CS-SUBM Qspan Machine/cold roll forming machine/roll forming machine

| Place of Origin:Liaoning China (Mainland) | Brand Name:CS | Model Number:CS-A/P/Q/S | Material of rollers:45# steel, quenched |

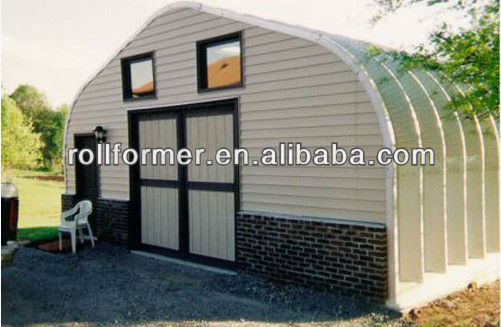

| Material of cutting:Cr12 moV high-quenching steel | Step of rollers:13 | Use:Roof of the factory, warehouse, garage, stadium, museum etc. | Span:As your requirement |

| Driving device:Hydraulic / Mechanical | Spare parts:Given together with the machine for free | Controlling system:CNC |

CS-SUBM Arch Roof Roll Forming Machine

Introduction:Our advanced UCM type machine can make 4 different buildings shapes,only with one machine.

We manufacture 3 generations to meet marketing as follows:

SUBM-Generation First

Generation First:Two-step producing.

First step for straight panel.

Second step for cured panel.

Straight Part:Feeding-Forming-Cutting

Curing Part:Feeding-Curving

SUBM-Generation Second

Generation Second:Revolution of producing process.One step for both straight panel and curved panel.Compared to Generation first ,the labor cost will be reduced 30%.The working speed at project site will be improved over 20%.

Feeding-Forming-Cutting-Curving

SUBM-Generation Third

Generation Three:With diesel truck and 8T crane(15m long leg).The construction can drive the truck to the project site.Only step you can finish the panels you need,and no workers are needed to hold and carry the panel.When the panels are ready,the crane on the machine can lift and fix them easily.Compared to Generation first,the labor cost will be reduced over 80%.The working speed at project site will be improved 70%.

Feeding-Forming-Cutting-Curving-Lifting

| Packaging Detail:he machine with its accessories can be loaded into one 40"HQ container |

| Delivery Detail:Within 20-30 working days after receiving 30% down payment |