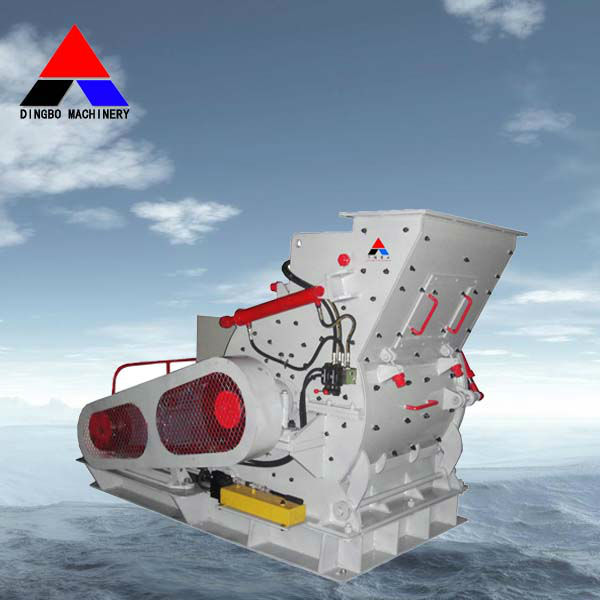

European version of rough grinding machine for iron ore,stone and slag

| Condition:New | Type:Universal | CNC or Not:CNC | Place of Origin:Shanghai China (Mainland) |

| Brand Name:DingBo | Model Number:PC4015-132 | Power(W):110-132kw | Dimension(L*W*H):3720X2650X2540 |

| Certification:ISO,CE | After-sales Service Provided:Engineers available to service machinery overseas | Name:European version of rough grinding machine for iron ore,stone and slag | Rotor diameter:1150mm |

| Rotor speed:550-800r/min | Rotor length:1500mm | Feed head size:500X1500mm | Max feed size:<100mm |

| Finenness:0-8mm | The number of hammer:32 | Processing:60-100t/h |

European version of rough grinding machine for iron ore stone and slag

ProductDescription

Dingbo European version of rough grinding (also Coarse Powder Mill ) is widely used in metallurgy, mining, chemical,cement coal ,dry stone, construction, sand, refractories and ceramic industrial and mining enterprises, engaged in breaking and crushing the material in the operation. It is mainly suitable for crushing compression strength not higher than 320MPa of various soft and hard ore. Hammer Crusher (Coarse Powder Mill )is a kind of new high-tech mill machine to meet the requirements of coarse powder processing customers. The Hammer Crusher or Coarse Powder Grinding Mill is developed based on our experts' rich experience in the milling industry and considering recommendations and requirements of domestic and foreign clients. It is the ideal equipment to replace Raymond Mill, ball mill, and other traditional mill which only process fine powder materials. It is high-efficiency equipment and widely applied in quartz sand, silica sand, foundry sand, fine sand and other sand abrasive industry. By being a component of closed production lines, it can produce various size products of better effect.

Advantages and Features

1.The production capacity, high crushing ratio;

2.Low power consumption, uniform particle size;

3.Mechanical structure is simple, compact and lightweight;

4.Low investment costs, management, and convenient

Structure and Working Principle

The Hammer Crusher or Coarse Powder Mill mainly by coarse gringing casing, rotor, bearing the hammer and the grate bars and other components. Upper and lower case in two parts, welded together by a steel plate after cutting, the remaining parts bolted into one. Set with high manganese steel liner inside the case, to facilitate replacement of worn; its array of rules installed on the spindle distribution of the hammer, hammer and rotary table and through the rotor shaft formed. Host through the motor, V-belt driven spindle, so that the rotor rotates, hammer by the centrifugal force generated by rotation around the stretch to bulk materials from the feed inlet into the crushing chamber, the high-speed movement of the hammer will be crushed. Broken by passing the material under.

Main Technical Parameters

| Packaging Detail:The products should be processed to be rustproof and moisture proof before delivery. The small parts are packed into wooden crates; the big parts are wrapped by plastic sheeting |

| Delivery Detail:25 days |