High Flow Bead Mill, bead mill centrifugal, bead mill micro(DCD)

| Place of Origin:Jiangsu China (Mainland) | Brand Name:SAILING | Model Number:DCD |

SAILING INTERNATIONAL INDUSTRIAL GROUP LIMITED | |||||

PRODUCT DETAILS | |||||

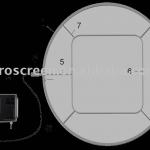

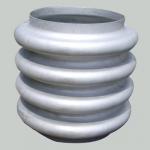

USAGE | DCD High Flow Bead Mill To provide the nano-and micron- level grinding and dispersion technology of hightech products in life with a better and more economical production solution. Advantage: a wide range of applications The excellent quality of bright-colored and high-resolution fashion mobile phones, TFT screens or laptops, and a large quantity of fashion automotive paint and bright-colored paint really show the outstanding dispersion characteristic of the model. It is more used the fields of paints and varnishes, agricultural chemicals, inks, chemicals, paper making and nanotechnology *High-quality color filter of TFT screen and PLC display screen; *More glorious car paint, high solids and water-based products; *Heavy coatings with higher resistance; *Nano-level grinding of photosensitive pigment makes it more brilliant, eyecatching; *In the production of high-quality dyeing paint, the enhanced color strength can lead to more economic benefits; *High-quality packaging and silver² ink with more gloss and transparency; *Super inkjet products with higher quality; *Obtaining higher quality and¾ economic benefits in research and production, with high requirements of product development in percentage and grinding Quick and easy operation The model is simple, easy to master, and all the maintenance can be completed quickly and easily. *It is very easy to add grinding media from the filling hole above; Do not discharge and grind the media, but the protective screen can be taken out of the closed mill; *Minimal cleaning fluid is required for replacement of the product; *Minimum time and cleaning are required for replacement of grinding media; *It is very simple to make the grinding chamber decline by an integral lifting device; *The grinding chamber can drop and rotate along the pivot. Good cooling performance *Products are pre-cooled in the eddy current guidance gap; *The effective stator and rotor of the grinding chamber are cooled on the outer layer; *Products are effectively cooled in the return zone at the bottom of the stator; *within grinding chamber of product flow, the effective stator and rotor are cooled; *The continuous eddy current of the product on the inner surface of the rotor cools the inner grinding chamber down strongly. Working principle The products to be ground go into the feed pump from the top, and are evenly spread on the upper part of the outer rotor with the balanced rotating rotor. The products are thoroughly pre-treated within the centrifuge area of the rotor and the cylindrical gap formed by the stator. In the next strong grinding belt, the interaction between the rotor and stator nails has a strong continuous changing impact on the grinding media, and the grinding media then acts on the products. In the bottom area of the stator, a mixture of the products and grinding media return and enter to the grinding chamber, and flows from the bottom to the top. Here, the grinding media is only affected on the surface of the stator nail and rotor. The strenuous exercise of small grinding media can achieve truly effective grinding and dispersion of products, and according to actual situations, it can achieve sub-micron or nanometer range; the products stay in the grinding machine for a particularly short time with a certain flow rate through the outer layer and next ring inner grinding chamber, resulting in a very narrow distribution belt of product granules. Separation of grinding media The grinding media at the upper part of the grinding chamber is accelerated to the maximum peripheral speed through a guide plate. Thanks to a different density the grinding media is separated by centrifugal force and returns to the cylindrical vortex guide gap through the open slot in the rotor. As a new product flows into the grinding machine, the separated grinding media is once again sent to the rotor/stator’s outer grinding zone. Thus, the grinding media is formed through an internal closed ring of the inner and outer grinding chamber. Discharge Under the pressure of the feed pump, the products separated by the grinding media by means of centrifugation flow along the opposite direction of the centrifugal force, and then are discharged through the cylindrical protective screen set in the middle and the next discharge tube. It is very easy to take them down through the discharge tube and protective screen assembled by screw. DCD12 DCD100 DCD200 DCD400 DCD800 Main unit power (kw) 5.5 22~30 45~55 90~110 250 Tank capacity (L) 1.2 10 17 30 79 Maximun flow rate (L/h) 300 1200 3000 6000 12000 Please ask for more details from us freely; Machine Standard optional. Machine colors optional; Can Made to order. OEM | ||||

TESTING REPORT | YES. Always provide official test report before delivery. | ||||

OEM SERVICE | YES | ||||

CERTIFICATE | BV PRODUCT CERTIFICATE. CE | ||||

COLOR | WHITE, BLUE OR OPTIONAL | ||||

PRICE | |||||

| PAYMENT | T/T, L/C, | ||||

| PORT | SHANGHAI, SHENZHEN,GUANGZHOU | ||||

| MOQ | 800SETS/YEAR | ||||

| DELIVERY TIME | 15DAYS FOR STANDARD MACHINE | ||||

NOTE | |||||

We will offer you price referring to your detail request, so please kindly inform us of the material, viscosity, density, etc, and other requirements you prefer, and the special offer will be given. The pictures are above just for your reference. | |||||

ABOUT US | |||||

Sailing International Trading Co., Ltd. is the main supplier of coating machines in China. Sailing International Industry Group Limited is mainly engaged in manufacturing and global marketing of chemical machinery and auto parts. Our group has the following subsidiary companies, namely Nantong Sailing International Trading Co., Ltd., Shanghai Sanhuan Ink Equipment Engineering Technique Co., Ltd. and Sailing Auto Parts Factory. Our company has wide supply resources and enjoys good reputation both at home and abroad. We are one of the leading manufacturers and exporters of coating machines in China. Also, we act as an export agent for many key manufacturers of coating machines in China. Our company cooperates with multinational companies closely. We have a professional selling and after-sell services teams in Southeast Asia, Middle East Asia, and Eastern Europe. Our company provides professional and experienced export services for manufacturers in China. Our suppliers and distributors must have an opportunity to make a fair profit when they cooperate with us. We sincerely wish to cooperate with you. Please contact us at your convenience. Click here to get to know moreDETAILSof our Compatibility and Project Overseas http://www.sailing-intl.en.alibaba.com/custom_page_1.html (copy it in your address if the link can not open) | |||||

CONTACT | |||||

| ATTN | RICHARD SUN | ||||

| TEL | 86-0513-85109830 | 86-0513-85109691 | 86-0513-85518153 | 86-0513-55013135 | |

EXTENSION NO. | MARKET | ASIA: 104, 105 EURO&AFRICA:118,119 AMERICA: 102 OTHERS: 101 | |||

TECHNIC& AFTERSALE | 107 | ||||

| FAX | 86-85109939 | ||||

| EMAL | SAILING at SAILING-INTL.COM | ||||

| WEBSITE | WWW.SAILING-INTL.COM | ||||

WWW.CHINACOATINGMACHINE.CN | |||||

Your inquiry will be answered within 24 hours. Wishing to be your long-term partner, please feel free to contact us. We will do our best for you. | |||||

| Packaging Detail:International sea freight package. |

| Delivery Detail:60 days |