ECO-BRICK production line based on high pressure brick making machine.

| Type:Hollow Block Making Machine | Brick Raw Material:Fly Ash | Processing:Brick Production Line | Method:Hydraulic Pressure |

| Automatic:Yes | Capacity:6000 per hour | Place of Origin:Fujian China (Mainland) | Brand Name:Titan Machinery |

| Model Number:ECO-BRICK | Power:150 KW |

Our company in cooperation with european scientific-research universities and chinese brick making factories developed unique technology which makes it possible to usefly ash with high content of CaOas raw materialsfor extremely cheap bricks.

The main difference of our technology is that we do not use any binding materials except CaO which is already inside fly ash.We also usually do not add any gypsum and other additives.

You use only industrial waste - fly ash which generates in big quantities from electric power generation plants.

The quality of the bricks which we receive from such a fly ash is very good.

Strength for the bricks. According to our testes bricks which we receive using our technology withstand 3000-4000 P.S.I. which is equivalent to Class 3-Class 4 (* Based on British Standard 3921:1965).

Freeze-thawing resistance more than 50 cycles.

Water absorption - less than 5%.

Coefficient of softening - 0,9 (higher than for normal sand-lime brick).

During developing of the technology our research team solved many serious problems:

1. Usually fly ash has small amount of big particles for structure-forming of the brick. We found that fly ash from different electric power plants has particles with the size which is less than 0,63 mm.

2. Lime (CaO) inside fly ash in contrary has size bigger than we hope to have for the fast slaking of lime. There we impossible to use such a lime as binding material if we do not make lime slaking time smaller. We found a way how to decrease the size of the lime particles without making structure-forming parts of the fly ash smaller. We are using patented-design activation machine for destruction of lime particles.

At the picture below you can see the inner structure of the bricks which were produced without activation and you can clearly see big particles of lime inside.

3. Bricks if we don't use activation quickly desintegrate even after only 4 freeze-thawing cycles.

4. Overall dimensions of the bricks without activation swelled during autoclaving and it was among the primary cases for quick desintegration.

Picture of the inner structure of the brick after the activation process.

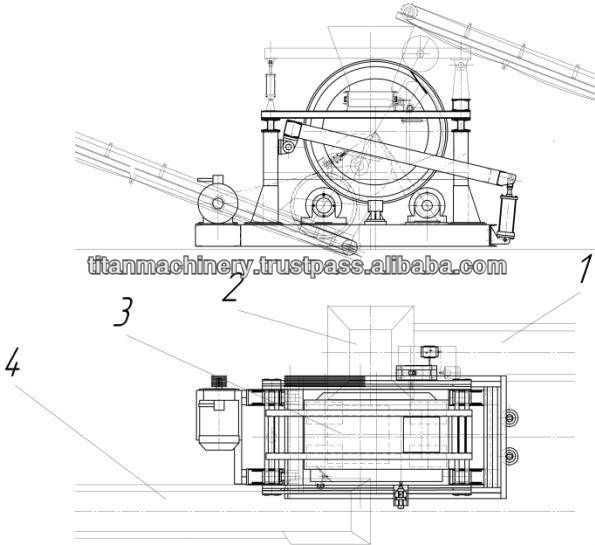

We are usingdouble-action hydraulic high pressure brick making machinesfor compaction of the bricks with automatic pneumatic cubers. Such a solution helps save big amounts on pallets investment and makes all production process simpler and more reliable.

The overall process workflow is similar to what shown at the picture below:

Industrial waste recycling is the very big problem worldwideand billions of tons of fly ash generated every year which means that finding proper solution for this problem is very urgent.

We can turn the fly ash from the waste status into valuable resource which will help you to produce high quality bricks almost free of charge.

Last time there was a worldwide trand for using cleaner energy sources and decreasing CO2 emissions. Due to we do not using any outside binding materials we can say that our brick is almost zero-CO2 product. It is really green technology due to we not only producing high quality bricks but also preventing atmospheric air pollution (using limestone for sulphurocatching) and we prevent fly ash dumping.

As to the bricks production process - we can say that we achieving green product due to we do not spend energy on producing binding materials like portland cement or quick lime. If electric power plants will install our fly ash brick making machines close to their generating facilities they will be able to use cheap steam for autoclaves which will make all process even more economically efficient.

Our technology makes it possible to make coal burning electric generation far more environmental-friendly than ever before.

Almost all modern electric power generation plants using now milled limestone sulphurocatching, limestone can be a good source of CaO in fly ash. Brown coals (lignite) fly ash also good source of CaO.

Our solution is really unique at the present-time market due to we can provide real turn-key solution based on proven results and reliable equipment.

We also wanted to emphasize you attention to the fact that we providing research services and we can check your raw materials and modify whole production process according to chemical and physical features of your fly ash.

Our company uses 3E+I approach to all our development processes which means - ECONOMY, ECOLOGY, EFFICIENCY and INNOVATIONS.

| Packaging Detail:sea containers |

| Delivery Detail:100 days |