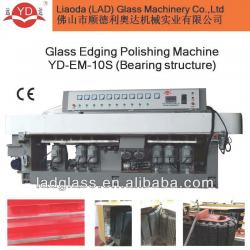

Glass edge polishing machine YD-EM-10S

| Condition:New | Machine Type:Glass Edging Machine | Place of Origin:Guangdong China (Mainland) | Brand Name:YD |

| Model Number:YD-EM-10S | Voltage:220/380/415/480V 50/60HZ | Power(W):24.5kw | Dimension(L*W*H):7500x1000x2600mm |

| Weight:4500KG | Certification:CE | Warranty:1 year | After-sales Service Provided:Engineers available to service machinery overseas |

| Vertical:straight line edging | Straight:line edging |

Glass edging polishing machine:

Functions:

Processes rectilinear glass plates in various sizes and thicknesses;

The grinding (roughing), finishing resin and fillets can be performed simultaneously;

The same thickness as the glass sheet can be continuously processed, so that the machine allows having a larger volume of production lines hardening processes, rolling processes and other processing.

Glass type: Float glass for furniture, building, door, windows, home appliances etc

Technical data

| Item | Specification |

| Maximum flat edging level: | 3mm |

| Maximum arrising width: | 2.5mm |

| Arrise angle: | 45° |

| Max. glass size: | 3000x3000mm/2440x3660mm |

| Min. glass size: | 30x30mm |

| Glass thickness: | 3-26mm |

| Installed power | 24.5kw |

| Working speed | 0.7-5.0m/min |

| Weight | 4500kg |

| Worktable height | 750mm |

| Overall dimension (L.W.H) | 7500x1000x2600mm |

Wheels arrangement:

| # | Wheels | # | Wheels |

| 1 | Diamond wheel,bottom edge | 6 | Resin wheel for arris |

| 2 | Resin wheel,bottom edge | 7 | BD wheel for arris |

| 3 | Resin wheel,bottom edge | 8 | Yew wheel for bottom edge |

| 4 | Resin wheel for arris | 9 | Yew wheel for bottom edge |

| 5 | BD wheel, arris | 10 | Woolly wheel, bottom edge |

Machine characters:

Control system: MCU, Micro-computer

Bearing structure conveyor, has longer life time than chain structure edging machine

Speed control: Frequency speed control

Glass thickness adjusted on the control panel.

2pc of stainless steel water tank

Steel glass support

Rail height adjustable

| Packaging Detail:The main struture(processing part) and support part (water container, support flame) are seperated. Before wrap the machine with plastic bubble sheet, anti-rust oil will be spread easy to rust part. Then each parts will be fixed on pallet or wooden box are requirement. |

| Delivery Detail:1 months after 30% of down payment |