high efficent good performance instant coffee production line

| Processing:Concentrator | Place of Origin:China (Mainland) | Brand Name:JY | Processing Types:Coffee |

| easy to operate:high efficent | good:high quality | delicious:good result |

| Coffee producyion lines |

Shanghai Junyu Internatianl Grouparethe expert manufacturer in Chinawho hassuccessfully supplied entire coffee processing plant, which consists of coffee bean transportation, weighing, and cleaning section, roasting section, bean breaking section. extraction section, evaporation and aroma treatment section, spray drying section, and packaging section.If it is required, we might also provide the system of utilities (steam, cooling water and compressed air etc), as well as design of the workshop.We have supplied Severalentire production lines till now,Customers that are interested, please contact us for further details. We can supply budget of the total investment, area occupied, utilies consumption based on each ton, and other relative information for customers to make decision |

Instant coffee, also calledsoluble coffeeandcoffee powder, is a beverage derived from brewed coffee beans. Instant coffee is commercially prepared by either freeze-drying or spray drying, after which it can be rehydrated. Instant coffee in a concentrated liquid form is also available

Advantages of instant coffee include speed of preparation (instant coffee dissolves instantly in hot water), lower shipping weight and volume than beans or ground coffee (to prepare the same amount of beverage), and long shelf life—though instant coffee can also spoil if not kept dry.

History

Instant or soluble coffee was invented and patented in 1889 by Mr David Strang of Invercargill, New Zealand under patent number 3518.[2]It was sold under the trading name Strang's Coffee[3]citing the patented "Dry Hot-Air" process. The invention was previously attributed to Satori Kato, a Japanese scientist working in Chicago in 1901. Kato introduced the powdered substance in Buffalo, New York, at the Pan-American Exposition.[4]George Constant Louis Washington developed his own instant coffee process shortly thereafter, and first marketed it commercially (1910). The Nescafé brand, which introduced a more advanced coffee refining process, was launched in 1938.

High-vacuum freeze-dried coffee was developed shortly after World War II, as an indirect result of wartime research into other areas. The National Research Corp. was formed in Massachusetts as a process-development company employing high-vacuum technology. It developed high-vacuum processes to produce penicillin, blood plasma and streptomycin for US military use. As the war ended, NRC looked to adapt its processes for peacetime uses. It formedFlorida Foods Corp.to produce concentrated orange juice powder, and originally sold its product to the United States Army. That company later changed its name toMinute Maid.

Use

Instant coffee is available in powder or granulated form contained in glass jars, sachets or tins. The user controls the strength of the resulting product, by adding more or less powder to the water, ranging from thin "coffee water" to very strong and almost syrupy coffee. A novel way is to use coffee bags, similar to tea bags.

Instant coffee is also convenient for preparingiced coffeelike the Greek frappé, which is popular in warmer climates and hot seasons.

In some countries such as Portugal, Spain and India, instant coffee is commonly mixed with hot milk instead of boiling water.

Production

As with regular coffee, the green coffee bean itself is first roasted to bring out flavour and aroma. Rotating cylinders containing the green beans and hot combustion gases are used in most roasting plants. When the bean temperature reaches 165 °C the roasting begins, accompanied by a popping sound similar to that produced by popcorn. These batch cylinders take about 8–15 minutes to complete roasting with about 25–75% efficiency. Coffee roasting using a fluidized bed only takes from thirty seconds to four minutes, and it operates at lower temperatures which allows greater retention of the coffee bean aroma and flavor.

The beans are then ground finely. Grinding reduces the beans to 0.5–1.1-millimetre (0.020–0.043 in) pieces in order to allow the coffee to be put in solution with water for the drying stage. Sets of scored rollers designed to crush rather than cut the bean are used.

Once roasted and ground, the coffee is dissolved in water. This stage is called extraction. Water is added in 5–10 percolation columns at temperatures of 155 to 180 °C; this concentrates the coffee solution to about 15–30% coffee by mass. This may be further concentrated before the drying process begins by either vacuum evaporation or freeze concentration.

Freeze drying

Production freeze-drier.

The basic principle of freeze drying is the removal of water by sublimation.

Since the mass production of instant coffee began in post-WWII America, freeze-drying has grown in popularity to become a common method. Although it is sometimes more expensive, it generally results in a higher-quality product.

- Agglomerated wet coffee granules are rapidly frozen (slow freezing leads to large ice crystals and a porous product and can also affect the colour of the coffee granules).

- Frozen coffee is placed in the drying chamber, often on metal trays.

- A vacuum is created within the chamber. The strength of the vacuum is critical in the speed of the drying and therefore the quality of the product. Care must be taken to produce a vacuum of suitable strength.

- The drying chamber is warmed, most commonly by radiation but conduction is used in some plants and convection has been proposed in some small pilot plants. A possible problem with convection is uneven drying rates within the chamber, which would give an inferior product.

- Condensation - the previously frozen water in the coffee granules expands to ten times its previous volume. The removal of this water vapor from the chamber is vitally important, making the condenser the most critical and expensive component in a freeze-drying plant.

- The freeze-dried granules are removed from the chamber and packaged.

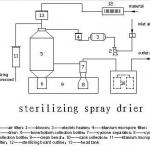

Spray drying

Laboratory-scale spray dryer.

A=Solution or suspension to be dried in, B=Atomization gas in, 1= Drying gas in, 2=Heating of drying gas, 3=Spraying of solution or suspension, 4=Drying chamber, 5=Part between drying chamber and cyclone, 6=Cyclone, 7=Drying gas is taken away, 8=Collection vessel of product, arrows mean that this is co-current lab-spraydryer

Spray drying is preferred to freeze drying in some cases because of its economy, short drying time, usefulness when dealing with such a heat-sensitive product, and the fine, rounded particles it produces.

Spray drying produces spherical particles about 300 micrometres (0.012 in) size with a density of 0.22 g/cm³ (ref 2). To achieve this, nozzle atomization is used. Various ways of nozzle atomization can be used each having its own advantages and disadvantages. High speed rotating wheels operating at speeds of about 20,000 rpm are able to process up to 60,000 pounds (27 tonnes) of solution per hour (ref 3). The use of spray wheels requires that the drying towers have a wide radius to avoid the atomized droplets collecting onto the drying chamber walls.

- Completed in 5–30 seconds (dependent on factors such as heat, size of particle, and diameter of chamber).

- Moisture content change: IN = 75-85% OUT = 3-3.5%

- Air temperature: IN = 270 °C OUT = 110 °C

One drawback with spray drying is that the particles it produces are too fine to be used effectively by the consumer; they must first be either steam-fused in towers similar to spray dryers or by belt agglomeration to produce particles of suitable size.

| Packaging Detail:wooden box |

| Delivery Detail:ASAP |