Fiber cement board panel machine line

| Condition:New | Application:building | Automatic Grade:Automatic | Production Capacity:100 |

| Place of Origin:Jiangsu China (Mainland) | Brand Name:CX | Model Number:CX1200 | Voltage:380 |

| Power(W):70KW | Dimension(L*W*H):31M | Weight:20T | Certification:CE |

| Warranty:1 YEAR | After-sales Service Provided:Engineers available to service machinery overseas |

Project Feature:

1. The source of the production raw materials is widely with no regional restriction. The product is made of sawdust, straw (rice hulls), many kinds of crop straw and inorganic material (such as talcum powder, infusorial earth and powder coal ash) after special technology. So this project have low production cost, small investment and fast effectiveness.

2. The equipment has high automatic degree, simple production technology, low labor intensity and production line, and there is no noise and three-wastes (waste water, waste gas and waste residue) during production.

3. Low production energy consumption. With the influence of chemical reaction, it can meet the requirements about production technology without high temperature and high pressure.

4. can produce according to different customers' request like size(length* width*thickness) , material .

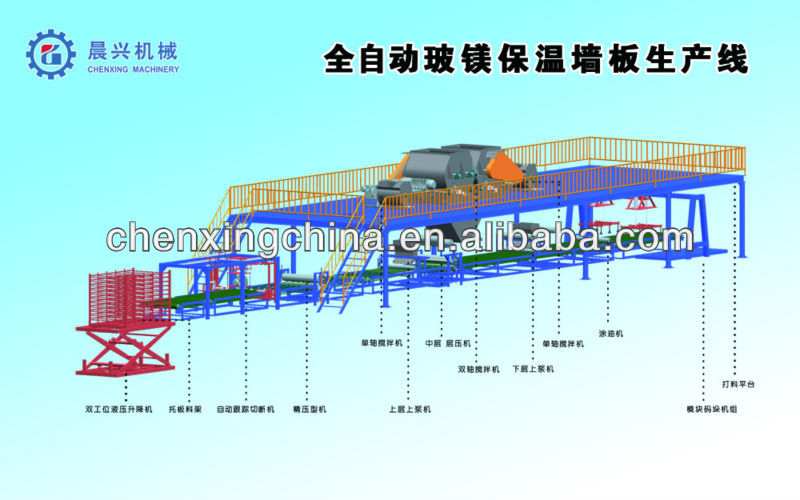

Automatic fiber cement board produce machine

Making spec:1Glass magnesium board

2The fiber cement board

:Can be adjustable

Process Flow Chart

Hoist top material-Material Matching-Discharge mixing-Put mould plate and transport-Lay plastic film-Lay bottom material-Lay fiberglass Mesh-Discharge middle material-Lay fiberglass mesh-Lay top material-Rolling compound-Making panel-Scaletracing and cutting-Transport Semifinished panel-Auto stacker received panel and send to shelf-3T forklift transport-Store up and maintain

| Packaging Detail:WOOD |

| Delivery Detail:70 DAYS |