GMT21 Gantry Milling Machine Gantry Moving

| Condition:New | Place of Origin:Shandong China (Mainland) | Brand Name:CHTEM | Model Number:GMT21 |

| Type:Horizontal,Gantry Milling Machine Gantry Moving | CNC or Not:CNC | Voltage:According to client site voltage | Power(W):22 Kw |

| Dimension(L*W*H):T slot size: 22x11 | Weight:Max weight of workpiece: 25 Tons | Certification:ISO9001:2008; CE Certificate | Warranty:One year |

| After-sales Service Provided:Engineers available to service machinery overseas | Material:High grade cast iron | Production period:4-5 months | Color:Blue and grey and black |

| Functions:Milling, drilling, reaming, tapping | Package:Fumigated wood cases | Guarantee:One year guarantee | Payment terms:T/T; L/C |

| Trade terms:FOB; CIF; DDP; CFR | Transportation:Seaway or railway |

Gantry Milling Machine Gantry Moving GMT21

(Designed and made in Qingdao Shandong, China)

1.Brief introduction :

GMT21machine is Gantry-type machining center with movable cross-rail and column. It features longitudinal movable planner, up-down movement of the cross-rail, fixed stable, large bearing capacity and well accuracy. It can mill, bore, drill various complicated workpieces in manufacturing industries such as aircraft, mould, ship, automobile, and etc.

Machine adopts fixed worktable and gantry moving structure. The gantry (X axis ) is driven by double AC servo motor and moved on the slide base. All axes movement are driven by Siemens AC servo motor. The movement of cross-rail is driven by double AC servo motor.

GMT21 ismade by the standard of ISO and can achieve various machining, milling, boring, drilling, rigid tapping and profile milling. Multiple accessory head can be equipped with the machine, in order to perform one time step up and five face machining.

Machine has good character in high rigidity, excellent accuracy and big output power. Extralong distance gantry travel can ensure best machining accuracy and highest productionefficiency when machining long guide way of heavy duty machine tool. During machiningprocess for short work-piece, the operator can load and unload another part to save auxiliary time and improve efficiency. Thereby,GMT21is the best choice for machining of base component in follow industry, heavy duty machine tool, heavy duty machinery, steel rolling mill, steam turbine and big reduction equipment.

2.Main specifications of gantry milling machine:

| Item | Unit | Value |

Spindle | ||

| Motor power | KW | 22 |

| Spindle speed | rpm | 20-2000(Op:6000rpm) |

| Spindle taper | ISO50 (7:24) | |

| Diameter of spindle bearing | mm | 100 |

Travel | ||

| X axis travel(Worktable) | mm | 2200-6200 |

| Y axis travel (spindle travel in crossbeam) | mm | 2300 |

| Z axis travel (Spindle vertical travel) | mm | 1000 |

| Distance from spindle nose to worktable | mm | 2000 |

| Distance between two columns | mm | 2100 |

Worktable | ||

| Worktable size (L x W) | mm | 1600x2000 |

| Worktable loading capacity | kg | 25000 |

Feeding | ||

| X axis rapid travel | mm/min | 8000 |

| Y axis rapid travel | 8000 | |

| Z axis rapid travel | 2000 | |

| Feeding rate | mm/min | 5-4000 |

Accuracy | ||

| X axis positioning accuracy | mm | ±0.02/1000mm |

| Y axis positioning accuracy | mm | ±0.02/1000mm |

| Z axis positioning accuracy | mm | ±0.02/1000mm |

| Repetitive positioning accuracy | mm | 0.015/1000mm |

3. General terms:

3.1 Payment terms:30% of the whole contact value as down payment by T/T.The last 60% of the wholecontact value should be paid byT/T before shipment after the final testing and inspection.

3.2 Delivery time:120-140days from the date we received the advance payment.

3.3Warranty and after sale service

1, Warranty period: one year after final installation, during the warranty period, all the daily damage parts will be provided freely by the manufactory.

2, Out of warranty period, the factory will still supply the support for the whole life of the machine, including technical advice, spare parts, labor, after sales service, and so on. But the factory will just take the necessary cost.

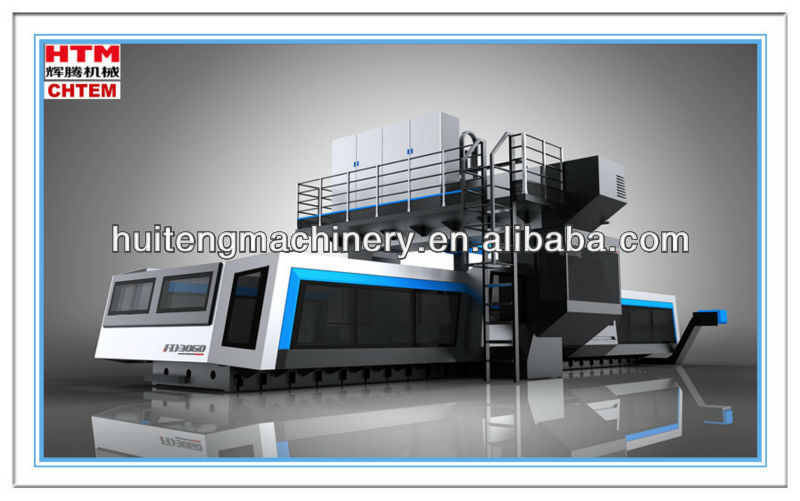

4. Pictures:

4.1 Pictures of gantry milling machine:

4.2 Pictures of gantry milling machine loading:

4.3 Pictures of machine commissioning:

4.4 Pictures of our workshop:

| Packaging Detail:Dismantled into fumigated wood cases, loaded into containers. |

| Delivery Detail:2-3 months |