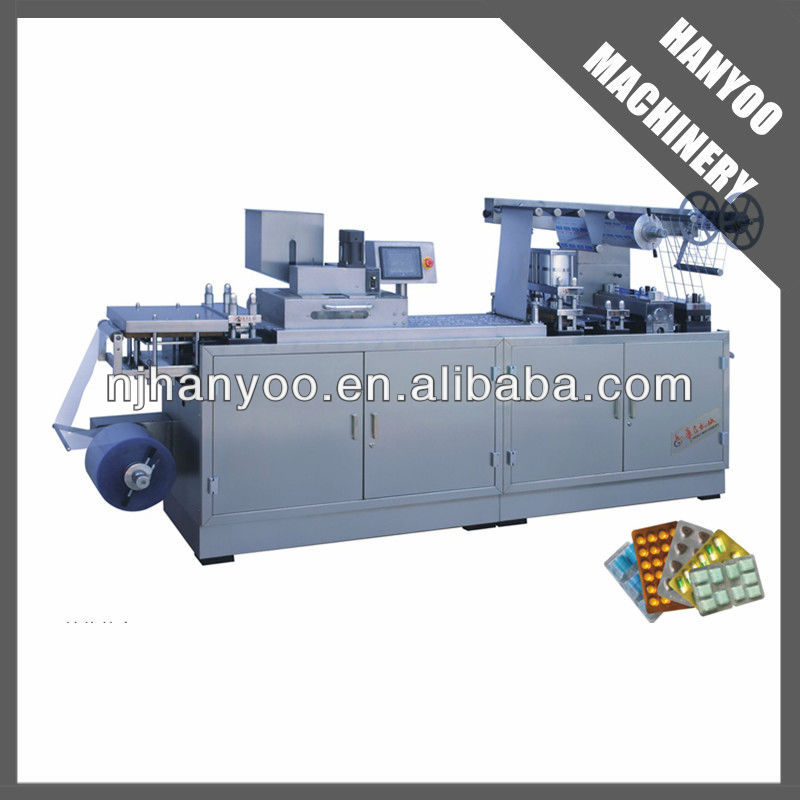

DPP-250A Automatic Aluminum Plastic Capsule Blister Machine

| Type:Blister Packaging Machine | Condition:New | Application:Food,Beverage,Commodity,Medical,Machinery & Hardware | Automatic Grade:Automatic |

| Driven Type:Electric | Voltage:220V | Power:6KW | Place of Origin:Jiangsu China (Mainland) |

| Brand Name:HANYOO | Model Number:DPP-250A | Weight:1500KG | Certification:ISO9001:2008; CE |

| Warranty:All Life Warranty | After-sales Service Provided:Engineers available to service machinery overseas | Name:Automatic Blister Packing Machine | Usage:For Commodity Blister Packaging |

| Certificate:ISO9001:2008; CE |

DPP-250A Automatic Aluminum PLASTIC Blister Packing Machine

DPP-250A Automatic Aluminum Plastic blister packing machine | |

| Application | The machine is new product which is improved based on customer’s requirements. It’s suitable for packaging of all kinds of liquid and solid in medium & pharmaceutical factory, health medicine factory, hospital preparation lab, food industry, electronic industry, hardware industry, etc. It can protect the material from steam or dust, improve product packing degree, and increase the additional value. The machine is used to produce many kinds of products. |

| Features | (1) Travel scope can be adjusted. Mould is located by located groove so that it’s easy to change mould. The machine heats the PP through conduction and forms it through pressing and frothing. (2) The material is fed automatically. The mould and feeding equipment can be designed as user’s requirements. (3) The heating moulds will automatically separate when the machine stops, which contributes to protect the material between them and extend the machine’s life. (4) The equipment of trace pressing, batch number printing and scrap-collecting can be chose. (5) Manipulator grip and tow wrapper, straight to-and-fro running, synchronize accurately and stably. (6) Speed is shifted by step-less transducer; the operation panel of PC cycle (can be Adopt interface of human-machine). |

- Installing and Commission:we will install and test the machine in best working condition before shipment. If customer requires our technician to adjusting the machine and train technician at arrival place, we will send technician there. All our expenses including round-trip air ticket to the nearest airport, local conveyance to your factory, Lodging&Boarding expenses shall be payable by you. In case the stay of our technician, the service charges $50 per day will be charged extra.

- Warranty period:one year for fully machine guarantee. And in this year if the machine broken caused by mechanical problem, all of the spare part is free. The service of the machine all though the machine’s life.

| No. | Item | Technical data | |

| 1 | Blanking frequency | 10-45 times/min,1-5 sheet/times | |

| 2 | Adjustable scope of feed travel | Standard:10-140mm,the max scope 150mm | |

| 3 | Sheet specification | Standard: 80 mm×57mm Designed as user’s requirement, and the max size: 270×120mm | |

| 4 | The max forming area and depth | 270mm×120mm×25mm | |

5 | Wrapper | PVC | Length: 250mm, thickness: 0.15-0.5mm |

| PTP | Length: 250mm, thickness: 0.02-0.35mm | ||

| Dialysis paper | Length:250mm,specification: 50-100 gram: | ||

Inside diameter of wrapper scroll | 70-76mm | ||

6 | Power of heating | Forming heating | 1.5KW |

| Heat-sealing | 1.5KW | ||

| 7 | Main motor power | 1.5KW | |

| 8 | Power supply | According to user’s requirement | |

| 9 | Capacity of air compressor (provide for oneself) | ≥0.2m3/min Pressure: 0.4~0.6MPa | |

| 10 | Mould cooling | Water supply: 60L/h | |

11 | Overall dimension | whole | 3345mm×635mm×1560mm |

| fission | 1670mm×635mm×1560mm 1675mm×635mm×1560mm | ||

| 12 | Weight | 1500Kg | |

| 13 | Apply to | Packaging of capsule, tablet, small pill, candy, food and electronic parts. Need know size of sample. Painting the drawing and make the mould according to the sample. | |

WELCOME SEND US EMAIL FOR INQUIRY MAHCINE LATEST PRICES!

| Packaging Detail:Wooden Case |

| Delivery Detail:25 Working Days |