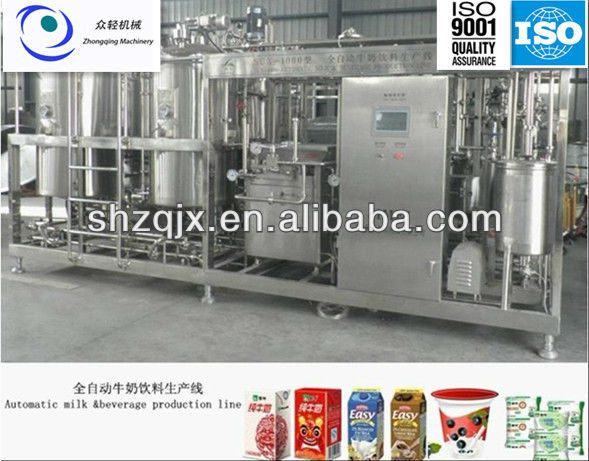

fresh milk processing plant

1.dairy milk production factory, 2.CE compliant, 3.CIP cleaning system, 4.pasteurizer and homogenizer .5.MOQ:1set - details see: https://www.machineto.com/fresh-milk-processing-plant-10029072

| Processing:Other | Condition:New | Place of Origin:Shanghai China (Mainland) | Brand Name:Shanghai zhongqing |

| Processing Types:Milk | After-sales Service Provided:Engineers available to service machinery overseas |

| Fresh milk equipment list(5T/D) | ||||||||

| specification | Main technical parameters | Unit | Quantity | Equipment manufacturer | unit price | Total price | ||

| 1 | Before the dairy production processing | |||||||

| 2 | storage tank | 2000L | Inner shell:SUS304, 2.5mm,outside shell;2mm,CIP cleaning head,paddle blending,1.5kw.Manhole covers,thermometer,Sampling valve,Adjustable bracket | 2 | ShanghaiQingJi | |||

| 3 | Doule fillter | 5T/h | SUS304, stainless steel filter 100 mesh | 1 | ShanghaiQingJi | |||

| 4 | milk pump | 3T/H | SUS304,lift:24M | 3 | ShanghaiQingJi | |||

| 5 | Board type cooler | 12M², | SUS304, single zone. | 1 | ShanghaiQingJi | |||

| 6 | Board type cooler | 20M², | SUS304, single zone, 40°Ccooling to 4°C | 1 | ShanghaiQingJi | |||

| 7 | Net milk machine | 5T/h | Contact materials materials for 304, automatic slag discharge, | 1 | made in China | |||

| 8 | storage tank | 8000L | .Inner shell:SUS304,4mm,outside shell;2mm,CIP cleaning head,double paddle blending,2.2kw,thermometer,Sampling valve,Adjustable bracket | 2 | ShanghaiQingJi | |||

| 9 | storage tank | 2000L | SUS304,sterile tank, Inner shell:2.5mm,outside shell;1.5mm,CIP cleaning head,paddle blending,1.1kw,thermometer,Sampling valve,adjustable bracket | 2 | ShanghaiQingJi | |||

| 10 | High-speed Super-fine Emulsification Tank | 500L | .Sus304, inner container: 2.5mmm miller jacket: 1.5mm, CIP cleaing head, high speed shear head, 7.5kw, thermometer | 1 | ShanghaiQingJi | |||

| 11 | liquid composing tank | 2000L | .SUS304, Inner shell:2.5mm,Jacket Miller board1.5mm, outside shell;1.5mm,CIP cleaning head,double paddle blending,2.2kw,thermometer,Sampling valve,Adjustable bracket | 4 | ShanghaiQingJi | |||

| 12 | Tube type filter | 2T/h | SUS304, stainless steel filter 100 mesh | 1 | ShanghaiQingJi | |||

| 13 | Platetype sterilization machine | 1T/H | SUS304, sterilization temperature of 95°C, heat preservation 15 S, discharging temperature 4°C, balance slot, automatic control. | 1 | ShanghaiQingJi | |||

| 14 | Pipe type sterilization machine | 1.5T/H | SUS304, sterilization temperature of 137°C, heat preservation 20 S, discharging temperature 25°C, balance slot, automatic control. | 1 | ShanghaiQingJi | |||

