High Corrosion Resistance Stainless Steel Plates Nickel Brazed Plate Heat Exchangers for Ammonia System NL20 Series

| Condition:New | Place of Origin:Jiangsu China (Mainland) | Brand Name:Baode | Model Number:NL 20 |

| Structure:Plate Heat Exchanger | Liquid Flow Rate:8 M3/h | Maximum Working Pressure:20 bar | Certification:CE,ROHS,UL,ISO WRAS CCS |

| Warranty:1 year | Plate Heat Exchanger type:Nickel Brazed Plate Heat Exchanger | Main application:Ammonia system | Plate Material:Stainless steel AISI316/304 |

| Brazing material:Nickel |

High Corrosion Resistance Stainless Steel Plates Nickel Brazed Plate Heat Exchangers for Ammonia system NL20 series

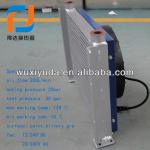

| Model | NL20 | ||

| Width, A [mm] | 76 | ||

| Height, B [mm] | 310 | ||

| Length, E [mm] | 9+2.3n | ||

| Horizontal port distance, C [mm] | 42 | ||

| Vertical port distance, D [mm] | 282 | ||

| Max pressure [Mpa] | 2 | ||

| Max flowrate [M3/h] | 8 | ||

| Weight [kg] | 1.0+0.08n |

General information

NL series is a plate heat exchanger made of stainless steel and Nickel. Nickel heat exchangers are well suited

in applications which put high demand on cleanliness, applications where ammonia is used.

Its high resistance to corrosion makes it both hygienic and environmental friendly. It is extremely compact

compared to its capacity to withstand great strains in demanding heat transfer applications.

Working principles

The heating surface consists of thin corrugated metal plates stacked on top of each other. Channels are formed

between the plates and corner ports are arranged so that the two media flow through alternate channels, always

in counter current flow. The media are kept in the unit by a bonded seal around the edge of the plates. The contact

points of the plates are also bonded to withstand the pressure of the media handled.

Standard design

The plate pack is covered by cover plates. Connections are located in the front or rear cover plate. The channel plates

are corrugated to improve heat transfer design.

Particulars required for quotation

To enable Alfa Laval's representative to make a specific quotation, enquiries should be accompanied by the following

particulars:

– flow rates or heat load required

– temperature program

– physical properties of liquids in question

– desired working pressure

– maximum permitted pressure drop

Applications Within refrigeration:

- Oil cooler

- Condenser

- Evaporator

- Economizer

- Desuperheater

- Absorption systems

Other main applications:

- Domestic hot water heater

- Process cooling

- Hydraulic oil cooling

- Laser cooling

- Hygienic/sanitary

- Water/water cooling & heating

Short delivery time.

High quality

Reasonable price

Customer made

Know-how design and customer support

| Width | Height | Horizontal port distance | Vertical port distance | Thickness mm | Max Plates | Max flowrate (M3/h) | Weight (kg) | Heat exchange area (m2) | Volume L |

| 76 | 310 | 42 | 282 | 9+2.3N | 100 | 8 | 1.0+0.08N | 0.02 (N-2) | 0.018 (N-2) |

| Type | Width | Length | Horizon hole | Vertical Hole | Height | Weight |

| NL14 | 76 | 206 | 42 | 172 | 10+2.3N | 0.7+0.06N |

| NL20 | 76 | 310 | 42 | 280 | 10+2.3N | 1.0+0.08N |

| NL26 | 111 | 310 | 50 | 250 | 10+2.35N | 1.3+0.13N |

| NL50 | 111 | 525 | 50 | 466 | 10+2.5N | 2.0+0.21N |

| NL95 | 191 | 616 | 92 | 519 | 11+2.35N | 7.8+0.44N |

| Packaging Detail:Plywood case |

| Delivery Detail:30 days |