Double drum roller compactor

| Machine Type:Granulator | Condition:New | Product Type:Fertilizer | Place of Origin:Jiangsu China (Mainland) |

| Brand Name:SG | Model Number:SG-360A | Voltage:Customized | Power(W):Customized |

| Dimension(L*W*H):Customized | Weight:Customized | After-sales Service Provided:Engineers available to service machinery overseas | applications:dry inorganic powder |

| working method:two counter-rotating rollers hydraulic compacting | roller material:CrMo | hydraulic press:yes | process flow:compact-crush-screen |

| density:doubling | recyclable:yes | sample test:available | final products:high strength |

| wt.:6 t |

Double drum roller compactoroperating principle:

The double drum roller compactor adopts the couple roller. Between the rollers, there is certain gap. Using double output shaft reduction machine, makes the couple roller in phase and run face to face. One group of roller axle seat is fixed and another group of roller axle seat is slipped. With the support of the pressure of hydraulic cylinder, they are close to each other and the hydraulic system can has the action of compensation and protection. In the surface of the roller, the hole (arc trough) of many shapes and same size are arrayed. According to the different compression rate of the materials, choose the trough of one roller aiming at the trough of another roller, or peak to trough. Two rollers is arranged in horizon. The powder material on itself weight is compulsorily feed into the gap between two rollers over the rollers continuously and equally. When the material enters into the gripping area, it is gripped by the roller. With the continuous turning or the roller, the occupied space of the material is less and less and gradually compressed and reaches the max value of the formation pressure. Then, the pressure gradually reduces. The flakes due to its elasticity and self weight breaks off the arc trough, and enter into the cutting and granulation device and sieves into the granules.

Double drum roller compactortechnical parameter:

a).roller diameter: 360mm available width: 180mm

b).roller speed: 3-26rpm.

c).screw feeder: 7.5kw motor frequency conversion speed adjusting, discharing device with 1.5kw transducer speed adjustment.

d).accumulator pre-pressurization: 6Mpa

e).allowable max. formation pressure rate: 65kN/cm

f). powder flaking thickness: 6-8mm

g).flaking productivity: 2.5-3t/h

h).grinding grain size: as per customer request: (usually about 2mm)

i). grinding productivity ≥1000kg/h

j). flaking principal machine power: 30kw

k).Installed capacity: about 50kw

l).dimension (L×W×H) : 2350×2000×2400

m).weight about 10t

n). output:1000-1200kg/h

o).granularity:1-5mm

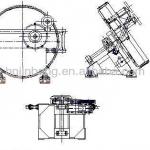

Double drum roller compactor components:

1) Ration feeding device: Composed of raw material silo and star type charger with fixed amount transportation, 1.1kw power, 6L/rpm, frequency conversion speed adjustment.

2) Screw feeder: Composed of charger with 7.5kw frequency conversion speed adjusting motor, taper helix, agitator knife, taper charger with observation window and feeding bucket. This is to further finish degasification and pre-compress the powder.

3) Compactor: Composed of fixed axle seat and slipped axle seat, two alloy steel rollers, two hydraulic cylinder and pump, double output reduction machine, Type GIICL drum jugged shaft coupling and 30kw electromotor set.

4) Grinding machine: Grinding chamber, cutting principal axis, 19 pieces of multi-teeth rotation knife and comb plate composes the grinding chamber. The principal axis driven by 4kw motor to rotate cut the flakes in high feed. The cutting speed is 750~900rpm.

5) Granulator: Composed of granulation chamber, granulation principal axis, 10 pieces of turning cut knife and the U type screen mesh (grain size as per customer request) with the hole diameter 0.5~5mm. 5.5kw motor-wheel drives the principal axis to granulating. The granulation turning speed: 150~250rpm.

6) Electrical control cabinet: Composed of electrical control box, frequency conversion speed adjusting controller, ammeter, voltmeter, instruction light, button, voltage conversion switch, etc.

7) Vibrating screen: (one set) the grinded material from the grinding and granulator is screened into the grain by this machine and recycled powder. SFJH100×2C

8) Bucket hoisting machine HL160, HL200, HL250. Equipped based on the request.

Double drum roller compactor applications:

1.fertilizer:

Potassium Sulfate(SOP), potassium chloride, Russia red potassium, potassium nitrate, ammonium chloride, Ammonium Phosphate Monobasic, Diammonium phosphate(DAP), NPK compound fertilizer, import Russia Potassium Sulfate(SOP), ground phosphorite, NH4SO4, concentrated superphosphate, humic acid etc.

2.powder material

zinc oxide, lead oxide, calcium chloride, calcium phosphate, High test bleaching powder, cryolite, chemical inhibitor, silica, Isophthalodinitrile etc.

3.FGD gypsum

Note:It takes potassium sulphate(SOP) for example, vary in accordance with the material to be granulated.

Our factory

Final products

Double drum roller compactor applications

Double drum roller compactor production line

Differenct between Double drum roller compactor Model A and Model B

Double drum roller compactor consists of screw feeder and double counter-rotating rollers

Double drum roller compactor's peripheral equipments

Double drum roller compactor primarily processed steps

Double drum roller compactor's rollers and final products' shapes

Double drum roller compactor's products variable shapes

Double drum roller compactor line is being loaded in one 40ft. container (Model SG-360A)

| Packaging Detail:Pictured in the specification of Double drum roller compactor |

| Delivery Detail:25 Days per unit |