of the best combination for screening vibration technology in the present world, thus more efficient than single vibration source.

3. This combination is widely applied in the fields of ore concentration, coal preparation, construction materials and chemical industry etc.

4, The dry screening is for fine classification (-10mm) of coal, brick making, chemical industry and fertilizer etc. It can be designed as single single-channel and double channel. The wet screening screens have two seriez: classification and dewatering. The classification screens are for classifying the fine material and can be designed as stack sizer(1~5); while dewatering screens are normally one stack for tailing, quatz sand and coal slurry.

Performance characteristics

1.For the multi-stack composite vibrating screen, the feeding is made in a paralleled circuit by multi channels. It covers an small area so applicable in limited room. Each screen box is fed independently which guarantees the uniform distribution of feed. The overflow and underflow are discharged in different chutes and not mixed together.

2.The screen box and chutes are first sand blasted and then coated by the polyurethane. The 2mm PU cover enables the screen to be high resistant, anti-corrosion and rust-proof, so that improves the life span of the machine.

3.The screen box is molded by bending the steel sheet integrally, and whole equipment is given heat treatment to eliminate the stress and the hidden danger of side plate cracking and welding off.

4.A brand new D-model exciter is applied in the machine. The balanced output in the two ends reduce the mass being vibrated.

5.Matched with the polyurethane mesh produced by Landsky Tech, the screen can work with high efficiency for a longer time. Also the renewal of the PU mesh is easy.

Specification

| Model | Stack | Working area | Power | Application |

| FMVSk2020 | 1 | 4.0 | 5.40 | Wet Classifying |

| 2FMVSk2020 | 1(two meshes) | 4.0 | 5.40 | |

| D2F1014 | 2 | 2.8 | 3.06 | Wet Classifying & Dewatering |

| D3F1014 | 3 | 4.2 | 5.24 | |

| D4F1014 | 4 | 5.6 | 6.80 | |

| D5F1014 | 5 | 7.0 | 6.80 | |

| FMVS1235 | 1 | 4.2 | 5.00 | Dry Classify & Dewatering |

| FMVS2030 | 1 | 6.0 | 9.32 |

Multi-Stack

D-model Exciter (the newest patented technology)

Heat Treatment to Eliminate the Stress

the Multi-Stack Composite Vibrating Screen Frame after the Heat Treatment

Sand blasting

After Being Blasted by Sand

Part of the Frame

The Screen Frame and Chutes coated with Polyurethane

The Martin Roller Motor Specialized for the Composite Screen

The Application of Multi-Stack Composite Vibrating Screen On Sites

Introduction of Landsky

Established in 1997, with a registered capital of ten million RMB, Landsky technology Co. Ltd has become a scientific and technological development enterprise after many years’ sustained development. Our business comprehensively covers from A to Z: research design, manufacture, parts supply, marketing and service. It specifies itself in the field of research, development and manufacture of the flowsheet and equipment for process.

Our company locates in Beijing with the production base in Tangshan, Hebei Province, which covers an area of 48000 square meters.With a Research center and over 400 testing equipment, our company has an annual throughput of 1500 sets of electromagnetic high frequency screens, 40000 square meters stainless- steel wedge-wire welded mesh and 100,000 square meters stainless-steel woven-wire composite mesh. We have totally more than 200 employees up till now.

Warmly welcome to make visit of our production base!

| Packaging Detail:Wooden box and as required |

| Delivery Detail:Within 3 Months |