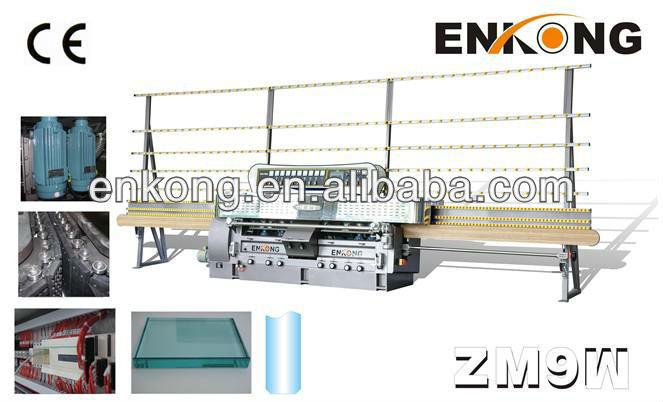

Glass edging machine with bearing system

| Condition:New | Machine Type:Glass Edging Machine | Place of Origin:Guangdong China (Mainland) | Brand Name:ENKONG |

| Model Number:ZM9W | Voltage:415V/380V/220V | Power(W):50HZ/60HZ | Weight:4000KGS |

| Certification:CE | Warranty:One year after delivery | After-sales Service Provided:Engineers available to service machinery overseas | ABB motors:For grinding |

| Frequency inverter:For processing speed | Bearing system:For Main transmission |

1.Brief Description

1.ZM9Wis suitable for processing straight-line edge & 45°arrises of glass sheet with various size and thickness.

2.The front and rear chain pad using bearing system. And it is specialize in small size and thick glass sheet.

And carrying capacity is very strong. And with good waterproof construction. At the same time with highly processing precision.

3.All grinding motor used ABB Motor. And the motor with longer service life.

4. A special design of the in-feed section for controlling the desired amount of glass removal without adjusting each spindle individually.

5. Independent felt wheel and the cerium water recirculation system make the flat edge more shining.

6. Input and output conveyor adopt timing belt which can improve the transmission precision.

7. It is easy to operate and has good performance.

2. Technical parameter

1. Processing glass thickness: 2~28mm

2. Angle of arris:45°

3. Min. size of glass:40mm×40mm

4. Processing speed:1.0~5 m/min

5. Installed power: 22.6 KW

6. Occupation: 8.8m×2.2m

7. Power depends on your requirement.

8. Weight: about 3000KGS

10.Stainless steel water tank

11.The infeed and outfeed adopts Timing belt to convey.

12. Most of Electrical components adopt Schneider (Made in Germany)

13.Wheels arrangement

No.1 Diamond wheel 100mesh

No.2 Diamond wheel 180mesh

No.3 Front arris resin wheel 240mesh

No.4 Front arris 10S40 wheel (Made in Italy)

No.5 Rear arris resin wheel 240mesh

No.6 Rear arris10S40 wheel (Made in Italy)

No.7 Resin wheel 320mesh

No.8 Fine grinding wheel 10S40 (Made in Italy)

No.9Wool felt wheel with cerium oxide (Made in Italy)

3. Electric configure

1. PLC Control with touch screen

2. The processing speed controlled by frequency inverter

3. The wool felt wheel with pneumatic polishing

4. The mainly electrical element using Schneider.

4.Glass samples

The electrical cabinet( Schneider PLC)

Wheels arrangments

.

Bearing system for main transmission

| Packaging Detail:IRON PALLET OR WOODEN PALLENT WITH FILM PACKAGE |

| Delivery Detail:30DAYS AFTER RECEIVED FULL-PAYMENT |