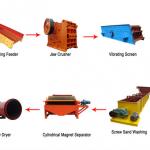

dry magnetic drum separator / magnetic separator machine / magnet separator

| Condition:New | Type:Magnetic Separator,wet | Production Capacity:40-60t/h | Place of Origin:Shanghai China (Mainland) |

| Brand Name:shanghai minggong | Model Number:CTS918 | Voltage:--- | Power(W):1.5kw |

| Dimension(L*W*H):many models | Weight:many models,1445t | Certification:ISO,CE | Warranty:oneyear |

| After-sales Service Provided:Engineers available to service machinery overseas | certificate:ISO | key word:Drum type ore wet magnetic separator | capacity:10~20tph |

| cylinder dia:600mm | cylinder length:1200mm | rotary speed of cylinder:<35r/min | feeding size:2-0mm |

| power:1.5kw |

dry magnetic drum separator / magnetic separator machine / magnet separator

permanent magnetic separator

permanent magnetic separator

permanent magnetic separator

high gradient magnetic separator

1. Application of Magnetic Separator

1. Magnetic Separator applied in iron selecting, wipe of iron. The magnet's position could raise mini metal powder recovery rate and enhance magnetic ore material recycle rate.

2. Magnetic Separator separate raw materials with different magnetic rigidities. The machine works by using magnetic force and the machine force. are designed to recover ferromagnetic materials. The separators are available in designs and sizes to provide solutions for all applications.

3. Magnetic Separator system of magnetic separator integrates good-quality iron-oxide body materials with rare earth magnetic steel; the average magnetic induction intensity of cylinder surface is 100-600mT. According to the needs of customers, the magnetic separator can be co-current, half-countercurrent, countercurrent, and so on. The magnetic separator has the advantages of simple structure, big processing volume, convenient operation and easy maintenance, etc.

4, Magnetic Separator is applicable for wet mineral separation of such materials as magnetite, pyrrhotine, roasted ore and ilmenite, etc. and it is also applicable for iron removal working of such materials as coal, nonmetal and building materials, etc.

2. Working principle of magnetic separator:

The magnetic separator is characterized by a turbulent magnetic field and high separation factor, advanced structure, light weight, reliable operation and convenient maintenance. The magnetic separator is very suitable for the districts that are short of water so that water resource may be saved and ore dressing coasts may be reduced. It develops a new way for mining and utilization of magnetite. The separator may be driven by diesel engine. It may be used in the districts lacking of electricity. The magnetic separators with different magnetic induction intensities that are used for different minerals may be developed according to user’s specific need besides the existing pattern products. The existing series products may meet the needs of concentrators of large, medium and small-sized mines. We welcome users to come to our company for business contact. Our company has industrial prototypes and may do pilot tests for users.

Main Technical Parameters of Magnetic Separator:

| Model | Shell Dia mm | Shell Length mm | Rotate Speed r/min | Feed Size mm | Capacity t/h | Power Kw |

| CTB6012 | 600 | 1200 | <35 | 2-0 | 10-20 | 1.5 |

| CTB6018 | 600 | 1800 | <35 | 2-0 | 15-30 | 2.2 |

| CTB7518 | 750 | 1800 | <35 | 2-0 | 20-45 | 2.2 |

| CTB9018 | 900 | 1800 | <35 | 3-0 | 40-60 | 3 |

| CTB9021 | 900 | 2100 | <35 | 3-0 | 45-60 | 3 |

| CTB9024 | 900 | 2400 | <28 | 3-0 | 45-70 | 4 |

| CTB1018 | 1050 | 1800 | <20 | 3-0 | 50-75 | 5.5 |

| CTB1021 | 1050 | 2100 | <20 | 3-0 | 50-100 | 5.5 |

| CTB1024 | 1050 | 2400 | <20 | 3-0 | 60-120 | 5.5 |

| CTB1218 | 1200 | 1800 | <18 | 3-0 | 80-140 | 5.5 |

| CTB1224 | 1200 | 2400 | <18 | 3-0 | 85-180 | 7.5 |

| CTB1230 | 1200 | 3000 | <18 | 3-0 | 100-180 | 7.5 |

If you have any question or want to konw more detiles about products , please contract me .

| Packaging Detail:dry magnetic drum separator / magnetic separator machine / magnet separatorpacking with export standand |

| Delivery Detail:10 days |