factory New patented advantage rotary drum dryer---your best choise

| Condition:New | Type:Drum Drying Equipment | Place of Origin:China (Mainland) | Brand Name:Wanqi |

| Model Number:HGJ-2000 | Voltage:380V | Power(W):30 kw | Dimension(L*W*H):18*3.62*3.57 m |

| Weight:30 t | Certification:CE ISO | Warranty:2 year | After-sales Service Provided:Engineers available to service machinery overseas |

New patented advantage rotary drum dryer---your best choise

dryerIntroduction of rotary drum dryer

Beer Factory a large number of deputy products in the yield the largest is wet beer bad, but wet Lees easy metamorphic, therefore in transport and storage in the easy pollution environment.

- In recent years, a lot of beer factory start to beer deputy products processing, this both can be reduce environmental pollution, and can increase economic benefits.

- Beer bad drying machine can be fast will water content in 85 about wet beer bad after dehydration, and drying to water content in 10 about do products.

- The current The set of device has in domestic more than beer enterprise, and feed processing enterprise into use, and create considerable economic benefits.

- Drumdryingmachineisalso widelyusedforstrawbriquettefuel,machinery,woodPelletFuel,sawdustbriquettecharcoal,agriculturalengineeringand otherindustries.

- Drum drying machinecandry for corn straw, soybean straw, cotton straw, wheat straw,Sorghumstalk, wood chips, shavings and sawdust,mulberryleaves,Ginkgo bilobaleafand other agricultural cellulose materials.

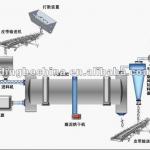

Working principle

Feeding and discharging unit is installed with thermocouple to control drier temperature. The temperature change of drier's feeding end can be indicated by the thermometer to control the inner drier temperature ( generally 250-350°C)

Rotary drier apply new scatter plate device,it can guide direction, flow on an average and scatter the material.which is adopts direct flow type of heating with heat soure from firing unit.

The material to be dried is pushed back immindiately by spiral board when enters the shell from feeding tank and feeding chute. Because the drier is installed in slope, material flows to the back end under gravity and rotation force, meanwhile, it is lifted by board repeatedly and thrown down accordingly, which make the material form even curtain, and exchange heat sufficiently with inner the heat flow.In the end, water in the material is dried by repeatedly scattering.

Techinical Parameter of Rotary Dryer

| Type | Output (t/h) | Power (kw) | Size (m) | Weight (t) | ||

| HGJ-600 | 0.6 | 5.5 | 6.0 | 1.4 | 1.7 | 3.00 |

| HKJ-800 | 0.8 | 7.5 | 8.0 | 1.6 | 1.8 | 4.50 |

| HKJ-1000 | 1.0 | 11.0 | 10.0 | 1.9 | 2.1 | 6.00 |

| HKJ-1200 | 2.0 | 15.0 | 12.0 | 2.2 | 2.4 | 12.00 |

| HKJ-1500 | 4.0 | 18.5 | 14.0 | 2.655 | 2.895 | 18.33 |

| HKJ-1800 | 8.0 | 22.0 | 16.0 | 3.06 | 2.98 | 21.50 |

| HKJ-2000 | 13.0 | 22.0 | 16.0 | 3.62 | 3.57 | 30.00 |

| HKJ-2200 | 17.0 | 30.0 | 18.0 | 3.62 | 3.57 | 34.15 |

| HKJ-2400 | 20.0 | 30.0 | 18.0 | 3.86 | 3.76 | 39.90 |

| HKJ-2600 | 27.0 | 45.0 | 20.0 | 3.86 | 3.76 | 55.00 |

| HKJ-2800 | 33.0 | 55.0 | 20.0 | 3.86 | 3.76 | 70.00 |

| HKJ-3000 | 42.0 | 75.0 | 20.0 | 5.0 | 4.5 | 110.00 |

| Packaging Detail:as request |

| Delivery Detail:20 day |