GZ series Excellent and Tiny Electromagnetic feeder for Chemical Machinery

| Condition:New | Place of Origin:Henan China (Mainland) | Brand Name:DZ | Model Number:GZ |

| Weight:77-1500kg | Transmission Length:0.05 km | Certification:BV&CE certificate | After-sales Service Provided:Engineers available to service machinery overseas |

| Driver:Electromagnetism | Structure:Tiny | Feeder:Evenly | Volume:Small |

| Power consumption:Low | Application:Chemical Machinery | Voltage:220V | Double amplitude:1.5-2mm |

| Capacity:0.5-6t/h | Control:PLC |

GZ series Excellent and Tiny Electromagnetic feeder for Chemical Machinery

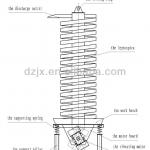

Brief Introduction-Tiny Electromagnetic Feeder

Tube electromagnetic vibrating feeder can feed bulk or granular materials from the storage bin to the receiving device evenly and continuously. It can realize even feeding for crushers in sand stone production line and make rough screening for materials.

Working Principle-Tiny Electromagnetic Feeder

When the power is on, the electric current passes the excitation coils, which creates a magnetic field. The magnetic force changes into vibrating force, which forces the transmission trough body to make simple harmonic vibration or similar to simple harmonic vibration in a certain direction. When the acceleration of its vibration achieves some certain value, the materials will make continuous and small throws or slides along the transmission direction in the transmission trough body, which causes the forward motion and transmission of the materials.

Features-Tiny Electromagnetic Feeder

•In the production process, it delivers the anti-block materials, granular, powdery materials from the storage silo or funnel to the affected device quantitatively, uniformly and continuously.

•Electric control uses half-wave silicon-controlled rectifier circuit. It can adjust to the charge level, and it can be used for automatic control of the production process, so that realize production automation.

• It has no rotating parts, no need to lubrication, simple structure, easy to maintenance.

• Material is micro-throwing movement, and silo has small wear.

• It uses the silo which is made of alloy steel plate. It’s applicable to transport heat, wear and corrosive materials, etc

Advantages-Tiny Electromagnetic Feeder

1. Exclusive vibrating technology.

2. Small size and light in weight.

3. Simple structure, easy to install and use, low maintenance cost.

4. High efficiency and feeding capacity.

5. Good operational reliability and easy adjustment.

6. Electromagnetic vibrating feeder uses up less electric energy.

Model Structure

| Model | B | B1 | B2 | B3 | B4 | L | L1 | L2 | L3 | H | H1 | H2 | H3 |

| GZ1 | 200 | 280 | 340 | 296 | 376 | 600 | 209 | 550 | 910 | 100 | 350 | 360 | 485 |

| GZ2 | 300 | 388 | 456 | 400 | 506 | 800 | 310 | 660 | 1175 | 120 | 430 | 450 | 600 |

| GZ3 | 400 | 496 | 518 | 452 | 574 | 900 | 311 | 790 | 1325 | 150 | 480 | 520 | 675 |

| GZ4 | 500 | 620 | 682 | 581 | 762 | 1100 | 413 | 965 | 1615 | 200 | 550 | 645 | 814 |

| GZ5 | 700 | 850 | 761 | 650 | 840 | 1200 | 465 | 1050 | 1815 | 250 | 647 | 765 | 980 |

| Packaging Detail:Packaging details: Free fumigation plywood case |

| Delivery Detail:Within 15 working days after receiving the deposit |