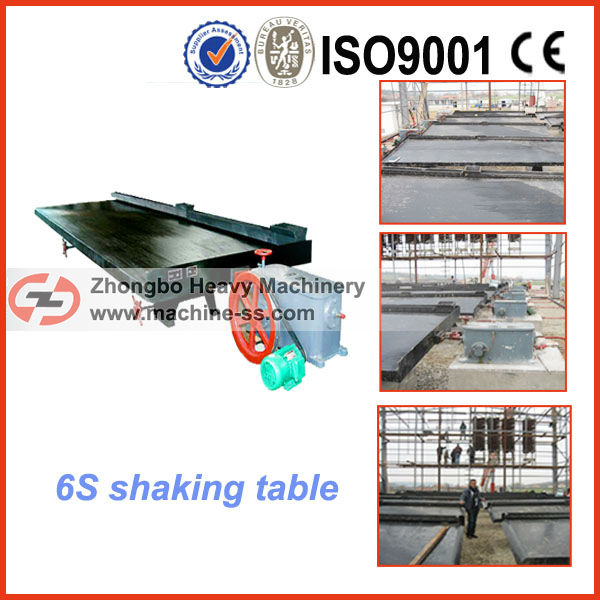

gravity mineral separating shaking table

| Place of Origin:JIA,shanghai, china China (Mainland) | Brand Name:Zhongbo | Model Number:6-S | Condition:New |

| After-sales Service Provided:Engineers available to service machinery overseas | type:gravity concentrator,Separator | delivery:30 days | color:as requested |

| packing:export standard | Application:Ore |

gravity mineral separating shaking table

I. Application of Mengfan gravity mineral separating shaking table.

Shaking bed, which is also called table concentrator, is a mine selecting machine for fine materials working by gravity. It is widely used in selection of Tin, tungsten, gold, silver, lead, zinc, tantalum, niobium, iron, manganese, ferrotitanium and coal.

II. operating principle of Mengfan gravity mineral separating shaking table.

The bedis composed of a deck, in somewhat of a rectangular shape, covered with riffles (raised bars running perpendicular to the feed side of the table), mounted in a near flat position, on a supporting frame that allows the table to slide along the long axis of the table.

On a table, with particles of mixed densities, layers of material form, a particle in suspension will be subjected to a greater force the nearer it is to the surface of the water, and will cause it to tumble over those at greater distances from the surface. The combination of the particles tumbling and sliding, the flowing stream with differing velocities, will cause the bed of solids to dilate, and will allow high SG particles to find their way down through the bed of light SG particles, and eventually the low SG particles will work their way to the top, where they will be carried along by the swifter flowing water. In all gravity separations, a difference in specific gravity of the materials needs to be significant, at 1 or greater. I.e., a 2.2 SG material will usually separate from a 3.2 SG material.

III. technical parameter of mengfan gravity mineral separating shaking table

Name | Unit | Grit shaking bed | Fine sand shaking bed | Sludge shaking bed | |

Dimensions | Length | MM | 4450 | 4450 | 4450 |

| Driving part width | MM | 1855 | 1855 | 1855 | |

| Concentrate part width | MM | 1546 | 1546 | 1546 | |

Max. feeding size | MM | 2 | 0.5 | 0.15 | |

Feeding amount | T/d | 30-60 | 10-20 | 15-25 | |

Feeding thickness | % | 25-30 | 20-25 | 15-25 | |

Journey | Mm | 16-22 | 11-16 | 8-16 | |

Frequency | F | 15-48 | 48-53 | 50-57 | |

Water quantity | T/d | 80-150 | 30-60 | 10-17 | |

Horizontal obliquity | Degree | 2.5-4.5 | 1.5-3.5 | 1-2 | |

Portrait obliquity | % | 1.4 | 0.92 | ----- | |

Table board corner | Degree | 32-42 | 40 | 42 | |

Concentrating square | ---- | 7.6 | 7.6 | 7.6 | |

Table board length ratio | ---- | 2.6 | 2.6 | 2.6 | |

Motor power | KW | 1.1 | 1.1 | 1.1 | |

| Packaging Detail:export standard |

| Delivery Detail:30 days |