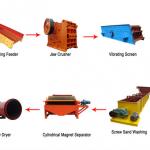

Gold processing plant/Gold washing machine/Gold wash plant

| Condition:New | Type:Flotation Separator | Production Capacity:10-3000t/d | Place of Origin:Henan China (Mainland) |

| Brand Name:GHM | Model Number:500t/d | Voltage:380/440V | Power(W):210000 |

| Dimension(L*W*H):3600x2100x2100 | Weight:40t | Certification:ISO9001/CE | Warranty:1year |

| After-sales Service Provided:Engineers available to service machinery overseas | colour:customers requirement | application:Processing of gold ore and sand gold | mineral processing technology:Flotation and gravity separation method |

| Electrode protection grade:50HZ-60HZ | installation and trial run:Our engineer instruction | mode of operation:can 24 hours continuous | Reducer Model:national standard |

| Material:Q235 | easilydamagedparts:manganese alloy | Motor type:synchronous motor |

Gold processing plant/Gold washing machine/Gold wash plant

Henan Gude Heavy machinery manufacturing co., LTD With large numbers of research institutes(machinery research institute, mine design research institute, installation and commissioning department, etc.) and service engineers, our customers have a tremendous depth of technical resources they can rely on. What is more, 80% equipments for mineral processing have been improved by Xinhai and some technologies reach the international advanced level. Xinhai Mining Machinery Company has become the research & developing base of mining and mineral processing machinery industry in China.

In addition, Gude is committed to providing premium EPCM services for customers, which include mineral processing test, mine design, equipment manufacture, installation and commissioning, personnel training and target achievement. There are more than 400 high-performance EPCM projects all over the world which are provided by Gude Company.

What you need is what we can do. For an evaluation of your needs, please contact us at any time. Xinhai believes you will be impressed with the experience, the proficiency and the helpful attitude you find at every level withinHenan Gude Heavy machineryCompany.

gold mining bed type is mainly divided into two categories:

(1)A gold ore deposits are mostly located in mountainous areas, by internal forces geological formation, gold ore, also known as gold mine, endogenous gold mine;

(2)The other for the gold placer gold particles by mountain gold mine out of the ground, broken into long-term weathering and erosion, sequin, gold at the end, and by handling the role of wind, water and other water sorting together deposited in Riverside, Lakeside, Coast to form alluvial, alluvial type or seaside molding sand gold deposits, some mountain gold mine weathering and erosion, debris accumulation of the product in place, the formation of the gold deposits of residual sand; piled along the slopes , the formation of slope plot molding sand gold deposits, placer deposits, also known as exogenous gold mine, its metallogenic epoch in the Paleozoic, Mesozoic, Tertiary, and Quaternary or modern.

In addition, there is an associated gold deposits, its low gold often be recovered in the process of non-ferrous metal mines, and comprehensive utilization.

Alluvial gold ore beneficiation principle is that: using gravity separation to recover gold and all kinds of associated heavy minerals from the ore mineral sands as much as possible. Then gravity separation, flotation, mercury mixing, magnetic separation and electrostatic separation are combined to separate the gold and all kinds of heavy minerals, which can reach the purpose of comprehensive recovery. The gulch-gold gravel mine beneficiation can be classified into crushing and sieving, desliming and beneficiation.

Gold processing plant/Gold washing machine/Gold wash plant for Gold ore Crushing and sieving

Gold processing plant/Gold washing machine/Gold wash plant for Gold ore Declining Desliming

Gold processing plant/Gold washing machine/Gold wash plant for Gold ore beneficiation production line process:

Mining gold ore first preliminary crushing by jaw crusher, crushing to a reasonable degree of fineness via hoist feeder evenly fed into the ball mill, ore crushing, grinding by ball mill.

After a ball mill grinding of ore fines go to the next step:classification.Spiral sorting machine by means of the proportion of solid particles precipitated in the liquid at different speeds principle,the ore mixture enters the grading machine washing,grading.

After washed and graded mineral mixture through the separator, due to the different than the susceptibility of various minerals, via magnetic and mechanical forces Mixture magnetic substance separated.

Adding different drugs through the magnetic separator after the initial separation of the mineral particles in the flotation machine is fed, depending on the mineral characteristics,so that the minerals and other substances to be separated.After the desired minerals are separated out, because the preliminary concentrated containing a lot of water,subject to the concentrator, and then through a dryer to obtain dry minerals.

Flotation process is one of the most widely used methods to process lode gold in gold beneficiation plant. In most instances, flotation process is used for processing sulfide minerals gold ores with high flotability and the effect is most notable. In recent years, the flotation process in gold ores has large evolution. The main performances are innovation process, new drug researching and design improving. Using stage grinding and stage beneficiation process is development trend of gold flotation extraction at present. Many foreign gold beneficiation plants use two stages even three stages and the gold recovery can be improved by 2%-6%. For the flotation process only can enrich the gold into all kinds of sulphur mineral concentrates as much as possible and the final gold products can not be got. Therefore, the beneficiation plants that use single flotation flow are not so much. The flotation process is only used as a process in combination flow.

Our service

1. Providing beneficiation technology and consultation

2. Raw ore testing and evaluation

3. Site chosen consultation and evaluation.

4. Site design and layout design.

5. Installation, erection, and commissioning instruction

6. Workers' training.

Gold processing plant/Gold washing machine/Gold wash plant manufacturer

As a professional manufacturer of mining equipment, Henan Gude Mining and Construction Machinery Co., Ltd. can provide you with both complete production line and independent machine. If you need any help about buying gold ore beneficiation equipment, please feel free to contact us. We are glad to offer service to you.

| Packaging Detail:Standard export container, or in bulks, bare main machines, motors and small parts are packed in wooden cases. |

| Delivery Detail:20 working days |