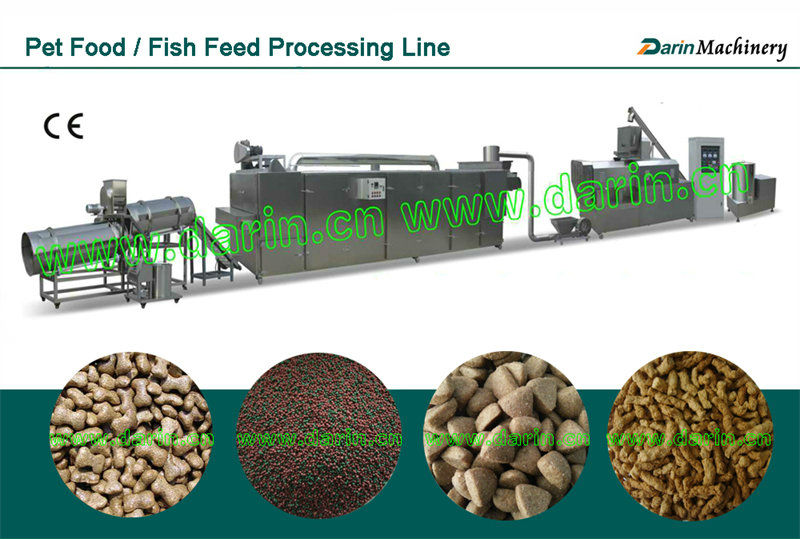

Dry Pet Food Processing Line With CE

| Condition:New | Place of Origin:Shandong China (Mainland) | Brand Name:DARIN | Model Number:DR series |

| Application:Dog | Voltage:380v | Power(W):80kw | Dimension(L*W*H):18*5*3m |

| Certification:CE | Warranty:12 months | After-sales Service Provided:Engineers available to service machinery overseas | Spare parts:1 set |

| After-sales service:Full life | Output:120-150kg/hr | Processing type:Extrusion | Moulds:6 free moulds |

| Material:Stainless steel 304 | Commissioning:Provided |

Introduction

Pet food Processing Line focuses on the production of feeds for animals with a high emotional value but low economic usefulness, apart from the aspect of breeding.

Samples

Dog and cat foods, directly extruded and dried, dry or semi-moist. These constitute the biggest market segment.

Feed for fish, high-grade complete feeds capable of maintaining the health even of exotic species in aquariums over prolonged periods of time, sinking or floating feed.

Features

Nonetheless, balancing the components and gentle processing are at the center of the related quality considerations.

Extrusion is therefore increasingly proving to be the right tool for modern Pet food.

A complete feed, fed as a diet over a prolonged period of time, must ensure the vitality of the animal and prevent deficiencies.

This is quite a challenge to the feed manufacturer in terms of the selection and composition of the raw materials, their optimal processing, and effective quality assurance.

A large number of pet food products are made by extrusion.

Key Equipment Show

Technical Parameters

| Model | DR-65 | DR-70 | DR-85 | DR-90 |

| Capacity | 120-150kg/hr | 150-300kg/hr | 500-800kg/hr | 800-1000kg/hr |

| Power | 80kw | 90kw | 150kw | 200kw |

| Dimension | 18 x 5 x 3m | 20 x 5 x 3m | 35 x 5 x 3m | 40 x 5 x 3m |

Commissioning & After-sales Service

1. We make accurate factory layout design according to customer’s factory size; if the customer needed, we could make workshop design with electricity power, water supply, gas power, material storage, final storages, worker’s restroom, etc.

2. After receiving firm order and down payment, we start to apply for the Visa to your country immediately; while the machines arrives your factory, our engineers are ready to start for the commissioning service.

3. 1-2 of our engineers will go to your factory to install and adjust the processing line to realize normal production at shortest time.

4. Our engineers have responsibility to teach the workers how to operate, clean, maintain and repair all the machines, until the workers could well operate the processing line..

5. Our engineers can provide basic formula for the production, and help the customer to produce good quality food according customer’s detailed formula.

6. It normally costs 10-14 days for the commissioning service, and we supply 1 year guarantee from the date of completion of commissioning service.

Delivery

Exhibition Show

| Packaging Detail:Fumigation wooden case, which is suitable for long-distance transportation, multi-time loading & unloading for fork trucks. |

| Delivery Detail:45 days |