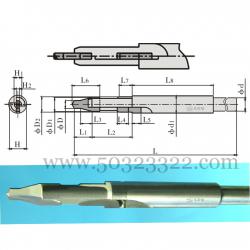

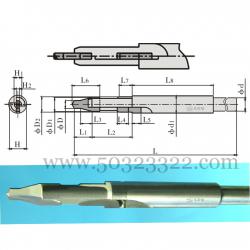

Forming reamer

| Place of Origin:Shanghai China (Mainland) | Brand Name:LZQ | Model Number:custom | Material:Tungsten Steel |

Adopting advanced power high speed CNC grinder from Germany and Switzerland as well as high precision (3DX technology) grinding of high quality super micro-grain tungsten steel (quality carbide), it has perfect flute and size tolerance can up to ±0.001mm(±1μm) high. Cold-hard machining replacing grinding can improve precision, hard milling replacing grinding can improve efficiency.

Type of material K10/HRF10/MR11/MR12/PR40/PRA5/NRA61/PRA11/VRA201/ASP60C/SKH57A/SKH55A/VWA201/SKH4C(Stainless high speed steel)/VWA441/VWA431

VRA201: Imported ultra micro-grain diamond tungsten steel, with excellent impact-resistance and general wear-resistance. Generally applied in worse or general equipment to machine materials of lower hardness HRC≤25°, discontinuous cutting and worse part fixture. Conforming to ISO K25, can replace machining of materials like M42, ASP60, MPM, HSSCo10 etc, and can get 4-6 times lifetime, it has higher performance/price ration. Comparing with SKH51, it has 15-25 times lifetime and durability.

HRF10(NRB10Z/HRD10): ultra micro-grain diamond tungsten steel, has excellent wear resistance, but its impact resistance is not so good. It is applicable for medium and low speed cutting of high hardness materials (HRC45°-65°) requiring thermal refining and quenching or for various materials having higher wear resistance and non-ferrous metal. Generally it is applied in good working condition\stable cutting\excellent part fixing and continuous light machining. Corresponding to ISO K10.

Miniature and profile compound tooling can be machined according to drawing or sample

We can produce special, compound, special-shaped, super-large/ super-small/ super-long combined profiling series tool according to requirements of drawings, samples, and dimension tolerance, keep around RMB 8~10 Million turnover stock articles such as raw material, semi-products, finished products in ordinary year.

When producing in batch, we can produce forming drill bits with many kinds of apex angles, cutting-edge forms and μm dimension tolerance.

LZQ is possessed of cutting-edge & comprehensive production system, as well as rich producing & machining capability with different precision technology, so as to realize high efficiency application.

From high-class products (via 6-axis/ 7-axis Blocking CNC-machine Tool (Class-AAA))to medium-class products (via 3-axis/ 4-axis Blocking CNC-machine Tool (Class-D)), different quality and price, our reliable products can replace to first-class products, and we are professional in wholesale, R&D, producing & processing, as well as design revision according to client's designs and samples of special, non-standard, abnormal shape and new products with high cost-performance ratio, also our on-demand service will decrease your comprehensive cost greatly!

Referencing to the page footer, please provide your sample and specify the detailed specification, material type, size tolerance, drawing of semi-product and finished product, applied equipment, equipment value (RMB, to judge its market value is rigid or floating), monthly consumed quantity, type of original product and its deficiency, when you make inquiry. What is the processed material and its HRC?

| Packaging Detail:custom |

| Delivery Detail:1-3weeks |