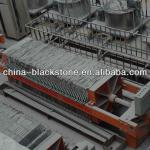

Fully-automatic High Pressure Membrane Filter Press

| Condition:New | Automatic Grade:Automatic | Place of Origin:Hainan China (Mainland) | Brand Name:Jincheng |

| Model Number:XMJY/870-30U | Voltage:380V | Weight:4500kg,4500Kg | Dimension(L*W*H):4560*1390*1250mm |

| Certification:ISO9001:2008 | After-sales Service Provided:Engineers available to service machinery overseas | Filtering area:60m^ | Filter board specification:870*870 mm |

| Thickness of press cake:30mm | Clapbord number:22pis | Film board number:23pis | Volume of filter chamber:920L |

| Filtering pressure:0.5Mpa | Outling dimension:4560*1390*1250mm |

Fully-automatic High Pressure Membrane Filter Press

Membrane filter pressconsists of membrane plate and filter chamber made of ordered filter plates. The slurry materials are sent to filter chamber by the pressure of feeding pump and then go into filtrating media (filter cloth) to separate solid and liquid in slurry material. When solid in slurry material becomes cake shape, air is sent to membrane to fully squeeze the solid to reduce moisture content. If users have high requirement about filtration of sticky material and moisture content ratio, this machine has its own special characteristics to meet the need.

Advantages of membrane filter press:

- Increased product throughput

- Reduction of the residual moisture of the filter cake

- Shorter filtration, wash and cake cycles

- Drier cakes means energy saving on cake drying and transportation

- The optimized cake structure facilities quicker and better washing results

- Varying product quantities and compositions present no problems to the membrane filter press

- High degree of automation, labor-saving and ease to operate:adopting PLC control system, including automatic keeping pressure, automatic pulling board, quick program functions,ect.

Applications of membrane filter press:

·Commodity and Specialty Chemicals

· Pharmaceutical Raw Materials and Intermediates

· Food Products and Ingredients

· Clay and Ceramic Powders

· Dyes and Pigment

· Industrial Waste Dewatering and Recycling

· Oil industry

Product components of membrane filter press:

Resist-bending main bean:main beam with H-van structure is rigid and anti-bending, which completely solves the main beam bending problem.

Reinforced polypropoly membrane filter plate:Crush resistance,heat-resistant,anti-corrosion, alkali and acid resistance, nontoxic and odorless.

Filter media (filter cloth):Polypropylene; Teflon; Polyster; Cotton; Nylon. Filter media chosen is based on your specific operating conditions, the performance required by the filtering media.

Antiseptic treatment:

Antiseptic treatment can be made according to the customer’s requirements or the feed’s PH: the frame can be covered by SS, PP material, and spray-paint treatment. Spray-paint has the best preservative effect.

Hydraulic station:

The automatic hydraulic station is used for pressing and releasing filter plates. The electrical contract pressure gauge is available to automatically maintain pressure. The operation of automatically pushing and pulling filter plate can realized by the automatic shifting device which is driven by Integrating motor with fluid power

1.high output force

2.accurate hydraulic pressure

3.no corrosion

4.continuous variable transmission

Motor:Motor is ABB product , and has smooth and reliable operation, low power consumption.

Automatic plate shifting device:

Membrane filter press main parameter:

| Parameter | Filter area m2 | Filter board specification mm | Thickness of press plate mm | Number of filter plate piece | Cubage of filter chamber L | Filtering Pressure Mpa | Rating Pressure of cylinder Mpa | Oil cylinder maximum trip mm |

| Model | ||||||||

M XZ/1000-U A | 100 | 1000×1000 | 30 | 58 | 1480 | 0.5-1.6 | 25 | 550 |

| 120 | 70 | 1780 | ||||||

M XZ/1500-U A | 400 | 1500×1500 | 35 | 99 | 5690 | 0.5-1.6 | 18 | 800 |

| 500 | 125 | 7510 | ||||||

M XZ/2000×1500 -40U A | 600 | 2000×1500 | 40 | 113 | 11980 | 0.5-1.2 | 18 | 800 |

| 800 | 151 | 15970 | ||||||

| M X Z/2000-4U A | 600 | 2000×2000 | 40 | 82 | 8960 | 0.5-1.2 | 18 | 800 |

Our Certification

CE, ISO9001:2008,etc.

| Packaging Detail:in wooded case or in standard container |

| Delivery Detail:15 woking days |