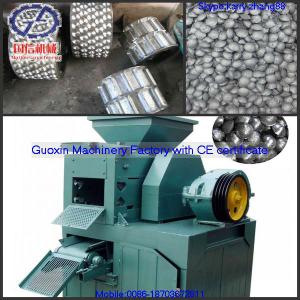

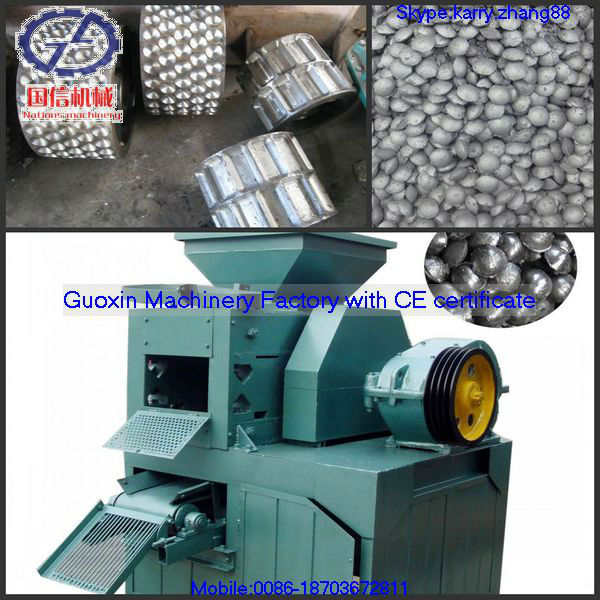

High density coal briquette making machine in good quality

| Type:Briquette Machines | Condition:New,100% new | Production Capacity:97% | Motor Type:AC Motor |

| Power(W):5500-110000 | Place of Origin:Henan China (Mainland) | Brand Name:GUOXIN | Model Number:Any type as required,HJXM-360 HJXM-430 HJXM-520 HJXM |

| Dimension(L*W*H):3000X1500X2600 | Certification:ISO | Warranty:One year | After-sales Service Provided:Overseas service center available |

| Color:Any color as required | Shipping:By sea | Hardness of finished briquette:Droping from 2 meters high, 85% will | Aplication:Produce briquette from different shape |

| Remind:We supply the briquette production | Service:Using whole working life | Quick wear parts:We supply | Quality:Export standard with reliable structure |

General Introduction of Coal Briquette Making Machine

The purpose of coal briquette machine is to reduce dust, control volume-weight, improve transport characters and recycle materials. coal briquette machine has advanced technology and reliable quality. It is suitable for large, medium and small factory to build large scale production line. It is applied to industrial gas making, boiler, cold briquetting process, fired briquette, civilian use coal briquette, metallurgy, refractory materials, medicals and other fields.

The coal briquette making machine using area:

The coal briquette machine is mainly used to suppress difficult molding powder materials, characterized by forming pressure, the host rpm adjustable, with a spiral Feeding Device. it can be used to suppresscoal, iron, coke, aluminum powder, iron oxide skin, slag, gypsum, tailings, sludge, kaolin, activated carbon, coke powder and other ferrous powder, non-ferrous powder. It is widely used inrefractory, power plants, metallurgy, chemical, energy, heating industry. Finish products with the character of energy saving, easy to transport, increase of wastes Utilization, with good economic and social benefits.

Mainly parameter about coal briquette making machine:

| Type | Dia of roll (mm) | Production Capacity(T/H) | Power(KW) | Overall size (mm) | Reduction type | Weight (T) |

| 360 | Φ360 | 4 | 7.5 | 1460×1460×2040 | 400 | 1.4 |

| 400 | Φ400 | 6 | 11 | 2450×1600×2230 | 500 | 2 |

| 500 | Φ500 | 10 | 22 | 2650×1750×2300 | 500 | 2.6 |

| 650 | Φ650 | 14 | 37 | 2880×2220×2500 | 650 | 5.5 |

| 750 | Φ756 | 17 | 45 | 3015×2441×2166 | 750 | 7 |

| 800 | Φ804 | 20 | 55 | 3200×2550×2220 | 850 | 8 |

| 1000 | Φ1000 | 30 | 90 | 2600×3000×2500 | 1300 | 25 |

Advantage about coal briquette making machien:

1. Coal briquette making machine have high volume of production and forming

2. Coal briquette making machine have various kinds of standard ( depend on the size of the pellte and the material you use)

3. Coal briquette making machine in low energy cost

4. Coal briquette making machine in high ratio of forming

5. Coal briquette making machine with competetive price

6. Coal briquette making machine have thoughtful after service

Working principle of Coal briquette making machine:

This series of coal briquette making machine will pass the power on to the two pressure roller through the reducer.The two sides and roll rotation, in both the rotating roll,Natural materials to enter the ball roll mode, with the roll rotation, material pressure on a small become larger.

When the material to the coal briquette machine two rollers rotating line contact point, the pressure of materials has reached the peak.

Tremendous pressure in the role of line, the materials become a finished product from the powder press.

Main pictures about the coal briquette making machine:

| Packaging Detail:Standard container with 40GP or 40HQ, machine in wooden box |

| Delivery Detail:15 working days after receive advanced payment |