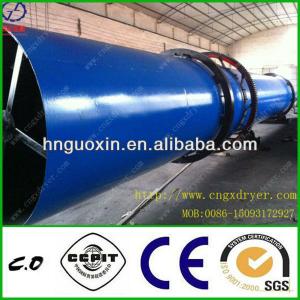

Environmental Friendly No Dust Coal Rotary Dryer

| Condition:New | Type:Rotary Drying Equipment | Place of Origin:Henan China (Mainland) | Brand Name:Guoxin |

| Model Number:GX-2.4x22m | Voltage:380V | Power(W):37kw | Dimension(L*W*H):22m*2.4m(length*diameter) |

| Weight:48.6 ton | Certification:CE, OEM, ISO | Warranty:1 year | After-sales Service Provided:Engineers available to service machinery overseas |

| Capacity:1-26t/h | Spare parts:lifelong supplier | Coal rotary dryer Color:any color is available | Heat source:diesel, gas, coal, electricity |

| Installation:seller guide | Dimension:depend on materials, capability |

Guoxin Coal Rotary Dryer for drying wide humidity materials

Operating usnder high temperature and low oxgen to avoid material being self-burning or charring when drying. Guoxin coal rotary dryer has good sealing performance, saving energy.

I. The compositions of coal rotary dryer

1. Dryer cylinder 2. Roller ring 3. Big gear 4. Small gear 5. Carrier roller 6. Bearing box 7. Roller carrier shaft 8. Cushion block of roller ring 9. spring plate 10. Transmission shaft 11.Reducer 12.Transmission pedestal 13. Coupler 14. feeding device 15. discharging device 16.Motor 17.Pedestal of carrier roller 18.Bearings 19.Cyclone 20.Fan

II. Techincal Parameter of coal rotary dryer

| Model | Reducer Model | Reducer Ratio | Speed (r/min) | Capacity (t/h) | Power (KW) | Weight (ton) |

| Φ 0.8x10 | JZQ450-16-II | 7.2 | 0.8-2.2 | 4 | 5.1 | |

| Φ 1.0x10 | JZQ450-16-II | 6.73 | 1-3.8 | 5.5 | 7.5 | |

| Φ 1.2x12 | ZL50-16-I | 5.8 | 1.8-5.5 | 11 | 13.8 | |

| Φ 1.5x12 | JZQ5000-III-2F | 16.46 | 4.8 | 4-9 | 15 | 22.3 |

| Φ 1.5x16 | ZQ50-16II-2 | 16.46 | 4.8 | 4-10 | 18.5 | 28.8 |

| Φ 1.8x16 | JZQ650-III | 18.84 | 3.2 | 6-12 | 22 | 39.8 |

| Φ 2.0x18 | JZQ650-III | 31.5 | 3 | 10-20 | 30 | 40.5 |

| Φ 2.2x20 | JZQ750-III | 31.5 | 3 | 10-25 | 37 | 48.3 |

III. Working Principle of coal rotary dryer

- Under normal conditions, the wet material is clotty coal. If so those clotty coal should be crushed by double-shaft mixer before sending dryer. Just like the picture in following.

- Along with the rotation of coal slurry dryer, wet coal will throughly making contact with hot-air, thus humidity inside of wet coal will be evaporated.

- Under the action of gravity, dried coal will move into the discharged hole because the coal rotary dryer is installed with 3-5 degree tilt angle. The temperature output coal is around 70-80 centigrade.

IV. The Maintenance Method for Coal Rotary Dryer

- With reach coal rotary dryer manufacture experience, Guoxin will offer you professional after-sale service. Expecially maintenance is important factor during machine running.

- Bearing is a part of equipment which take full weight of dryer, the choice of tube have a great influence on service life and rotation rate. So it would be better if we can sure it's clear and with good sealing performance.

- Finally, it's cleaning dryer's inner structure regularly. Because the wet material with high moisture easily stick upon the wall of drum, if we don't clearn it regularly, it will be clogging in the dryer. So cleaning method is running dryer without wet materials, thus those sticky material will be dried and out off drum wall, as the same time, rapping on a barrel wall of dryer in the rules.

V. Successful Case for Coal Rotary dryer

VII. Impeccable After-sale Service for Coal Rotary Dryer

- Before everything, we should talk about the raw material, its moisture, capacity you need, matters need attention during drying

- Suggesting you suitable coal rotary dryer, diameters:1.5m, 1.8m, 2.0m, 2.2m etc, and making sure the width and length of coal rotary dryer

- Solving all of your questions, whether technology, shipping, installation or operation.

- Training technical personnel for customers

- When the mesh belt dryer is shipped to working-site, our engineer will offer guidance for installing and debuging equipments.

| Packaging Detail:4GP containers, or as your requirements |

| Delivery Detail:IN STOCK Within 18 working days after receiving 30% prepayment |