High Efficiency grinding cement mill

| Condition:New | Type:Ball Mill | Motor Type:AC Motor | Power(W):According to customer requirements |

| Capacity(t/h):1.4-85TPH | Place of Origin:Henan China (Mainland) | Brand Name:ZK (BM) | Model Number:Pls refer to list below |

| Dimension(L*W*H):According to model | Weight:According to model | Certification:ISO9001 : 14000,ISO9001:14000 | Warranty:18 months |

| After-sales Service Provided:Engineers available to service machinery overseas | Feeding Size:25mm | Output Size:0.074-0.4mm | Drum Size:1.2m-4.2m |

| Power:210kw | Speed:21.6r/min | Iinstallation:under our engineer's guide | After sale service:for the whole using life |

| Name:cement mill |

High Efficiency grinding cement mill

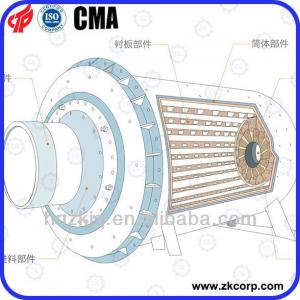

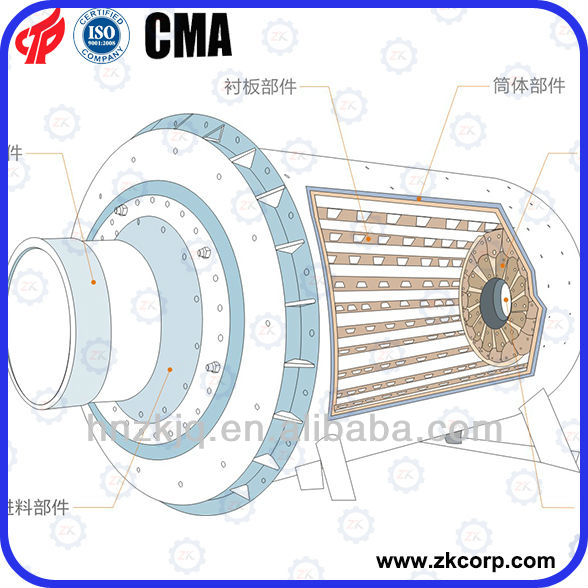

1.Grinding cement mill

Cement millhas a strong adaptability of materials to production,broken rate large,easy to speed grinding fineness of the product and so on.Ball mill of cement production is capable of dry production can also be wet,you can simultaneously grinding and drying operations.

2.Application:

Cement millis mainly used in grinding of cement finished products and materials,also to the metallurgical,chemical,electricity and other industrial and mining enterprises and other grinding various ore materials Grindability.Grinding can be used to open streams,but also to the composition and the separator flow grinding circle.Cement mill has a strong adaptability of materials to production,broken rate large,easy to speed grinding fineness of the product and so on.Ball mill of cement production is capable of dry production can also be wet,you can simultaneously grinding and drying operations.

3.Features:

1) is an efficient tool for grinding many materials into fine powder.

2) The cement mill is used to grind many kinds of mine and other materials, or to select the mine

3) cement mill is widely used in building material, and chemical industry.

4) There are two ways of grinding: the dry way and the wet way.

4.Technical parameters of cementMill

| Output t/h) | Rev (r/min) | Grinding Body (t) | Electricmotor | Reducer | |||

| Model | Power (kw) | Model | Ratio of Speed | ||||

| φ1.83×7 | material22 | 24.5 | 20 | JR138-8 | 245 | ZD60-9 | 4.5 |

| φ2.2×75 | material22 | 21.4 | 31 | JR158-8 | 380 | ZD70-9 | 5 |

| φ2.2×11 | material22-26 | 21.4 | 49 | JR1512-8 | 630 | ZDH80-4 | 4.5 |

| φ2.2×12 | material26-30 | 21 | 58 | YR630-8 | 630 | JS-90 | 35.2 |

| φ2.4×7.5 | material21-23 | 20.4 | 28 | JR158-8 | 380 | NZD450-5 | 5 |

| φ2.4×8 | material23-25 | 21.3 | 30.5 | YR630-8 | 500 | ZDH80 | 5 |

| φ2.4×(8+1.5) | material24-26 | 20.9 | 39 | YR630-8 | 500 | ZDH80A-5 | 5 |

| φ2.4×12 | material35-38 | 20 | 55 | YR800-8/1180 | 800 | ZD100A-41 | 6.43 |

| φ2.4×13 | material35-38 | 19.4 | 70 | YR800 | 800 | JDX800/MBY800 | 6.33 |

| φ2.6×13 | material50-55 | 19.5 | 82 | YR1000-8/1180 | 1000 | JDX800/MBY800 | 4.5 |

| φ2.8×5+3 | material36-47 | 18.6 | 32 | YR500-8 | 500 | ZDH80 | 4.5 |

| φ2.8×10 | material40-48 | 19.7 | 52 | YR800-8/1180 | 800 | D110A(1) | 37.5 |

| φ3×(9.25+1.75) | material45 | 17.8 | 70 | YR1000-8/1180 | 1000 | JDX800/MBY800 | 6.3 |

| φ3×11 | material45-48 | 18.7 | 50 | YR800-8/1180 | 800 | ZD100A | 6.43 |

| φ3×12 | material55-58 | 18 | 95 | YR1250-8/1430 | 1250 | JS110-A | 41.1 |

| φ3.2×7+D | material50 | 17.8 | 58 | YR1000-8/1180 | 1000 | JDX800/MBY800 | 4.5 |

| φ3.2×9 | material65 | 17.6 | 90 | YR1250-8/1180 | 1250 | JS110-A | 184.5 |

| φ3.2×10 | material55 | 17.6 | 65 | YR1000-8/1180 | 1000 | JS100 | 41.5 |

| φ3.4×(7.5+1.8) | material60 | 17.2 | 70 | YR1000-8/1430 | 1000 | JDX900/MBY900 | 6.3 |

| φ3.5×10m | material75 | 16.6 | 80 | YR1250-8/1430 | 1250 | JDX900/MBY900 | 6.3 |

| φ3.8×7.5 | material85 | 16.7 | 85 | YR1400-8/1430 | 1400 | JDX900/MBY900 | 7.1 |

| φ3.8×(7.5+1.5) | material75 | 16.7 | 85 | YRKK900-8 | 1400 | JDX900/MBY900 | 46.5 |

| φ4.6×(8.5+3.5) | material150 | 15 | 150 | YRKK900-8 | 2800 | JS140-A-F1 | 49.5 |

| φ4×10+3.5 | material110-130 | 16 | 150 | YRKK900-8 | 2500 | JS130-C | 46.5 |

5.Installation

| Packaging Detail:Standard packing for exported items for High Efficiency grinding cement mill. |

| Delivery Detail:Within 50 days |