Factory direct sale price coal/charcoal/ coke briquette production line

| Type:Briquette Machines | Condition:New | Motor Type:AC Motor | Place of Origin:Henan China (Mainland) |

| Brand Name:E.P | Model Number:HSYQ-500 | Certification:CE | Warranty:12 months |

| After-sales Service Provided:Overseas third-party support available | power:30-37kw | capacity:6-8ton/h | applicable material:coal, charcoal, iron, limestone, fireclay and other mineral powders |

| size feeding material:5mm or below | moisture of raw material:8-12% | rollers diameter & width:500mm*300mm | pressure type:double rollers squeezing |

| maximum pressure:10 ton | delivery time:within 15 working days | package size:3*2.2*2.4 |

Factory direct sale pricecoal/charcoal/cokebriquetteproduction line

High efficiencies of mineral briquette production line:

The briquette production line usually needs to provide two or three blenders to meet the capacity of feeding material, due to high efficiency of mineral briquette machine.

The other high efficiency: the applicable material is very wide, such as iron powder, coal powder, charcoal powder, coke powder, many kinds of ferrous and non-ferrous metal ores, fireclay material, and other industrial tailing wastes. All of these materials could be compress into briquettes.

The main processes of mineral briquette production line:

- crushing: to ensure the size of raw material, because of the requirement of raw materials size,5mmor below.

- drying process: to dry materials moisture(8-12%),in order to keep raw material ready for making briquettes.

- mixing/blending part: the first mixing part is to mix the raw material together with binder completely. And the second mixing part is to ensure the materials feed into briquette machine evenly, in other words to control the whole production line’s capacity.

- pre-pressing procedure: to increase the final briquettes density and forming ratio.

- briquette making process: convert the pre-pressed raw material into briquettes, and make sure the strength and density.

- final briquettes drying part: you can use the vertical dryer or box dryer to reduce the briquettes moisture, and then the final products could be easy to store.

The key part of this whole line is the briquette making process. The briquette machine could press mixed material (raw material, binder and liquid) into briquettes with powerful pressure. As for the small density material, the briquette machine mostly is equipped with screw forced feeder and hydraulic system to ensure the feeding materials capacity, and then to increase the capacity finally. Therefore, our briquettes haveTHREE HIGHfeatures:high density, high strength and high forming ratio.

Advantages of this complete mineral briquette production line:

·Chinamanufacturer

·professional technical team for reasonable design & suggestion

·Powerful 24 hours technical supporting

·Rollers with good anti-abrasive material to enlarge the service time.

Flow chart of mineral briquette production line:

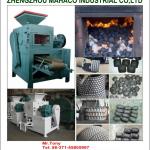

Pictures of machines in each process:

Final briquettes:

Note: please tell me about your raw material, I will offer you more details and information. Thank you!

More information or any request, you can contact me via following ways:

| Packaging Detail:standard ocean shipping plywood case |

| Delivery Detail:within 15 working days |