Fly ash drying system, fly ash drum dryer

| Condition:New | Type:Drum Drying Equipment | Place of Origin:Shandong China (Mainland) | Brand Name:minchang |

| Model Number:2.2*16 | Voltage:380 | Power(W):37kw | Dimension(L*W*H):2.2*2.2*16 |

| Weight:39T | Certification:ISO9001:2008 | Warranty:2 years | After-sales Service Provided:Engineers available to service machinery overseas |

| capacity:25-35T/h |

Fly ash drying system, fly ash drum dryer :

Model: 2.2*16

Capacity: 25-35T/h

Rotary speed: 4.6r/min

Weight: 39T

Company Introduction:

Jinan Minchang New Energy Equipment Co., Ltd, as the branch company of Zhangqiu Heavy Forging Co., Ltd, is the professional manufacturer of ball mill, lifting hook group, transformer oil tank and steel structure products. Based on the powerful capacity of forging and machining, the main accessories can be done from forging to finish machining by our own, which reduce the cost by a large degree.

Our factory covers an area of 60,000 sm, and are equipped with advanced processing equipments, which include: 5*20m plasma cutting saw machine 3stes, 8m CNC hydraulic guillotine machine, 8m CNC hydraulic press brake, rail type shot blasting machine, CNC steel plate pre-treatment line, CNC open-book leveling line, δ120*3m plate bending roller,Φ6.5*30m barrel processing equipment, 4m vertical lathe, screw type water spray paint room, CNC machine center and so on. Also various methods of inspection can be done.

Our company possesses the Product Quality Certificate awarded by theQuality Inspection Supervision Center of National Hoisting and Conveying Machinery of China, and is qualified to produce 160T Class S and below, 200T Class T and below lifting hook group.

Paul Jing

Sales manager

Jinan MinChang New Energy Equipment Co.,Ltd

Zhangqu Heavy Forging Co.,Ltd

Add: Puji Town, Zhangqiu County, Shandong, China

Tel: 0086-13853179741

Fax: 0086-531-61321918

Email: zqforging at live dot cn

Skype: zfshine

Product introduction:

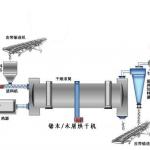

The new type high yield and energy saving drying system adopt low-coal consume, high temperature and quick adjust technique, has rapid combustion burning, competent heat supply an high thermal efficiency, and so on advantages. It adopts various parietal and center new-type lift-material boards, which makes the material whole cross section very uniform; this prevents vacuous heating and raises drying efficiency greatly. It can increase the yield double in size than compare to traditional drying system. Matching aeration and dusting equipments are economical and practical, discharging concentration of wasted steam is lower than national I class emission criteria. Products are widely used for dryingslag, limestone, fly, ash, clay and metallurgical ore and so on materials with definite moisture.

Our company can take reclaiming increase in rebuilding, debugging. Operating and training on drying system on the basis of consumer’s requirements.

Technical Parameter of dryer

| m Specification | t/h Pord capacity | r/min Rotary speed | kw Motor power | Type of reducer | t Weight |

| Φ1.8×12 | 14-25 | 4.8 | 15 | ZQ65 | 24 |

| Φ2.0×18 | 12-28 | 4.8 | 30 | ZQ65 | 37 |

| Φ2.2×12 | 14-30 | 4.8 | 22 | ZQ65 | 33 |

| Φ2.2×14 | 20-30 | 4.8 | 30 | ZQ65 | 36 |

| Φ2.2×16 | 25-35 | 4.8 | 37 | ZQ65 | 39 |

| Φ2.4×18 | 38-45 | 4.6 | 45 | ZL85 | 45 |

| Φ2.4×20 | 40-50 | 4.6 | 45 | ZL85 | 47 |

| Φ2.2×2 | 45-55 | 4.6 | 55 | ZL85 | 52 |

| Φ2.6×20 | 50-55 | 4.5 | 55 | ZL85 | 56 |

| Φ3.0×20 | 50-60 | 4.23 | 90 | ZL100 | 78 |

| Φ3.0×25 | 50-65 | 4.23 | 110 | ZL100 | 90 |

| Φ3.2×25 | 55-70 | 3.9 | 110 | ZL115 | 102 |

| Φ3.6×28 | 75-120 | 3.6 | 200 | ZSY500 | 125 |

Order notice:Please indicate the type of transmission.

| Packaging Detail:to customer requirement |

| Delivery Detail:30 days |