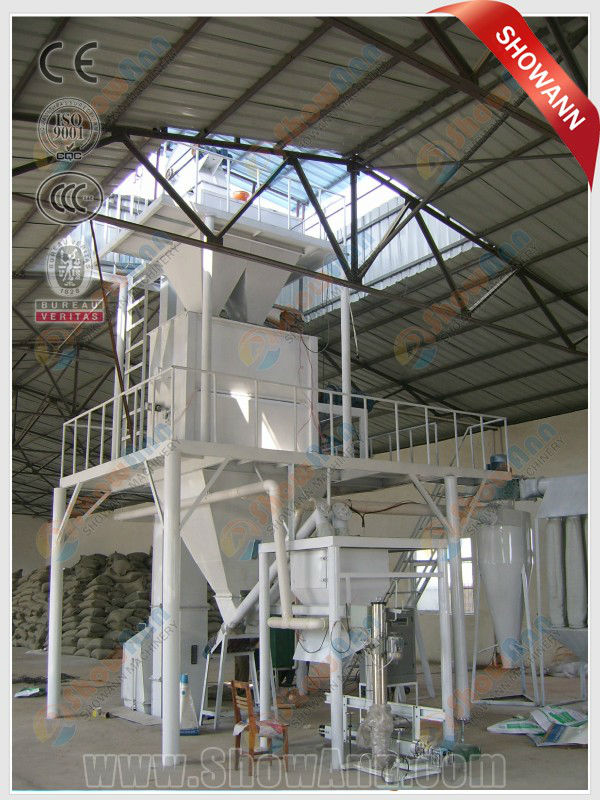

Dry Mixing Mortar Powder Manufacturing Line

| Condition:New | Application:Wall Putty Powder Mixing | Production Capacity:5-8t/h | Place of Origin:Henan China (Mainland) |

| Brand Name:Showann | Model Number:SAC-1 | Voltage:380V, 220V or Customized | Power(W):45KW |

| Dimension(L*W*H):7500*8200*8500mm | Weight:13t | Features:Full automatic | Certification:CE ISO |

| Warranty:One years' warranty | After-sales Service Provided:Engineers available to service machinery overseas | Installation and training:Provide |

Dry mixing Mortar Powder Manufacturing Line

We are the integrated solution supplier of dry mortar production line, provide you quality verified equipment, formula process, raw material of additives, and good after-sales services. Escort for your success!

China new product full automatic dry mortar producing line for mixing cement and sand

Descriptions of full automaticdry mortar producing line:

SAC-1 series full automatic dry mortar producing line is based on the latest design concept in Europe, this production adopts the advanced computer auto-control system, whose production capacity can reach 30-100 thousand tons per year depend on the system configuration. The production line consists of storage system, metering and batching system, conveying system, mixing system, air compressor system , packaging system, and dedusting system, etc

Working principle full automaticdry mortar producing line:

According to requirements of the customers, the system can be equipped with 3-6 bulk storage bins, the material in which will, after being processed by the metering and batching system, be conveyed to pending-for-mixing bin, and then fed into the high-efficiency biaxial agravic mixer for continuous mixing. The finished product in conformity with mixing accuracy requirements can be sent to the finished products bin shortly after mixed. Moreover, there is design with automatic rationing and packaging machine at the bottom of finished products bin, allowing for synchronous auto-packaging operation. Featured with easy and convenient operation, high efficiency, it can both obviously reduce labor intensity and effectively reduce dust pollution.

Application of full automatic dry mortar producing line:

Full atuomatic dry mortar producing line can manufacture the following various mortars:

1) Masonry mortar

2) Thin and smooth wall mortar

3) Hand-plastering screeding mortar

4) Colored coating mortar

5) Water-proofing mortar

6) Plaster powder

7) Wall plastering mortar

8) Ceramic tile adhesive mortar

9) Self-leveling mortar

10) Heat-preservation mortar

11) Tile grout

12) Gap filler

13) Repairing mortar

14) Putty powder

Technical parameters of full automaticdry mortar producing line:

| Model | Out put | Occupied area | Equipment height | Batching and packaging |

| Simple type | 3-4t/h | 20m2 | 3-4m | Manual batching Automatic packaging |

| Semi-automatic type | 5-8t/h | 50-60m2 | 6-7m | Manual batching Automatic packaging |

| Full automatic type | 8-30t/h | 60-65m2 | 7-8m | Automatic batching Automatic packaging |

Full automatic dry mixed motar production line in factory :

Flow chart of full automatic dry mixed mortar production line:

Main configuration of full automatic dry mixed mortar production line:

Components and parts of full automatic dry mixed mortar production line

Foreign clients in factory:

Full automatic dry mixed mortar production line export:

Several types of products:

| Packaging Detail:Standard export packaging |

| Delivery Detail:10-15 days after receving the deposit |