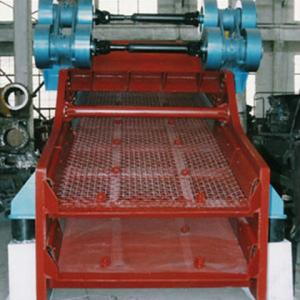

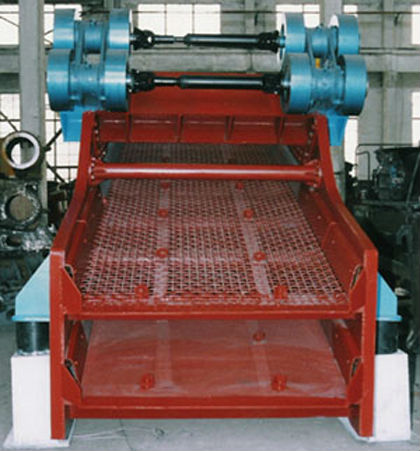

DZSF high efficient motor vibrating screen/vibration screen

| Condition:New | Place of Origin:Shandong China (Mainland) | Brand Name:huaxin | Model Number:DZSF |

| certification:ISO9001:2008 | application:sand, makeing,Mining, Cement Industry... | Mesh size:5-100mm | Capacity:50-475m3/h |

Introduction of circular vibrating screen:

Mining machinery ,Circular vibrating screen is one of the unique product or equipment, it is used for separating the stuff. The circular vibrating screens work on circular motion. The vibrating screens are mainly used in coal dressing, metallurgy, mine, power station, water conservancy project, building industry, light industry and chemical industry etc They are efficient screening machines for the classification of bulk material such as coal, minerals, coke etc

Series circular vibration screen is based on the Germany's USK series vibration screen, and re-created and improved by us.according to the sighificant amount of research and many years' design, production and application experience in China. It is applies to industries of coal, power, mining ,building material, chemical and other industries.

circular Vibrating Screen Features and Benefits:

(1)Simple and dependable Eccentric type system.

(2)High screening capacity.

(3)High durability.

(4)No transmission of screen panels.

(5)Ready changing of screen plates.

(6)Rigid and vibrating resistance screen body.

(7)Multi-layer screening layers to get the different size products

(8)Adjustable amplitude to control the speed and product particle size and uniformity

(9)Long screening area can achieve high capacity

(10)Adopts tire coupling and soft connection makes operation smooth

(11)Fully closed structure without dust pollution;

(12)Both used in dry and water washing wet screening

Work Principle of Mining machinery , circular Vibrating Screen:

circular Vibrating screens is compiled of mainframe, eccentric bock, screen web, rub spring, electric motor, coupler and some more. Vibrating Screen moves round. It has multi-layers and is of high efficiency. The eccentric shaft vibration exciter and partial block help to adjust amplitude. The material drops down along the long line.

We have always kept in our minds the choices, preferences and the tastes of our all clients. We will offer you suitable type according to your requirements.

Daily Maintenance of circular vibrating screen:

1. Before running:

(1) check coarse mesh and fine mesh if there is a damage.

(2) make sure that each group clamps are locked.

2.When running:

(1)pay attention to any abnormal noises

(2)keep electric current stable.

(3)keep an eye on abnormal vibration.

3. After running:

(1)clean up the vibration every time

(2)inspect regularly the coarse mesh , fine mesh and the spring if there are fatigue and damage.

(3)check whether any part of the vibrating body is damaged due to vibration.

(4)add lubricating oil if needed.

Our products

our company

| Packaging Detail:standard container or as your requirement |

| Delivery Detail:10-20days after received your payment |