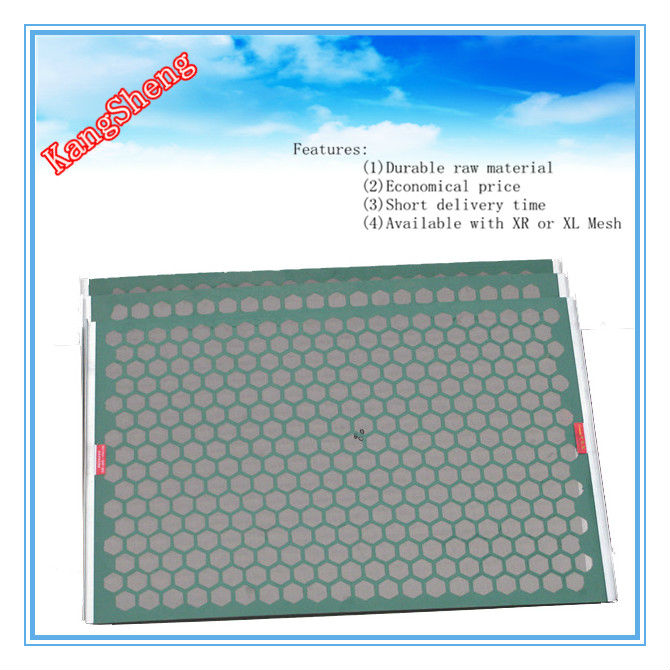

Drilling solid control system oil shale shaker screen

| Condition:New | Type:Linear,Mine Sieving Mesh/ Perforated Metal Mesh | Application:drilling solid control system oil shale shaker screen,Well drilling | Place of Origin:Hebei China (Mainland) |

| Brand Name:kangsheng | Model Number:Derrick/Brandt/Swaco | Certification::API | Material::SS304,SS316,SS316L |

| Filter Rating::99% | Usage:Liquid Filter | Size:customizable | MOQ:10pcs |

| Factory:yes | Weave Style::Plain Weave /Pyramid Weave |

Shaker Screens

Along with quality shakers,Kangsheng shale shaker screenmanufactures quality shaker replacement screens for a variaty of shaker products. Four decades of oilfield experience has allowed Kangsheng shale shaker screen to develop engineering and manufacturing methods and screen enhancements that easily surpass typical standards.

Why should I use Kangsheng shale Shaker Screens?

- 7 days service on all standard screens

- single, double, and triple layer screens available

- customized bonding patterns available upon request

- 100% warranty against components and workmanship

What can Kangsheng shale shaker screens do for me?

- Reduce the per hour drilling cost

- Improved penetration rates

- Extended fluid end life

- Extended Expendable Life

- Extended Bit Life

What replacement shaker screens are available?

| Brandt™ | Inrock™ | Triton™ | Kason™ |

| Derrick™ | National Oilwell™ | Vortex Fluid Systems™ | Kem-tron ™ |

| Fluid Systems™ | Swaco™ | Midwestern™ | Rumba ™ |

Can I have a custom shale shaker screen engineered for a specific application?

Kangsheng shale, has the engineering experience and manufacturing capability to solve the needs of this ever changing industry.

What custom shale shaker capabilities can we offer you?

- Experienced engineers

- Proven technology

- 20,000 square meter manufacturing facility

- Testing facilities

- Follow through

Your complete custom solutions are a phone call away.

As with any long standing industry institution, reputation is the key. For two decades, our clients have come to expect and have been delivered the quality they need, when they need it. They know they are getting superior workmanship and responsible service. We all know that is hard to come by, these days.

Derrick FLC500 Series Screen

Derrick FLC500 series screen is one kind of popular screen with most users. FLC500 screens can be used to replace shaker screens on FLC500 series shale shaker and mud cleaner. Including the PWP type and PMD type. There are different types via non-blanked area or filtration efficiency. Upon users' demand APP can meet your different requirements. Our common mesh are sized API20-450. Kindly find following basic FLC500 series screen parameters

Derrick FLC500 Series Screen | |

| Mesh | API20---API450 |

Dimension | Length:1050mm (41 3/10”) |

| Width: 697mm (27 2/5”) | |

Weight | PWP: 6.0kg (13.2lb) |

| PMD: 7.5kg (16.5lb) | |

| Screen layer | 2 or 3 Layers |

| Wire mesh material | S.S304 ,S.S316 (Customizable) |

| Frame material | Carbon steel |

Derrick FLC2000 Series Screen

FLC2000 Series screen is another kind of shaker screen for Derrick shale shaker and mud cleaner. FLC2000 shaker screen also can be called 48x30 screen. They are also hook strip shaker screen. And tensioned by Derrick special tensioning bolts. We have FLC2000 PWP and FLC2000 PMD types screen. Common screen mesh is from API20-450.

Please find following parameters of FLC2000 series shaker screen

Derrick FLC2000 Series Screen | |

| Mesh | API20---API450 |

Dimension | Length:1053mm (41 1/2”) |

| Width: 697mm (27 2/5”) | |

Weight | PWP: 4.2kg (9.24lb) |

| PMD: 5.8kg (12.76lb) | |

| Screen layer | 2 or 3 Layers |

| Wire mesh material | S.S304 ,S.S316 (Customizable) |

| Frame material | Carbon steel |

| Packaging Detail:2pcs per cartons, 5 cartons per wood case. |

| Delivery Detail:Within 10 days according to your quantity. |