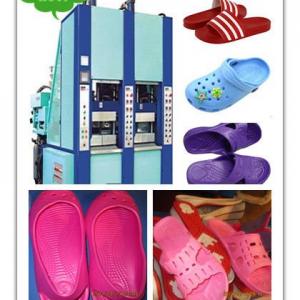

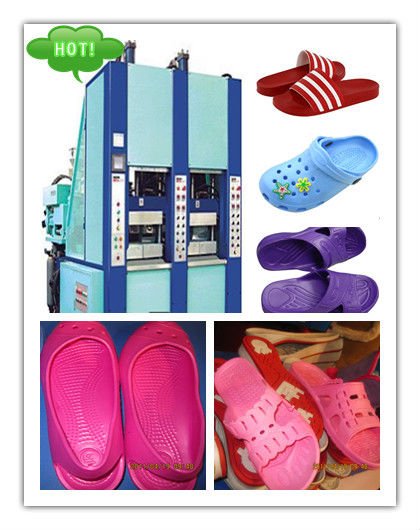

EVA slippers machine(EVA shoe Machine,EVA Machine)

| Place of Origin:Zhejiang China (Mainland) | Brand Name:JG | Model Number:/ | feature:Simple operation |

| price:factory price | delivery:soon delivery | advantage:high quality and reliability | auto/by hand:auto |

| supply:bulk supply | design:customer design can be done | use:uesd for shoes | warraty:1 year |

| name1:EVA shoe machine |

EVA slippers machine(EVA shoe Machine,EVA Machine)

This machine produces arrange of products including EVA slippers, sandals, clogs, mid-sole, sport protectors and various kinds of shoes and shoe accessories all depends on the EVA shoe mould and can also make EVA wheel for toys and so on.

Features

1:uesd forshoes

2Simpleoperation

3:bulksupply

4:factory price,

5:soon delivery

6:sample available

7:customer design can be done

8.high quality and reliability

9.auto/by hand

10.convenient maintenance

Characteristics:

1. Less exhaust gas, less waste water, lowness noise.

2. Big caliber cooling system, prevent blockage & encrustation, circulation liquid can use general main water, dispense with adding industry additive and dispense with softening water.

3. Full close station with few or none thermal radiation, such design can protect operator health.

4. Extensiveness adopting vacuum and pneumatic system, adopting oil less bearing to maximum reduces environmental pollution because of the oil way & lubricating system.

5. Full computer control, humanized man-machine interface, and easy operation.

6. It saves energy and increases efficiency.

7. It has larger injection capacity and clamping force

8. The rotation of workstation is characterized by continuously variable speed, lower noise and steady.

9. Preparing device and injection device are controlled proportionally, besides, the speed; material capacity and pressure are adjustable, which ensures the quality of products.

10. It is applied to manufacturing single color and double color, and can free to choose work station to

different requirements of production

USE:

1. Extra large design of die holder, can produce 4pairs/station in he same time,which increasing the productivity a lot.

3. the injection oil hydraulic system adopts the proportional flow, pressure control valve.

4. The injection part controlled by 5 stage PID, can achieve the setting temperature fast and steadily to insure the high quality of finished products.

5. It adopts the function of auto diagnosis and maintain to operate the monitor system, and insure you know the machines working condition.

| Work Stations Clamping Force (kg) Mould-Opening Stroke (mm) Standard Thickness of Mould (mm) Mould Plate Size (mm) Height of Injection Nozzle (mm) Method of Heating Heating Power (kw) Diameter of Screw (mm) L/D Ratio of Screw Max Injection Capacity (cc) Injection Pressure Injection Speed (cm/sec) Rotating Speed of Screw (r.p.m) Temperature Control (section) Heater Barrel (kw) Motor for Injector Moving (kw) Heating Board of Mould (kw) Hydraulic System (kw)(50hz) Vacuum Pump (kw) Cooling Fan of Barrel (HP) Total Electricity (kw) OilTank Size (L) Machine Weight (kg) Output ( Pairs/day) | 6 150000 350 100-210 2(290*550) 60 electric 8.04 60 23 860 1100 10 0-190 4 12.1 1.5 76.8 40.5 2.2 1 150 1000 23800 8000-10000 |

| Packaging Detail:all is packed in the PET film case. |

| Delivery Detail:within 25 days |