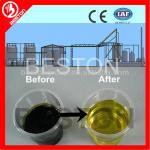

Dirty Oil Decolorization Plant CHINA

| Condition:New | Place of Origin:Chongqing China (Mainland) | Brand Name:Chongqing Yangjiang | Model Number:YJ-TY-11 |

| Usage:Lubricant Oil | name:Dirty Oil Decolorization Plant CHINA | Technology:vacuum distillation | Raw Material:dirty oil |

| Function:decolorize dirty oil to yellow base | Capacity:11 tons per day | Final product:yellow base oil | Regenerating rate:more than 85% |

| Flash point:220 ℃ | Viscosity index:120 | Ash content:0.005%W/W |

Dirty Oil Decontamination Plant CHINA

Brief description

Dirty Oil Decolorization Plant CHINA is particularly suitable to regenerate used engine oil including diesel engine oil, gasoline engine oil,motor oil,ship engine oil, truck oil, and used hydraulic oil, other used machinery lubrication oil

Dirty Oil Decolorization Plant CHINA can remove water, impurity, acid base, and tiny impurity dispersed in oil such as carbon particles, heavy metal ions, deep oxides, as well as bad substance such as colloid and bitumen. Thus, the clarity of oil is recovered, engine oil quality improved, performance of engine restored, abrasion reduced, these would ensure correct operation of lubricant system of a engine and extend the life time of engine oil and engine as well.

Working principle

Because the waste oil contain too much contamination, including non-hydrocarbon, alkene, polycyclic aromatic hydrocarbon, metal hydronium, impurities, metal particles, asphaltene and colloid etc. and due to the traditional technology only can refine the waste oil to base oil, cant use directly, so our company is researching the new technology about distilling machine, which can distill all kinds of waste oil into clean oil, easy to operation, and the lower operation cost.

Dirty Oil Decolorization Plant CHINA adopt physicochemical actions to polymerize,passivate, absorb and eliminate impurities and harmful contamination. We research a new chemical alkaline complex catalyst, which can restore andregeneration the Waste oil to clean oil, save the component of the oil.

YANGJIANG provide all used lube oil recycling equipment and technology. This is more than simply used lubrication oil disposal,we are not just purify used oil,instead, we developed an amazing regeneration process than can reclaim all kinds of waste black lube oil to clean base oil.This is the most effective process for lube oil recycling , TY vacuum system is to refine waste oil in a batch process.Waste lube oil after pre-treatment ,will be pumped into a catalyst reactor we will add two kinds catalyst blend with oil and heat in a distillation kettle under vacuum

Advantage:

1.Low cost, cost is 30$ for refine one tons used motor oil

2.Easy to operate,low operation cost, only 1-2 workers can control the machine.

3.The machine can recycle gasoline motor oil, diesel motor oil, all kinds of engine oil, and other lubricant oil to clean oil.

4.Environmental friendly. This machine is full-enclosed, there is no any harmful smell come out form the machine, colloid, oxid, acid, pitch will be converted to oil sludge, can be use as bitumen and fuel.

5.85% high recycling rate. This includes 6-8% diesel and gasoline mixture,80-85% base oil and 8-10% oil sludge.

6.Efficient vacuum systems

7.High quality refined oil, no any discoloration caused by oxidation, no any bad smelling.

Dirty Oil Decolorization Plant CHINA | |

Base oil Recovery Rate: | |

| Component | Percentage(%) |

| Gasoline&diesel oil | 7% |

| Base oil | 80-85%(abase on your water content) |

| Residue | 7-10% |

This machine can convert used black mixed lube oil to yellow base oil.This is the most effective process for lube oil recycling , TY vacuum system is to refine waste oil in a batch process.Waste lube oil after pre-treatment ,will be pumped into a catalyst reactor we will add two kinds catalyst blend with oil and heat in a distillation kettle under vacuum. As the temperature in the kettle rises, various cuts are liberated and rise as vapors, to be condensed in a condenser. The condensed products are available as different products corresponding to various kettle temperatures .

Finally, the process ends when the residual material in the kettle does not vaporize, even at a temperature of around 350Celcius. At this point, the heating in the distillation process is stopped and the process is essentially complete.

Using advanced vacuum distillation technology,which is different from the traditional sulfuric acid and the flocculation process. Traditional process uses sulfuric, water glass(Na2O.mSiO2 ,1%),TEPA(Tetraethylenepentamine)C8H23N5,1-2%) and activity clay(25%) to treat used motor oil. These additives are expensive and TEPA is very difficult to buy.

Our company`s vacuum distillation technology, just need add two kinds of catalyst, which is cheap and easy to buy.

Dirty Oil Decolorization Plant CHINA | ||||

Recycled base oil parameter: | ||||

No | Item | Unit | Technical data | |

| Light base oil | Medium/heavy base oil | |||

| 1 | Viscosity(40°C) | mm2/s | 16~32 | 28~72 |

| 2 | Viscosity index | ≥99 | >110 | |

| 3 | Appearance | Transparency | Transparency | |

| 4 | Color index | ASTMD 1500 Number | ≤1 | ≤2 |

| 5 | Pour point | °C | -15 | -10 |

| 6 | Water content | %(W/W) | ≤0.05 | ≤0.05 |

| 7 | Flash point(open) | °C | ≥180 | ≥210 |

| 8 | Ash content | %(W/W) | 0.005 | 0.005 |

| 9 | Carbon residue | %(W/W) | ≤0.13 | ≤0.13 |

| 10 | Corrosion(copper,100°C,3h) | Qualified | Qualified | |

| 11 | Acidity | mgKOH/g | ≤0.05 | ≤0.05 |

| Packaging Detail:To be packed in strong wooden cases, suitable for long distance ocean or freight transportation as well as changing climate and with good resistance to moisture and shocks. |

| Delivery Detail:within 30 days |