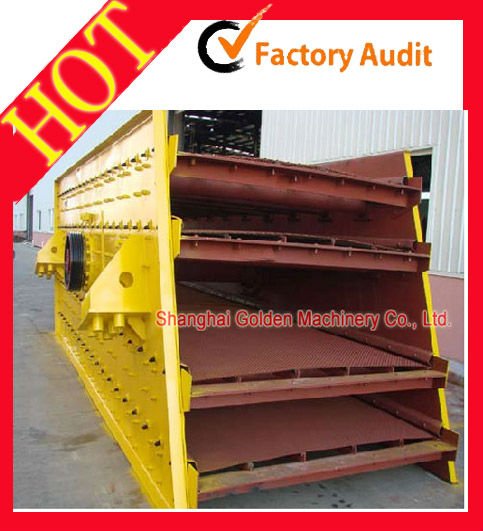

high efficient, high quality, not expensive vibrate sieve

| Condition:New | Type:Circular | Application:Food Processing | Place of Origin:Shanghai China (Mainland) |

| Brand Name:golden | Model Number:3YA2460 | Screen layers:3 | Mesh size(mm):3-100 |

| Screen size(mm):2400x6000 | Max feed size(mm):400 | Processing power(t/h):150-700 | Vibrating frequency(Hz):730 |

| Double amplitude(mm):6-8 | Motor power(kw):37 | Weight(t):13.2 | Overall dimensions(LxWxH):7130x41200x1930 |

The vibrating sieve are mainly used in coal dressing, metallurgy, mine, power station, water conservancy

project, building industry, light industry and chemical industry etc They are efficient screening machines for

the classification of bulk material such as coal, minerals, coke etc There are more than ten specifications

for YA series, of which the heavy duty type is for the classification of large size materials, while the Light

duty type is for the middle and small size materials.

vibrate sieve Features;

1)Simple and dependable Eccentric type system.

2)High screening capacity.

3)High durability.

4)No transmission of screen panels.

5)Ready changing of screen plates.

6)Rigid and vibrating resistance screen body.

Application of vibrating screen;

Vibrating screens work on circular motion. The vibrating screens are mainly used in coal dressing,metallurgy, mine, power station, water conservancy project, building industry, light industry and chemical industry etc They are efficient screening machines for the classification of bulk material such as coal, minerals, coke etc

high efficient, high quality, multi-layers not expensive vibrating sieve

Working Principle of vibrating sieves

Circular vibrating screen is single-axis circular-movement inertial vibrating screen, the working of circular vibrating screen depends on inertial motor and inertial strength produced by eccentric plate, because of the vibration of screen box, the materials are threw out, so that materials of certain size go through the screen mesh, and the screening aim is realized. Since the magnetic exciter is installed on the gravity center of screen box, the two long elliptical axis form a shape like a Chinese character, and the upper of long elliptical axis in inlet end is in the same direction with the outlet, which favors the spread of materials which is in the screen box. However, the upper of long elliptical axis in outlet end is opposite to the direction of the outlet, which can reduce the movement speed of materials, and help the difficult-screened materials go through the screen mesh. What’s more, the effective area of screen is increased because of the elliptical screen surface; as a result, the processing capacity is promoted.

vibrating sieve Technical parameters

Shanghai Golden machine service commitment

1.Pre-sale servicesof vibrating sieve

1) Selecting equipment type;

2) Designing and fabricating the products in accordance with the special requirements of the clients;

3) Training technical personnel for our clients;

4) Providing construction and technology consultations or working out proper construction schemes for those new, special or difficult projects.

2.Services provided during the sale

Respect our clients; present the clients with ease, relaxation and a surprise; devote ourselves to improve the total value of our clients.

1) Checking products acceptance ahead of delivery;

2) Introducing the Golden service system to our clients.

3. After-sale services of vibrating sieve

Improve the added value of our products, and let the clients free from the using troubles:

1) Assisting the clients preparing for the first construction scheme;

2) Installing and testing the equipments;

3) Training the first-line operators on site;

| Packaging Detail:standard container or according to the requirement of customers |

| Delivery Detail:20 days after receipt of the deposit |