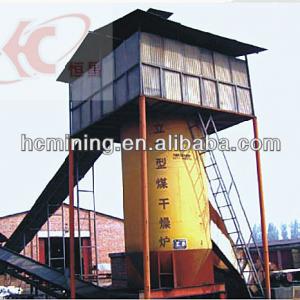

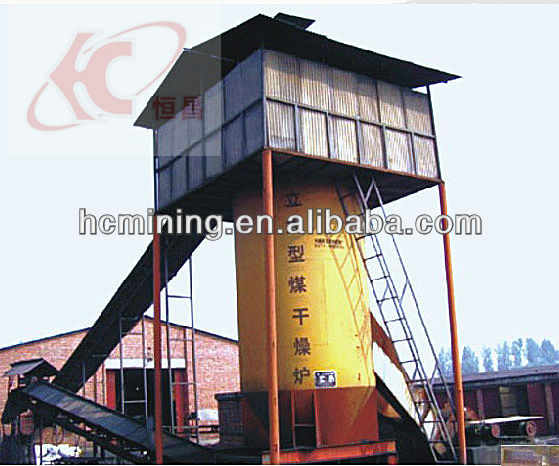

Good quaity High production Vertical Dryer for coal briquette

| Condition:New | Type:vertical dryer | Place of Origin:Henan China (Mainland) | Brand Name:HC |

| Model Number:LH | Power(W):11-37 | Dimension(L*W*H):Refer to the specification | Certification:IO9001:2008, CE |

| Warranty:ONE YERA | After-sales Service Provided:Engineers available to service machinery overseas |

Vertical Dryer for coal briquette

Introduction:

Vertical Dryer is used for drying coal briquettes, it has the features of convenient operation and easy maintenance. The machine has no mechanical running part, so it needs less daily maintenance. Owns the characteristics of continuous operation, high efficiency, large capacity, high automation degree, and reliable operation, so vertical dryers can save labor, reduce labor intensity, save yard, and expanded production capacity.

1. Function ofvertical dryer for coal briquette

Vertical dryer is designed for the dehydration of briquette and pellet. It has reasonable design, high thermal efficiency, good drying effect and adjustable air volume.

This type of vertical dryer is made of steel structure; inner lining adopts heat preservation materials to keep warm; multilayer high temperature castings are adopted in the roaster, fixed barrel, turnover wind system, heat-exchanging system, attemperator.

2. Working principle ofvertical dryer for coal briquette

The molded balls which contain much moisture are transmitted to the top by conveyor, and then they are evenly distributed on the top cross-section by distribution device. Briquettes fall down slowly by gravity, exchange heat with strong wind at the same time.

The moisture which is evaporated from briquette is taken away randomly by the strong wind. The briquettes achieve intensive drying after two hours evaporation process.

3. Application ofvertical dryer for coal briquette

Material is pressed into shapes by briquette press machine; the moisture is usually at 12%-14%. After dried, the moisture can reduce to 2-4%, also can satisfy the request of hardness, storage and transportation.

4. Economic features ofvertical dryer for coal briquette

Economic characteristics: the amount of investment reduced by 1/2; area is 1/5-1/3; energy consumption and operating costs significantly reduced.

Advantages: This product matching process is good, easily in connection with other equipments and automation in production line. Equipments are easy for operation and simple for maintenance. Drying furnace body has no mechanical moving parts, no maintenance routine. It is characterized by continuous operation, high efficiency, large output

Technical Parameters:

| Model | Moisture before Drying (%) | Moisture after drying (%) | Coal Consumption (kg/h) | Drying Hour (h) | inlet air temperature (°C) | Dry Capacity (t/h) | Power (kw) |

| LH-1800 | 8-12 | 3-5 | ≤40 | 2-2.5 | 200-260 | 2-3 | 11 |

| LH-2800 | 8-12 | 3-5 | ≤100 | 2-2.5 | 200-260 | 6-8 | 22 |

| LH-3200 | 8-12 | 3-5 | ≤150 | 2-2.5 | 200-260 | 13-15 | 37 |

Certification and honors:

Our factory and customers:

| Packaging Detail:standard packing |

| Delivery Detail:20-30days after receive the 30% T/T deposit |