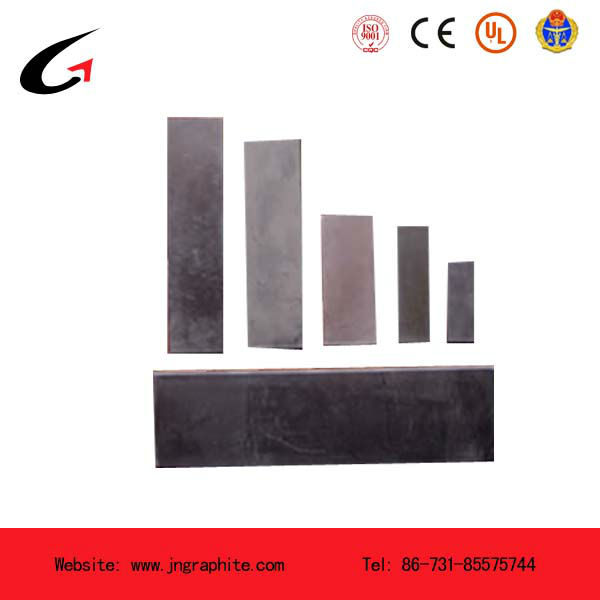

Graphite vanes for dry-running and fresh oil-lubricated rotary vane compressors and vacuum pumps.

| Place of Origin:Hunan China (Mainland) | Brand Name:Jiangnan | Model Number:JN-JX-007 | color:black |

| density:1.78--1.85g/cm3 | porosity:12-18% | compressive strength:45-65Mpa | rupture strength:15-18Mpa |

| modulus of elasticity:9-10Gpa | resistivity:9-11μΩ.m | shore hardness:45-50 |

When you talk about CARBON and GRAPHITE, Please remember JIANGNAN!

Application:

Size:

As per the clients requirements.

Product Characteristics:

Specialty graphite

Specialty graphites are materials whose matrix consists of carbon graphite components.They feature good dry-running properties when used in tribological systems. Their graphite lattice structure comprises carbon atoms arranged in planar hexagonal rings with an interlayer dis-tance of 0.335 nm. Owing to the weakness of the van der Waals attractive forces, these planes can be quite easily displaced relative to one another. The physical parameters of carbon materials are governed by the production processes illustrated on page 4. The shaping process depends mainly on the output number to be manufactured: Large batches are pressed to size or injection-molded (depending on the tool dimensions), whereas small batches are ma -chined from larger semifinished products.

Oxidation resistance

Graphite can be used in an oxidizing atmo-sphere at up to approx. 500 °C. The application limits of impregnated variants depend on the type of impregnation involved. For specific applica -tions, we supply graphite materials with oxidation inhibitors, which allow the oxidation resistance to be raised to temperatures of 600 °C.

Food safety

Many of our machine element brands have been approved for use in the food and drinking water sector.

Chemical resistance

Carbon products are insoluble and do not melt. They are resistant to virtually all media such as organic solvents, anti-freezing agents, refriger -ants and technical resins. Carbon is also highly resistant to organic media such as alkalis and most acids. The corrosion resistance of synthetic resin- or metal-impregnated carbon components is governed by the pH value. As a general rule, synthetic resin-impregnated carbon materials are resistant to acid media, whereas metal-impregnat-ed variants can withstand alkaline attack

Other properties

• High mechanical strength

• Good sliding properties

• High thermal stability

• High thermal shock resistance

• Low wettability

• High corrosion resistance

• High thermal conductivity

• Good electrical conductivity

Manufacture of Carbon and Graphite

Performance:

Carbon and graphite

The production stages for carbon materials are comparable to those for ceramics. Products baked at approx. 1,000 °C are known as hard carbon, hard burned carbon or carbon graphite. The product yielded by thermal treatment above 2,500 °C is called electrographite.

Production Sites and Customer Service

Business Line Graphite Specialties

The three pillars of our production system are high quality, adherence to deadlines and our highly motivated and competent workforce. We demonstrate this claim in three continents (Europe, the Americas and Asia) to get maximum benefit from both cost-effectiveness and close customer contact.

Our services

• Close customer contact through a global marketing network covering more than 90 countries

• Professional technical and individual advice provided at customers‘ own sites

• Detailed design proposals to solve customer-specific problems

• Application-oriented training in key applications and special literature

• Extensively equipped laboratories for analyses

• Reliable and flexible delivery service

We are Jiangnan – The Carbon Company, one of the worldwide leading manufacturers of carbon-based products.

We have an in-depth materials, production, applications and engineering expertise, a comprehensive graphite and carbon fiber-based product portfolio, and an integrated value chain from carbon fibers to composites. We operate close to our customers through a global sales network and state-of-the-art production sites in Europe, North America and Asia. With this Broad Base, we offer Best Solutions to our customers .

We constantly aim to improve our products and services to meet our customers‘ specific requirements. Our company are state-of-the-art tools for bringing continuous improvement to all areas, including our processes, engineering know-how, product development and innovation, as well as the expertise of our workforce. We keep close contact with our customers, suppliers and logistic partners to help achieve this.

Our comprehensive range of materials extends from isostatically molded, extruded, die-molded and vibration-molded graphite through to carbon and graphite felt and carbon fiber-reinforced carbon. We optimize them to the needs of our customers by drawing on our expertise in the planning, design and processing of complex components made from these materials. Finishing options such as coating, impregnation and purification complete our product portfolio.

Production sites in Europe, North America and Asia supply our materials to our own machining centers, which are located close to our customers worldwide.Our Business Segment Automotive & Mechanical Applications sup-plies carbon and graphite components to the automotive industry, the home appliances industry and mechanical engineering compa -nies. Our customers include manufacturers of compressors, vacuum pumps, vane pumps, sealing systems and sliding elements, as well as processors of semifinished products.

| Packaging Detail:Standard exported packing or according to the clients' requirements |

| Delivery Detail:7-10 working days after receive the payment |