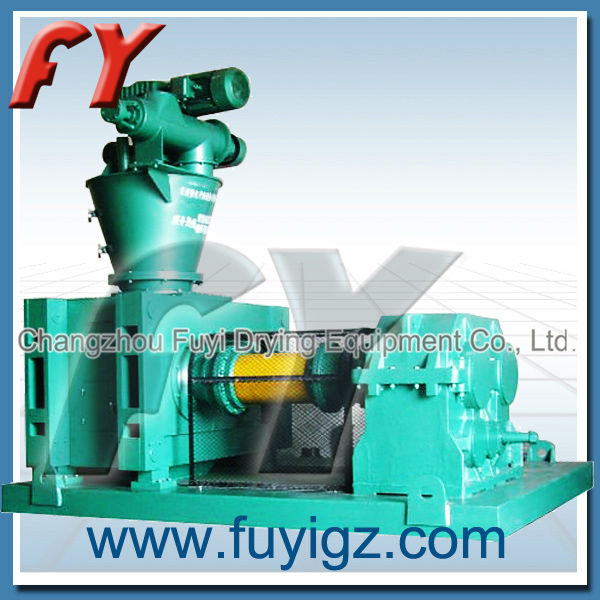

DH450 Fertilizer Granules Briquetting Machinery

| Product Type:Fertilizer | Place of Origin:Jiangsu China (Mainland) | Brand Name:FUYI | Model Number:DH450 |

| After-sales Service Provided:Engineers available to service machinery overseas | Application:Fertilizer Granules Briquetting Machinery | Material:Carbon Steel or Stainless Steel | Sample Test:Available |

| Hardness:Greater than 28N | Adhesives:No | Water:No | Roller material:CrMo |

| Machine Type:Grabulator | Hydraulic system:available | Final granules shape:2-5mm |

Raw materials are sent into hopper by quantitative feeder , compactors use the pair of roller with the hole roll, leaving certain gap and rotation with the same speed reversely. Shaft holders of one group of rolls are fixed, and the other one of group can slide to help the hydraulic cylinder press the rolls for abutting closely against each other. Many arc grooves with the same shape and size are arrayed regularly on the roll surface. In accordance with different compressing ratios of target materials, the wave trough of arc groove of one roll shall be directed at that of one roll. When two rolls parallel each other horizontally, powder grained materials are, continuously and evenly fed in the gap between two rolls by means of their gravities and through a forced charger from above of two rolls. After entering the nip area, the materials are gradually nipped by the rolls. With continuous rotation of the rolls, the space that the materials occupy reduces gradually and is compressed step by step and reaches the maximum shaping pressure. And then, as the pressure reduces gradually later, pressed blocks drop off the arc grooves of the rolls for recovered elasticity and gravity of the flaking machine and enter a crushing device for crushing and then enter a sieving device for sieving. At last, grained products are obtained. The powder materials and large particles which are substandard will return to bucket elevator and enter into the next process with new products.

Technical parameters

Type | DH360 | DH450 | DH650 | DH800 |

Roller diameter (mm) | Φ360 | Φ450 | Φ650 | Φ800 |

Valid usable width (mm) | 150-220 | 180-270 | 290-330 | 380-450 |

Roller speed (rpm) | 14,18,24,30 | 10-25 | 10-25 | 10-25 |

Max forming pressure (MPa) | 18 | 21 | 2100 | 2900 |

Max rolled sheet thickness (mm) | 8 | 12 | 16 | 25 |

Rolled sheet output*(kg/h) | 1600 | 3000 | 8000 | 12000-18000 |

Finished product size (mm) | 0.5-6 | 0.5-6 | 0.5-6 | 0.5-6 |

Finished product output*(kg) | 800-1200 | 1800-2500 | 3500-4200 | 6000-12000 |

Main machine power (kw) | 37 | 55 | 90 | 210 |

Total installed capacity (kw) | 55 | 90 | 175 | 298 |

Contour dimensions(L×W×H) | 2000×2000×4600 | 2500×2500×5600 | 2800×3900×6300 | 3500x4200 x8500 |

Total weight (t) | 10 | 15 | 25 | 33 |

Notice:Rolled sheet output, finished product output are reference values and the screen is determined according to the nature of the materials.

Briquetting production line (we can design different briquetting line for our customers)

Final products and roller shape

From tesing to manufactuing the machines

Delivery

Clients installation site

Automatic Electric Control Cabinet

Our services

Fuyi has designed and manufactured roller presses and equipments for briquetting and compacting NPK fertilizer, powder, chemical, minerals, etc, since 2006. We take care of green field projects as well as of existing plants. Our services cover material tests, process layout, engineering, and supply of complete granulating plants or key equipments, guidance of installation and commissioning, training.

Also, the company manufactures and supplies equipment for drying equipments and dust collector machines.

Extensive experience and best quality production facilities guarantee a smooth workflow from start to finish.

Welcome our sincere clients come to visit out factory.

| Packaging Detail:1. Big machines packed in nude.2. Spare parts packed in wooden case.3. If our clients have any special requirement, we will pack as request. |

| Delivery Detail:50 days |