| 15 | Heat preservation tank | 300S | SUS304, adjustable bracket | 1 | ShanghaiQingJi | |||

| 16 | storage tank | 1000L | Inner shell:SUS304,2.5mm,outside shell;1.5mm,CIP cleaning head,frame blending,1.5kw,thermometer,sampling valve,adjustable bracket | 2 | ShanghaiQingJi | |||

| 17 | Homogeneous pump | 1T/h | Pressure 25 MPa, Start ark | 1 | ShanghaiQingJi | |||

| 18 | Fermentation tank | 2000L | .Inner shell:SUS304,3mm, Jacket miler board 1.5mm, outside shell; 2mm, Vertical blending 30 turns/min, frame blending, CIP cleaning head, thermometer, built-in scale, sampling valve,adjustable bracket | 2 | ShanghaiQingJi | |||

| 19 | Seeds tank | 300L | SUS304.inner shell:2mm,Jacket miler board 1.5mm, outside shell:1.5mm, paddle blending. | 1 | ShanghaiQingJi | |||

| 20 | Yogurt turn cylinder cooling plate | 16m² | SUS304, cooling process 42°C-18°C, stainless steel frame, stainless steel electric control cabinet, plate heat exchanger (special) pneumatic valve, electromagnetic valves, etc | 1 | ShanghaiQingJi | |||

| 21 | storage tank | 2000L | Inner shell:SUS304,2.5mm,outside shell;1.5mm,CIP cleaning head,frame blending,1.5kw,thermometer,sampling valve,adjustable bracket | 2 | ShanghaiQingJi | |||

| 22 | Rotor pump | 2T/H | Speed range 0-500 PRM, 2.2 Kw motor, frequency conversion control | 1 | Shanghai | |||

| 23 | Screw pump | 5T/H | Speed range 200-500, 3 Kw motor. | 1 | Shanghai | |||

| 24 | Seeds tank | 300L | Inner shell:SUS304,2mm,Jacket miler board 1.5mm,outside shell;1.5mm,paddle blending, | 1 | ShanghaiQingJi | |||

| 25 | CIP cleaning system | 600L | SUS304, semi-automatic control, cleaning fluid temperature automatic control, acid, alkali, hot water and inlet steam pressure reducing valve , pneumatic steam regulator, stainless steel frame, stainless steel pipe valves, fittings, 100 L strong acid, one strong alkali tank, 2 diaphragm pump radios , CIP process pump, stainless steel electric control cabinet. | 1 | ShanghaiQingJi | |||

| 26 | self-suction pump milk | 15T/H | SUS304, 24 M head, CIP return pump. | 1 | ShanghaiQingJi | |||

| 27 | Electrical control cabinet | stainless steel tank, two sets of eight road, a set of 14 road, filling feeding pump thermodynamic control. | 2 | ShanghaiQingJi | ||||

| 28 | Filling equipment | |||||||

| 29 | Plastic bag packaging machine | 4000bag/hr. | Double head, filling capacity of 200 ml-500 ml, power 7.5 Kw, compressed air 0.6 Mpa | 1 | Domestic produce | |||

| Total | ||||||||

| Plastic cup filling sealing machine | 4800bag/hr. | Automatic fall cup, quantitative filling, automatic sealing, etc | Domestic produce | |||||

| Shrink standard set of standard machine | . assorted with filling machine | 1 | Domestic produce | |||||

| Other units | ||||||||

| Process equipment design | Fees on real plan | |||||||

| steel pipe materials, valves, fittings and so on | SUS304, including stainless steel pipe support, etc. (according to the size of production workshop ) | |||||||

| puplic process pipe, wire line and so on | Workshop primary distributs ark, power distribution installation materials (bridge, trough, wire and cable, tap water, ice water, steam pipe materials, insulation materials, heat presevation material,compressed air pipe materials. | |||||||

| Installation commissioning cost | 10% | Equipment in place, installation and debugging. material pipe in workshop, CIP clean pipe, steam, water, ice water, compressed air, and other public pipe installation, and circuit, wire and cable trough frame install the connection, operation platform production. | ||||||

| Engineering unforeseen expenses | Operation platform materials and conveyor belts of finished products , purify air conditioning system between finished product, etc. | |||||||

| Total | ||||||||

| Packaging Detail:Be packed in wooden cases |

| Delivery Detail:1 month |