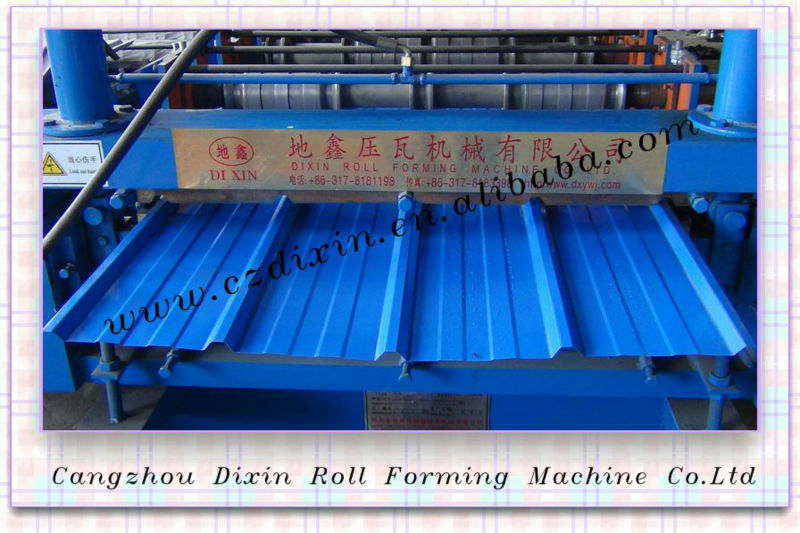

DIXIN 900/1080-225-15 wall panel roll forming machine

| Condition:New | Type:Tile Forming Machine | Tile Type:Colored Steel | Use:Roof |

| Production Capacity:10-12m/min | Place of Origin:Hebei China (Mainland) | Brand Name:DIXIN | Model Number:900/1080-225-15 |

| Power(W):3kw | Voltage:380v or at buyer`s requirment | Dimension(L*W*H):6.0m*1.3m*1.0m (L*W*H) | Weight:about 3.2 T |

| Certification:CE | Warranty:12month | After-sales Service Provided:Engineers available to service machinery overseas | material spec:colored steel sheet, galvanized steel sheet, aluminium sheet |

| raw thickness of coil sheet:0.3-0.8mm | shaft material:high grade NO.45 carbon wrought steel | 9. number of forming steps:9 rows |

CZDIXIN 900/1080-225-15 wall panel roll forming machine

Technical parameters:

1. material spec: colored steel sheet, galvanized steel sheet, aluminium sheet

- thickness of coil sheet: 0.3-0.8mm

- roller material: high grade NO.45 forged steel, with hard chrome plating on the surface of roller with thickness 0.05mm

- shaft material: high grade NO.45 carbon wrought steel

- cutting blade: Cr12 mould steel with quenched treatment

- diameter of shaft: 70mm

- thickness of medium plate: 14mm

- main frame: 300H/U steel

- number of forming steps: 9 rows

- productivity: 10-12m/min

- main motor power: 3kw

- hydraulic station power: 3kw

- hydraulic pressure: 10-12MPa

- controlling system: PLC computer control

- appearance sizes: 6.0m*1.3m*1.0m (L*W*H)

- total weight: about 2.5 tons

- Voltage: 380V 3Phase 60Hz or at buyer’s requirement

Equipment maintenance

maintenance of roof panel roll forming machine is quite easy. We recommend that you regularly feed lubricant to the machine gear, chain and moving parts to reduce friction and avoid rusting. Make sure the power lines are properly connected before starting the machine, and at regular intervals, change the gear oil and hydraulic oil.

Packaging

our roof panel roll forming machine is wrapped in a waterproof package

Service

we provide a one year warranty and lifelong technical support will be provided

we can send our technicians to you to give you on-site training. The training period would be for no more than one week with the customer paying for the visa, return ticket, food, accommodations and a daily wage of US50.

| Packaging Detail:our roof panel roll forming machine is warpped in a waterproof package |

| Delivery Detail:within 30 days after buyer`s reseived DLC from buyer`s bank |