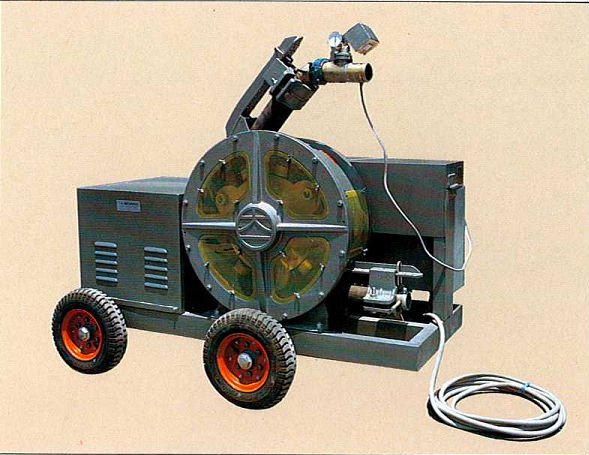

High discharge Mortar pump Made in Japan

| Condition:New | Place of Origin:Japan | Brand Name:Nagoya Katan | Model Number:Mortar pump |

A high quality Japanese mortar pump

Small, lightweight model / extremely high performance

Discharge capacity that other companies cannot match Max volume 10m3/H

♣Automatic control by pressure switch ♣

When the pressure exceeds 20kg an alarm will go off, warning about

blockage caused by material imperfections or bending of the hose.

Furthermore, when the pressure exceeds 30kg the power supply is

automatically cut to prevent damage to the hose or pumping tube, or

pump failure due to material blockage.

♣ A cone-shaped hopper ♣

A cone-shaped hopper improves

the evenness of the materials and reduces the clumping together of

materials inside the hopper. It also eliminates the inconvenience of

mortars sticking to the corners, which can be seen in existing -

square -hoppers, and simplifies the post-operation cleaning process.

♣ Economical efficiency of a pumping tube ♣

Tubes generally last longer the larger the drum is, but thanks to our

squeeze-type pump with a slanted discharge opening, available on all

models (with the exception of the portable pump),

for drums of the

same diameter our devices have an effect comparable to that of a much

larger drum. This also protects against unreasonable bending of the

tube. As the tubes have a large inner diameter (65φ, 50φ) and thick

walls, they are also amazingly durable.

♣Remote controls♣

Remote controls for the D-65,

D-50 and D-35MF are standard equipment, multi-use 100V/200V. D-15EY

(when using a motor) and D-45 portable pumps can be ordered.

.................................................

♦D65 type

♦D50 type

♦D45 type

♦D35 MF type

♦D15EY type

♦100V/200V Combination

♦Portable pump

♦new Portable pump

.................................................

(Company Overview)

| Company Name | Nagoya Katan, Inc. |

| President & CEO | Kiyohiko Yamada |

| Location | 4-5 Kyuban-cho, Minato-ku, Nagoya-shi |

| Phone No. | 052-651-5491 |

| Fax No | 052-651-5499 |

| PropertyLand | 1,085m ² Buildings 775m² |

| Capital | ¥70 million |

| Founded | January 1960 |

| No. of Employees | 10 |

| Partner Factories | Regular cast iron and ductile cast iron – 8 factories Aluminum cast products – 2 factories Brass and bronze cast products – 2 factories Stainless cast products – 2 factories 12 machining plants Total: 18 NC lathes, 24 machining centers |

(History)

| 1960 | Nagoya Katan Factory Office, Co. Ltd. was founded in Nagoya, and the factory began operations |

| 1970 | Reorganized as Nagoya Katan Factory Office, Inc. |

| 1971 | Operations began in the Kabuchi factory (Gifu prefecture) |

| 1972 | The factory in Nagoya closed and was converted to a distribution warehouse |

| 1988 | Imports of cast products from Taiwan began |

| 1990 | More sales offices and warehouses were built in Nagoya, coinciding with the firm’s business expansion A related firm, Sankou Industries, Inc. was founded |

| 1992 | Imports of cast products from China began |

| 1993 | The Kabuchi factory (Gifu prefecture) ceased operations |

| 1994 | The company name was changed to Nagoya Katan, Inc. |

| 1999 | An independent affiliated factory was founded in Dalian, China |

| 2010 | More sales offices were built in Nagoya, coinciding with the firms’ business expansion and an increased number of personnel |

(About the Dalian factory)

The company established a factory in Dalian, China in 1999 in response to consumer demand for quality products while controlling costs, which had increased in recent years.

Not only does production take place at the Dalian factory, but products that have been manufactured and processed at our partner factories in China undergo inspection at the Dalian factory too.

(High Quality at Low Cost – Carrying out our promise through our inspection process)

Our staff at the Dalian factory undergo regularly scheduled training in Japan. In addition to covering the obvious technical matters, this training also gives our staff an understanding of the Japanese language, business customs, and mentality of Japanese people. In addition, Japanese staff members visit China every month in shifts. In order to respond quickly to problems that arise, we are introducing a teleconferencing system and are making efforts to maintain and improve product quality.

The idea that “products made in China are cheap and of poor quality” is already a thing of the past.

| Packaging Detail:It will be shipped in a wooden box.Other packaging options are available, please feel free to contact us. |

| Delivery Detail:We will send it out a few days after the deposit |