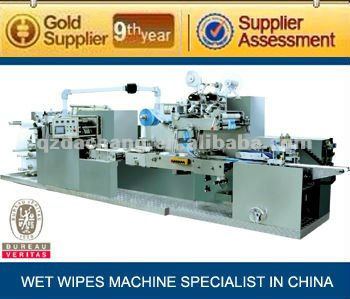

DC-2060B Full-auto High-speed Wet Paper Machinery

| Condition:New | Place of Origin:Fujian China (Mainland) | Brand Name:DaChang | Model Number:DC-2060B |

| Voltage:380V,50HZ | Power(W):30KW | Dimension(L*W*H):8000X1520X2350mm | Weight:6000kg |

| Certification:CE,TUV,CE | Warranty:one year | After-sales Service Provided:Engineers available to service machinery overseas | Main form of machine:Stainless steel |

| Motor:Servo |

DC-2060B high speed full automatic wet wipes machine

Main technical parameter | |

| Motive factor | 30KW |

| Power supply | three phase 380V,50Hz |

| Suitable material | Spun lace non-woven fabrics, Hot-rolling non-woven fabrics. |

| Quality of material | 40g/~80g/ |

| Production size(unfolded) | 180*160 mm(L*W) |

| Production size(folded) | 90*65-75mm (L*W) |

| Production speed | 80 packs/min |

| Packing specification | 5-30 pcs/bag |

| Raw material size | Width=320,Diameter ≤1200 |

| Machine size(mm) | 6800*1520*2350L* W * H |

| Wastage rate | ≤3% |

Main technical parameter of packing machine | |

| Packing film | width ≤240 ;Diameter ≤400 |

| Label | Width≤60 ;Diameter ≤300 |

Main structure of the machine | |

1.Unwinding the spunlace material by transduser, tension control automaticlly. 2.Spunlace material cutting device,the cylinder separate the cutting blade. 3.Two labeling device 4.Cutting a hole on the film by the machine automatically 5.The circumgyrated form sealing device. 6.Electromotion differential gear, adjusting phase without stopping the machine. 7.The relatived postion of the puching hole,Labeling, and the eyemark are enactmented in the PLC. 8.The main electric brand adopts famous brand SIMENCE. 9.Main machine is frame form. | |

Main configure of the machine | |

1.Spunlace cutting device. 2.Spunlace vertical folding device. 3.Spunlace wetting device, adopt founder form. 4.Cutting wet tissue device. Adopting high-speed steel cutting blade. 5.Spunlace transversed folding device. It can adjust the folding size and the folding shape. The machine has automatic counting and stacking device .The counting pieces can be set in the PLC. The stacker adopts sever motor driver. 6.The device of cutting a hole on the film by the machine automatically. 7.Two sets of label stick device, they can be used at the same time, and also can be used solely. 8.Packing film device. 9.The packing film sealing vertically device, and the cylinder open-closed sealing device. 10.The packing form sealing transverly mdevice, and the cylinder open-closed sealing evice. The folding machine, packing machine, and the feeding film frequency conversion, and timing. Three transducer can run automatically at the same time. 11.Closed gear box+ step belt and coupling running form. 12.Electric control model includes automatic and manual,to meet the demand in the running . 13 Each motor can be started and stop solely, setting in the PLC. 14.The hole machine has four urgent stop button, when press, the machine will stop. | |

| Packaging Detail:Standard seaworthy wooden case |

| Delivery Detail:60 -120 days when get your advance payment |