frp filament winding machine

| Type:Pipe Production Line | Pipe Material:fiber glass | Application:Energy Supply Pipe | Place of Origin:Hebei China (Mainland) |

| Brand Name:zlrc | Model Number:zlrcw-1 |

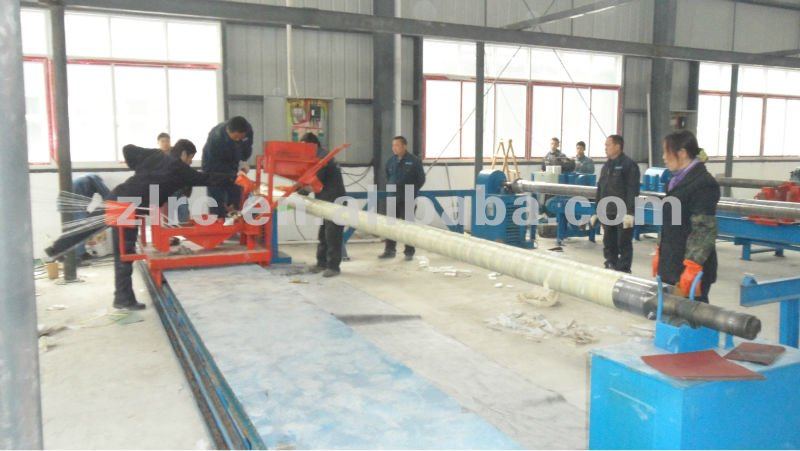

FRP/GRP Continuous winding machine

simple control on producing techniques, better working atmosphere, stable pipe quality

FRP/GRP pipe continuous production line

- Performance feature

Feature: the great advantages are simple control on producing techniques, better working atmosphere, stable pipe quality, adjustable pipe length, easier to change specifications, more convenient operation, etc.

| FWJS-1500 | FWJS-2600 | FWJS-3000 | |||

Pipe diameter(mm) | DN300-DN1500 | DN300-DN2600 | DN300-DN3000 | |||

Production length(mm) | ≤12300 | ≤12300 | ≤12300 | |||

Winding angle range | 45°-90° | 45°-90° | 45°-90° | |||

The way of adding sand | Both dry and wet | Both dry and wet | Both dry and wet | |||

Max thickness of adding sand a time(mm) | ≤20 | ≤20 | ≤20 | |||

Rotating speed of main shaft(r/min) | ≤85 | ≤85 | ≤85 | |||

Max speed of pulling yarn(m/min) | ≤120 | ≤120 | ≤120 | |||

Production capacity(kg/h) | 1800 | 2300 | 3200 | |||

Total installed capacity(KW) | 110 | 120 | 120 | |||

Areas covered by production line(length×width)m | 54x24 | 60x24 | 60x24 |

Basic allocation of production line

Liner making machine: It is set up with Taida PLC numerical control device. The winding film, mat and gridding fabric can be controlled automatically by the tension bracket device which makes the lap joint is smooth and precise, so the artificial nonuniformity and waste phenomenon will be prevented.

Winding machine: The sand-adding method includes many modes: intermediate, bottom, dry, wet and dry-wet method. By being set up with automatic glue-supplying pumping station and mixer, ratio of sand inclusion is fully automatic and well-distributed, so the operation of the equipment is pretty convenient and accurately, low energy-consuming.

Curinging station: It includes open style and closed style. It’s allocated with infrared heating system and the mould revolves automatically.

Demoulding machine: It adopts hydraulic transmission and the movement is stable. The flexible distance of claw is long and the applying scope of diameter is wide. It saves the usage of mould-extracing loop so the operation is easier.

Double-duty machine of mandrel: With the collocation of highly-accuracy lathe bed, splint and splint-driven system, it can trim the pipes and also manufacture the moulds, by this way, the double-duty utilization is realized, which can save a lot of investment on mould for customers.

Standard Collocation:

Liner making machine of FRP pipe

Winding machine of RPMP/1 set

Curing station of pipe /4 sets

Trimming machine for pipe bell and spigot

Pipe mold release machine of hydraulic pressure type

Option Collocation:

Mold making machine of pipe

Digital control system of trimming on pipe bell and spigot

Resin pre-accelerated agitator tank

Adjustable resin pump

| Packaging Detail:normal export package |

| Delivery Detail:25days |