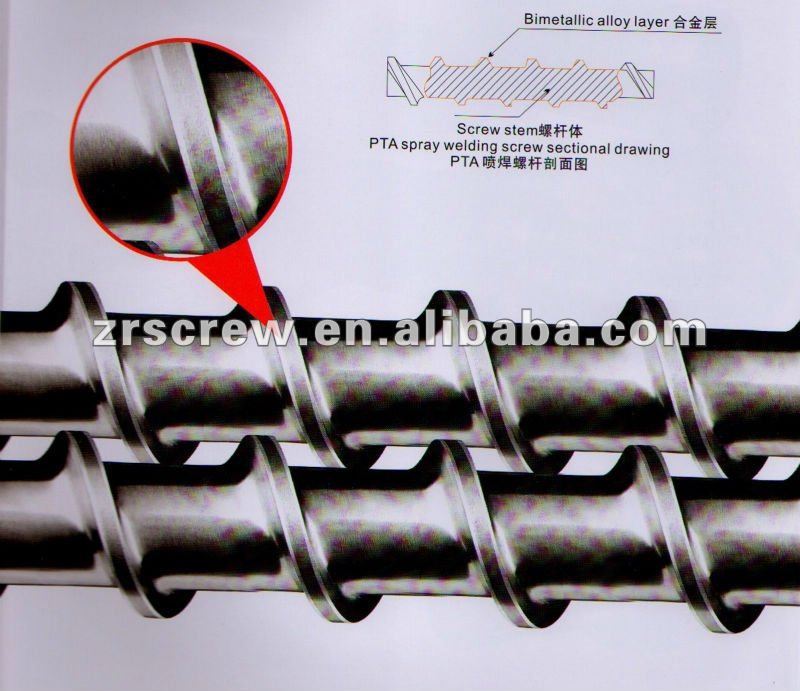

extruder machine bimetallic screw barrel

1.38 CrMoALA Material, 2.Nitriding Depth:0.5~0.7mm, 3.High Quliaty Base Material, 4.Bimetallic Twin Screw Barrel - details see: https://www.machineto.com/extruder-machine-bimetallic-screw-barrel-10334576

| Place of Origin:Zhejiang China (Mainland) | Brand Name:LiJing | Steel Material:38CrMoAlA;42CrMoV;Cr12MoV;4Cr5MoSIV | Screw Diameter:15mm- 300mm |

| Technology:nitriding treatment, alloy coating spraying, heat-treatment | Technical Index:30g-25000g | Appliance:PP, PE, PA, PVC, PC, ABS, AS etc | Depth of Nitrated Layer:0.6-0.8mm |

| Hardness of nitration:900-1020Hv | Thickness of Cr-coating Layer:0.03-0.08mm |

extruder machine bimetallic screw barrel

Our parallel twin screw and barrel have high surface area and low shear screw designs that will optimize the melt homogeneity.

1.Parallel Twin Screw and Barrel Ranges for Parallel Twin-screw Extruder:

| Screw Diameter | 50mm-180mm |

| Screw Length | L/D ratio 16 - 35 |

2.Technology:nitriding treatment ,alloy coating spraying, heat-treatment applied

3. Technical parameter:

| Material | 38CrMoAIA,42CrMo,alloy powder |

| Nitridedepth | 0.7mm |

| Surface hardness | HV950 - HV1,020 |

| Fragility of nitrition | less than grade 1 |

| Screw straight tolerance | 0.015 mm/m |

| Surface roughness | Ra 0.4μm |

| Linearity of the screw | 0.015mm |

| Depth of double alloys | > 2ram |

| Bimetallic layer depth | 3mm |

| Packaging Detail:Wooden case. |

| Delivery Detail:30 days after order confirmed |