DK8 Lightweight EPS Wall Panel Machine,Concrete wall panel machine

| Condition:New | Automatic Grade:Automatic | Production Capacity:130000㎡/year | Place of Origin:Fujian China (Mainland) |

| Brand Name:DK | Model Number:DK8 lightweight wall panel machine | Dimension(L*W*H):4500X420X380cm | Features:Automatic and less labor |

| Certification:ISO9001 | After-sales Service Provided:Engineers available to service machinery overseas | type:lightweight EPS wall panel machine |

Lightweight EPS Wall Panel Machine,Concrete Wall Panel Machine

Description

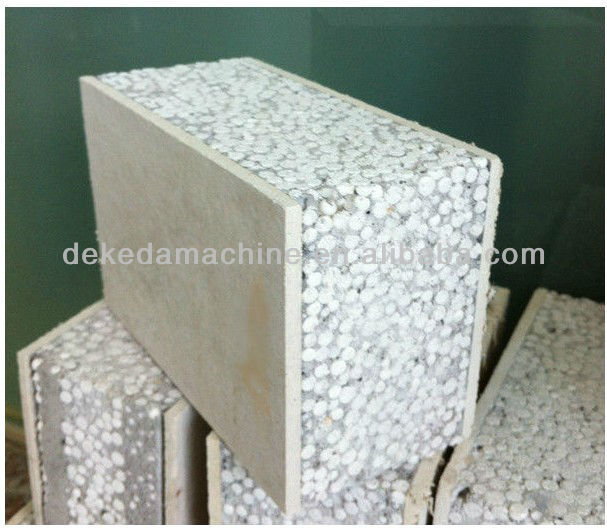

It is new-designed wall pannel making machine. The precast concrete wall pannel is a non-load bearing compound panel,which is made by cement,fly ash,EPS and covered by calcium silicate board.Compared with other wall material,it possesses the following features: light-weight, installing conveniently, heat and sound insulation,superiorwaterproof and fireproof,seismic and moisture resistance,easy decoration and size can be adjusted conveniently.Furthermore,it can be easy to cut and make channels according to construction need.

Compared the new type wall panel(thickness:75mm) with the block(120mm),it less 75mm.So it can increase 4.26sqm of wakable area per 100sqm.Therefore,the product has got a high popularity in building construction.

Raw material of wallboard machine

1.Gelled material--Mg Cement or sulphate aluminium cement

2.Reinforce material--fiberglass mesh

3.Heat insulation material-- Polyphenyl board,extruded sheet and rock wool board

4.Aggregate-- Straw, rice husk, fly ash, pearlier or silver sand

Molding Machine

The Technical Data of Moding Machine

| Function | Molding System | |

| Feed-in Volume | 17 cubic meter | |

| Finished Wall Panel Specification | 3000*600*75/90/100/150/200mm | |

| Output of Wall Panel with Different Thickness | 75mm | 12pcs |

| 90mm | 10pcs | |

| 100mm | 9pcs | |

| 150mm | 7pcs | |

| 200mm | 5pcs | |

| Hydraulic Unit | Motor power | 2.2kw |

| Pistom diameter | 180mm | |

| Operating stroke | 400mm | |

| Operating pressure | 3-4Mpa | |

| Molding Time | 2h(high alumina cement) | |

| Net Weight | 5T | |

| Component | main machine,hydraulic pressure station,mould | |

JQ1000-Mixer

The Technical Data of Mixer

| Type | Lifting Bucket | JQ1000 |

| Feed-in Volume | 1600L | 1600L |

| Discharging Volume | 1000L | 1000L |

| Max Size of Aggregate | 5mm | 5mm |

| Speed of Mixng Blade | 27.4r/min | 27.4r/min |

| Numbers of Mixing Blade | 4pcs | 4pcs |

| Style No. of Mixing Motor | XWD11-7-160-6-35 | |

| Power of Mixing Motor | 11kw | 11kw |

| Style No. of Winch | 500.3 | --- |

| Power of Winch | 4.5kw/i=20.27 | --- |

| Height of unloading | 1500mm | 1500mm |

| Sytle No. of Water Pump Motor | 3 phase self-sucking pump | |

| Power of Water Pump Motor | 0.75+11kw | 0.75+11kw |

| Dimension in Operation | 3939*4743*4364mm | 3939*1575*5736mm |

| Dimension in Transportation | 3939*2575*2547mm | 3939*1575*2457mm |

| Net Weight | 5.5T | 5T |

Demoulding Flip Stacker

Technical Data of Demoulding Flip Stacker

| Function | pull the finished wall panel out from the molding machine,push them together and turn 90 degrees to the designated location , and then transported to the storage yard by forklift. | |

| Motor Power | Motor for Hydraulic Pressure Station | 4kw |

| Traveling Motor | XWD3-4-47 3kw | |

| Demoulding Device | XWD1-3-59-4 11kw | |

| Cynlinder Power | Wall Panel Pushing Device | 980mm |

| Turnover Cylinder | 650mm | |

| Capacity/set | thickness:75mm | 12pcs |

| 90mm | 10pcs | |

| 100mm | 9pcs | |

| 150mm | 7pcs | |

| 200mm | 5pcs | |

| Dimension | 4312*3664*1150mm | |

| Component | Motor of Hydraulic Pressure Station,Turnover Cylinder,Demoulding Device,Wall Panel Pushing Device,Traveling Motor,Electric Control Cabinet | |

Slip Casting Machine

Technical Data of Slip Casting Machine

| The Capacity of Casting Pump | 6m³/h |

| Working Pressure | 1.5Mpa |

| Power of Motor | 5.5kw |

| Speed of Motor | 1440r/min |

| Number of Plunger Type Cylinder | 2 |

| Inside Diameter of Discharging Liquid Rubber Pipe | 51mm(2") |

| Inside Diamete of Feed-in Liquid Rubber Pipe | 64mm(2.5") |

| Packaging Detail:As customers' requirements for concrete wall panel machine. |

| Delivery Detail:30-45days against receiving deposit for wall panel machine |