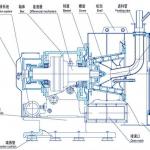

Fruit Juice Centrifuge Separator

| Place of Origin:Central African Republic | Brand Name:ZL | Model Number:DHF | Capacity:50L/h-10000L/h |

Fruit Juice Separator

Fruit Juice Centrifuge

Large volumes of fresh water are required for cleaning the fruit, pipework, storage tanks and bottles.

Mechanical separation technology from us provides a range of benefits for treating waste water in fruit

juice production and achieves excellent results due to its closed design and high dewatering capacity.

Numerous substances are retained in the wash water during the cleaning of pipework and storage tanks.

Many valuable organic substances (fruit residues with a high sugar content) have to be separated because

fermentation would otherwise start very easily. Residues of chemical substances (insecticides) from

cultivation and residues from the production process also have to be removed completely. This means that

the wash water has to be treated thoroughly because it cannot be discharged into the sewerage system

in this state. Mechanical separation of the solids with modern technology from us is the ideal solution.

Waste water treatment in fruit juice production

After straining and biological pre-clarification in activation tanks, decanters thicken the residual sludge

and the volume of the sludge is reduced; the discharged solids are of a crumbly consistency and can be

disposed of inexpensively. The treated water can be recycled into the cleaning cycle or discharged into

the sewerage system in an environmentally friendly manner. The volume of fresh water consumed is

reduced, resources are used efficiently and energy costs are lowered. In this way, decanters from us

make a major and inexpensive contribution towards ensuring that everything is in its rightful place:

the vitamins in the juice, and clean water in the cycle of nature.

| Packaging Detail:Standard wooden case |

| Delivery Detail:30days |