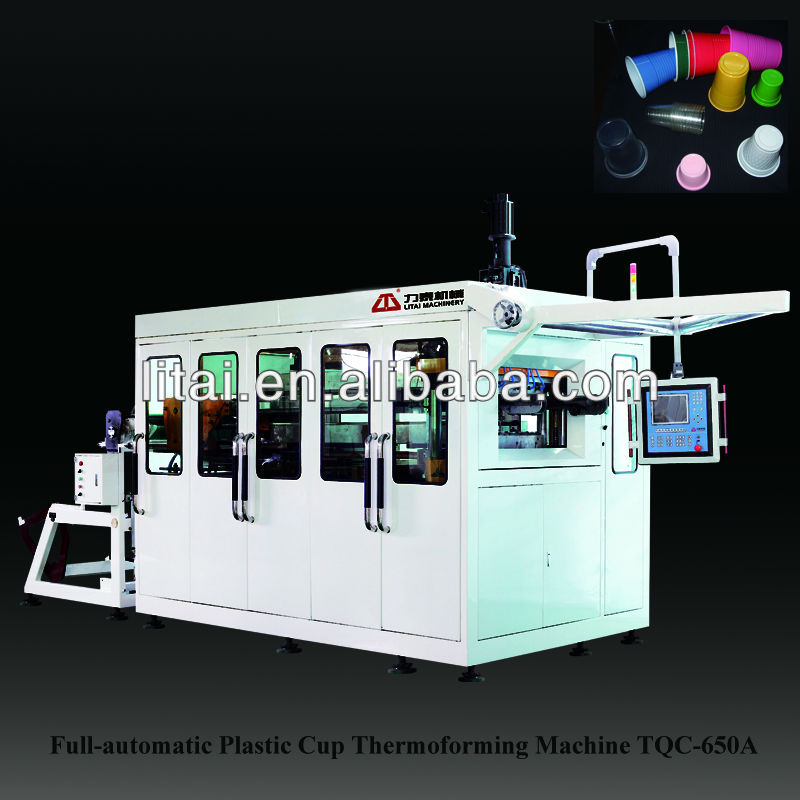

Disposable Plastic Cup Forming Machine

| Condition:New | Automatic Grade:Automatic | Usage:Plastic Forming Machine | Place of Origin:Zhejiang China (Mainland) |

| Brand Name:LITAI | Model Number:TQC-650B | Voltage:According to requirements | Power(W):55kw |

| Dimension(L*W*H):6000mm x 2000mm x 2700mm | Weight:4.5T | Certification:CE | Warranty:One Year |

| After-sales Service Provided:Engineers available to service machinery overseas | Hydraulic System:PLC&Touch Screen Control | Processing Type:Plastic Thermoforming Machine | Thermoforming Type:Forming speed:35cylce/time |

| 7oz cup capacity::42,000cups/hr | Plug::Servo Motor | Sheet Feeding::Servo Motor | Suitable Material::PP/PS/PET/HIPS/PVC |

| Suitable Sheet Thickness::0.2mm - 2.0mm | Forming Height::Max. 130mm | Forming Area::650mm x 320mm |

Our machines videos:

- Full-automatic Plastic Cup Thermoforming Machine TQC-650B video: http://youtu.be/pgIzWsRuCcA

- PP/PS Extrusion line TJ-670 video: http://youtu.be/Z-0w0yEH4h8

- Plastic Cup Production Line video: http://youtu.be/f4LvgIY05wc

- More machnes videos: http://www.youtube.com/user/Cloudylv

Application area:

The machine produces plastic products likedisposable plastic cups, plastic bowls, ice cream cups, cold drinking cups, yoghurt cups, coffee cups, jelly cups, plastic dishes, plastic trays, plastic lids, food containers, plastic boxes, vessel for fast-foodetc.

It suits for formingPP, HIPS, PVC, PS, PET sheet.

Functions:

1.It adoptsPLC&Touch Screen:Siemens,Germany.

2.Hanging type for Microcomputer.The frame is exported from Germany.

3.Four pillarsto fix machine

4.Servo motordrivers control sheet feeding.

5.Servo motordrivers control stretching mechanism.

6.Electric Control Panelcan be separate from thermoforming machine when it's working

7.Automatically lubricatethe movement parts of thermoforming machine.

8.Oven systemautomatically move out when the power is off.

9.Hydraulic pressure systemdrives thermoforming mechanism.

10.The machine's whole track can move backward:Easy to change & install the moulds. To shorten the time for changing the moulds, it increases the productivity & saves the time & money.

11.Automatic loadfor sheet roll:It's a motorized "un-rewinder" to feed the film into the thermoforming machine. No need to pull the sheet directly, through a separate un-rewinder that unrolls the sheet, sensor can induce & decreases the tension prior of going into the thermoforming area.

12.PID temperature control.

Technical Parameter:

| Suitable Sheet: | PP/PS/HIPS/PVC/PET |

| Forming Area: | 650mm x 320 mm |

| Forming Depth(Max) | 130mm |

| Sheet thickness: | 0.3mm-2.0mm |

| Sheet width(max): | 650mm |

| Max. Sheet Roll of Diameter: | 800mm |

| Forming Speed(max): | ≤35 times/min |

| Adjustable Travel: | 100mm-350mm |

| Oil Pump Motor: | 11kw, 6grades |

| Plug Motor Power: | 4.4kw |

| Feeding Motor Power: | 3.0kw |

| Rewinding Motor Power: | 0.37kw |

| Heating Power: | 60kw |

| Rated Power: | 80kw |

| Actual Power: | 55kw |

| Compressed Air: | About 0.6-0.8pa/1.6M3 |

| Heating Type: | Top + bottom IR Ceramic Heaters |

| Temperature Control Module | PID, K-type |

| Type of Mould | Multi cavity 1-4rows |

| Cutting Type: | In-mold cutting automatically |

| Water Supply: | About 0.5M3/H |

| Overall Dimension(mm): | about L6000×W2000×H2700 |

| Weight: | About 4.5T |

| Packaging Detail:Wooden case packing:oil first,then film,finslly wooden case packing. |

| Delivery Detail:40days. |