full automatic and water saving cassava flour full making machine

| Condition:New | Place of Origin:Henan China (Mainland) | Brand Name:GOODWAY | Model Number:GD-CF-110 |

| Type:crusher,GD-CF-110 | Voltage:380v | Power(W):100kw | Weight:20ton |

| Dimension(L*W*H):2 40"container | Certification:ISO certificate | Warranty:1 year | After-sales Service Provided:Engineers available to service machinery overseas |

| operation:cassava flour full making machine | power:22kw-90kw | useful life:10 years | effenicient:produce 4 ton to 10 ton per hour |

| shipment:ocean shipment | packaging detail:standard sea packing | warranty period:5 years | material:stainless steel |

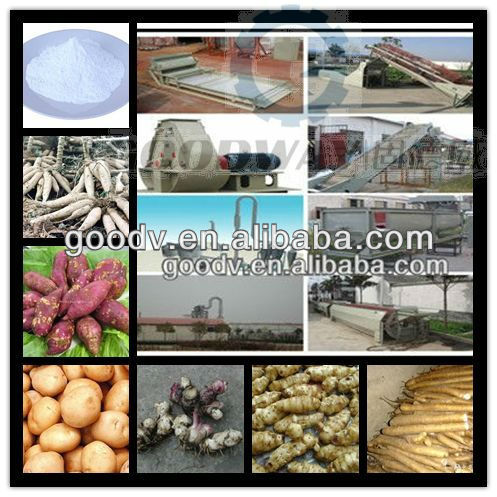

full automatic and water saving cassava flour full making machine

1.About Goodway factory:

ISO 9001:2008 Certified ISO

20 National Patents Owned up to now

A Supplier in Starch Machinery for over 20 years.

More than Machinery, Engineering and projecting for each of our customers,

An Superior Cooperator with latest technology resources, such as Henan Agricultural University and Chinese

Academy of Agricultural Sciences.

Reliable not only in quality and services, but also cost saving.

2.Introduction Cassava/Yam/potato(...)starch production line working flow(1)

First process is transportation and cleaning

Collect the fresh cassava from stock ground, and transported by the conveyor belt to peeling machine for peeling

and stone removing. After firstly remove the impurities on the surface, the cassava is transported into washing

process. After washing twice by trough conveyor and roller, the sediment and impurities on the surface of cassava

have been basically removed; and peeling rate can achieve 80%. After cleaning process, the cassava will be

transported into the crushing process.

Second Crushing, concentrating and refining section

1. First we use a primary crusher, this grinder designs two stages of grinding: first is thorn nail roller method grinding, second is the hammer type. This design ensures the cassava get fully crushed and using less energy than the traditional way. This grinding is better to add less water or no water. Cassava flour processing requires higher fineness of the grinding. The material after grinding is no need for screening in order to avoid the loss of nutrients. In order to guarantee the flavor, color and lustre of cassava flour, the crushing material must take the oxidation process (fermentation).

2.Then several fermentation tanks should be built for leaving the crushed mash cassava materials fermented 3-7 days according to the temperature.

Note: This fermentation process can keep the sour flavor of the flour.

3.Fermented material pumped out into this fine mill by mash pump, then get fine milled into small and uniform particles (with water in the mash).

Third Dehydration, Drying and packing Section

1.We use a dewatering machine, This dewatering machine ensures the continuity of the whole processing process.

Note: centrifugal machine and plate-type filter presses also can be used for dewatering the mash materials, but not continuity.

2.Used a conveying machine to convey the wet materials after dewatering to the feeding inlet of the drying machine. Wet material enter into the drying tube through powder feeder, then mixed with the fresh air which heated by radiator. Wet material suspended in hot air by the power of wind machine and can get dried by heat exchanging of heat and mass transfer process.

The advantage and main machine of the cassava/yam/potato starch production line

1.Fully automatic line, connected well among all components.

2.Saving manpower, just need 5-6 persons to operate the complete line because we use advanced technology to form it very automatic.

3.Saving 30% power and water.

4.Flour quantity from our machine is really high which can be made into some more delicious food like cake, bread

and garri,etc.

3.Introduction Cassava/Yam/potato(...)starch production line working flow(1)

We have another work flow: washing and peeling----slicing----Crushing and packaging

Customer can choose the suitable work flow according to their demand.

4.Cassava/Yam/potato(...)starch production line Customers:

If you want to more information ,pls send me e-mail or as contact below:

Name: Nada Wang

Phone:008613700841969

Skype:nada-wang

| Packaging Detail:wooden casecassava flour full making machine |

| Delivery Detail:15 days |