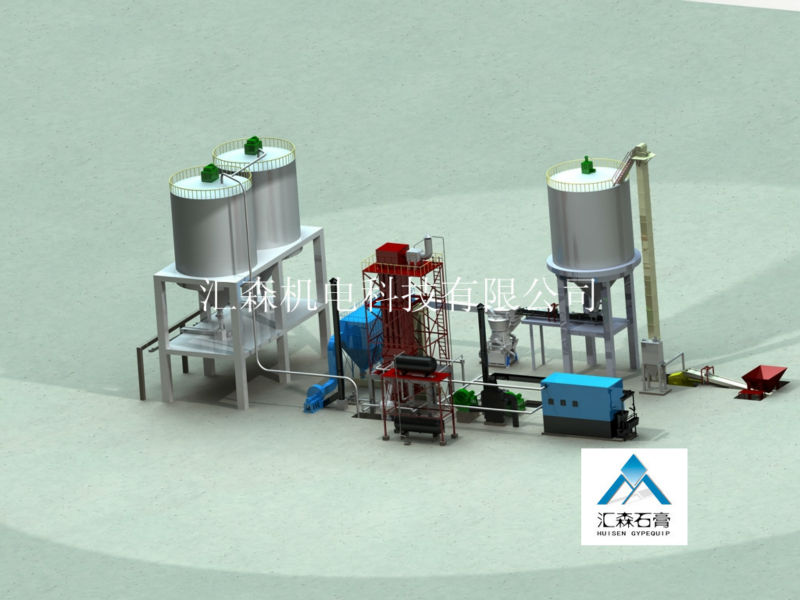

Gypsum plaster powder production line

| Condition:New | Application:Construction material | Automatic Grade:Automatic | Production Capacity:98% |

| Place of Origin:SHN, Shandong, China (Mainland) China (Mainland) | Brand Name:Huisen | Model Number:HS130228 | Voltage:220V/380V |

| Power(W):230kw | Weight:150tons | Features:saving energy | Certification:IS09001 |

| Warranty:12 months | After-sales Service Provided:Engineers available to service machinery overseas | Capacity:30,000 t - 500,000 t | degree of automatic:Full-automatic |

| Calcination system:Boiling furnace | Type 1:Hot oil drying | Type 2:Hot air drying | Type 3:Heat exchanger drying |

| Cost:Lower | Evironmental:Friendly |

Gypsum powder production line

1.1Design Condition

1.1.1Environmental temperature: max. 50°C; Min. - 30°C.

1.1.2 Air related humidity: max. 95%; min. 15%.

1.1.3 Raw material: Natural gypsum ore

Note: If the gypsum ore does not meet the above requirements, please provide the oreanalysis report or samples for laboratory tests to determine whether it meets production requirements

1.1.6Production line capacity and parameter list:

1.1.7Fuel:Coal, Natural Gas, diesel oil, heavy oil, biofuels, electricity

1.1.8 Power supply

Low voltage: 380V Three phase

220V Two phase

Frequency: 50Hz

Please point it out if the power supply in the Buyer’s site does not meet the above requirements. The Seller shall consider differences in the design and equipment selection avoid equipment failure or inability to produce

1.1.9 Water supply

Pressure of water supply: ≥0.2Mpa

Water quality: be accordance with drinkable water standard

1.1.10Product design standard: Chinese National Standard GB/T9776-2008 “BUILDING GYPSUM”.

Note:1. Based on the gypsum grade≥80%

2. Please offer the gypsum sample to test if Buyer have special quality requirements

1.1.11Dust control:Discharge amount:≤50mg/m3,

Work post:≤10mg/m3

1.1.12Noise control:≤85dba ( 1 meter away from noise source)

1.1.13 Work time:

Crushing and packing section:300daysx8hours

Grinding and calcining section:300days x 24hours

2.Process Description

The gypsum rocks with the dimeter less than 300mm are pushed into Chain Conveyor by forklift, then they are sent to Crusher by Chain Conveyor, being crushed into small grain less than 25mm and then being stored and metered by Belt Scale then being sent into Vertical Mill to mill. After being milled, the qualified gypsum powder will be sent to Boiling Kiln to calcine; after being calcined, parts of the temperature of the qulified gypsum powder is 800-100°C after being cooled. Then the gypsum powder is sent to hemi-hydrate gypsum storehouse by air current conveying system.

3. Description of Electric Control System and Auto-control System

3.1 Control system of Gypsum Powder Production Line

We use DCS (Distributed Control System) because that powder control system is a process automatic system with dispersive control point, this system can be divided into 1 main station and 4 sub-station by the different zones, which are respectively in Main Control Room, Crusher, Calcinating, Mill, Boiling Kiln and Storehouse. Every part of this system in Central Control Room and at Site can control all control points and know producing circs, writing down control cics and giving an alarm. Gypsum Powder production line is a continuous process, if one part is in trouble, it will stop the whole line, so it is very important to find out malfunction in time.

3.2 Electric structure drawing

Control ways: There are 3 ways for the electric control system: CRT Automatic, CRT Manual & Site Control.

CRT Automatic: the site will operate according to the procedure requirements when the control condition for operation and process equipments all meet requirements, making orders by central control room.

CRT Manual: the workers operate process equirements separately and manually by the requiements of process, making orders by central control room. ( such as adjusting flux of Belt Scale, adjusting temperatures, etc.)

Site Control: to operate equipments on site.

3.3 Electric control equipments

3.3.1The general design is in conformity with GB Standard and IEC Standard.

3.3.2The control cabinet adopts NSM cabinet of CHNT, protection-resistance grade for cabinet body is IP55.

3.3.3Power pressure degree

Dynamical power supply:Three phase 380V AC 50Hz

Control power supply: Two phase 220V AC 50Hz

PLC I/O power supply: 24V DC

Transducer power pressure:24V DC

Please point it out if the power supply in the Buyer’s site does not meet the above requirements. The Seller shall consider differences in the design and equipment selection avoid equipment failure or inability to produce

3.3.4Main equipments

Upper Level Work Station:

Hardware

Host computer:2; Type: DELL

Core i5 3.2GHz/2G/512M/500G/8XDVD

Including:21",Resolution1920x1080,keyboard,mouse

Including CRT: 21", resolving power: 1920 x1080, keyboard and mouse.

Control Station:

PLC: SIEMENS or MITSUBISHI

Transducer: SIEMENS or MITSUBISHI

Cabinet body: CHNT

Low-voltage electric CHNT

| Packaging Detail:It needs about 8-10 containers(40 feet) to delivery the machine |

| Delivery Detail:Within 2 months after receiving the down payment |