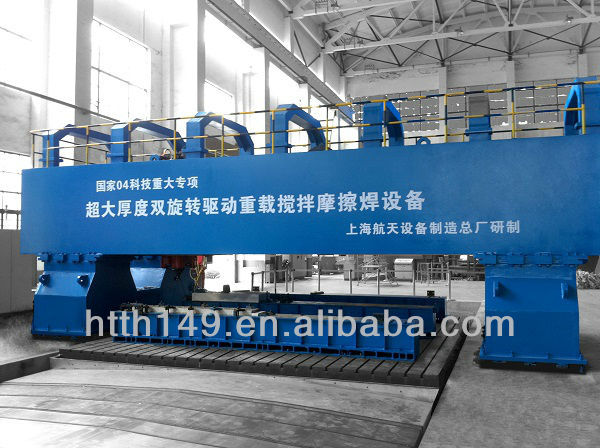

Dual Rotation Heavy-load Friction Stir Welding Equipment

| Type:Other | Place of Origin:Shanghai China (Mainland) | Brand Name:CASC | Model Number:HT-JM80*63/3 |

| Voltage:380V | Dimensions:13500mm*9000mm*4500mm | Usage:Friction Stir Welding | Certification:GJB9001B-2009 Quality Certification |

| After-sales Service Provided:Engineers available to service machinery overseas | Structural Type:Double Gantry Structure | Max Thickness:80mm | X-axis(Traverse):0-6300mm |

| Y-axis(Cross):0-6000mm | Z-axis(plunge):0-500mm | Table Size:6000mm*5000mm | Control System:5-axis CNC System of Parallel Mechanism |

| X-axis speed:5-1500mm/min | Y-axis speed:5-1500mm/min | Z-axis speed:5-350mm/min |

Specification:

| Model | HT-JM80*63/3 | ||

| Structural Type | Double Gantry Structure | X-axis speed | 5-1500mm/min |

| Max Thickness | 80mm | Y-axis speed | 5-1500mm/min |

| X(Traverse) | 0-6300mm | Z-axis speed | 5-350mm/min |

| Y(Cross) | 0-6000mm | C axis | n*360°CNC |

| Z(Plunge) | 0-500mm | A axis adjustment | 0~5°Manual |

| Machine size | 13500mm×9000mm×4500mm | Control System | 5-axis CNC System of Parallel Mechanism |

| Table size | 6000mm×5000mm | ||

Equipment Features:

1. The equipment is used for linear and curved welding of aluminum alloy plates with welding length ≤6300mm,Its single-sided welding thickness ranges from 2 to 80mm, and double-sided welding thickness ranges from 2 to 150mm;

2. 5-axis CNC Technology of Parallel Mechanism is used in FSW equipment for the first time in China, which realizing continuous curved weld with high conformity;

3. Thermal field control is used to guarantee consistency of weld structure and conformity of mechanical property;

4, Adaptive control of constant pressure is used to guarantee weld quality;

5. Mechanical compaction mechanism is used to reduce joint misalignment and effectively control weld deformation;

6. Real-time monitoring of welding procedure and data recording are fulfilled.

| Packaging Detail:International transport standard |

| Delivery Detail:6 months |